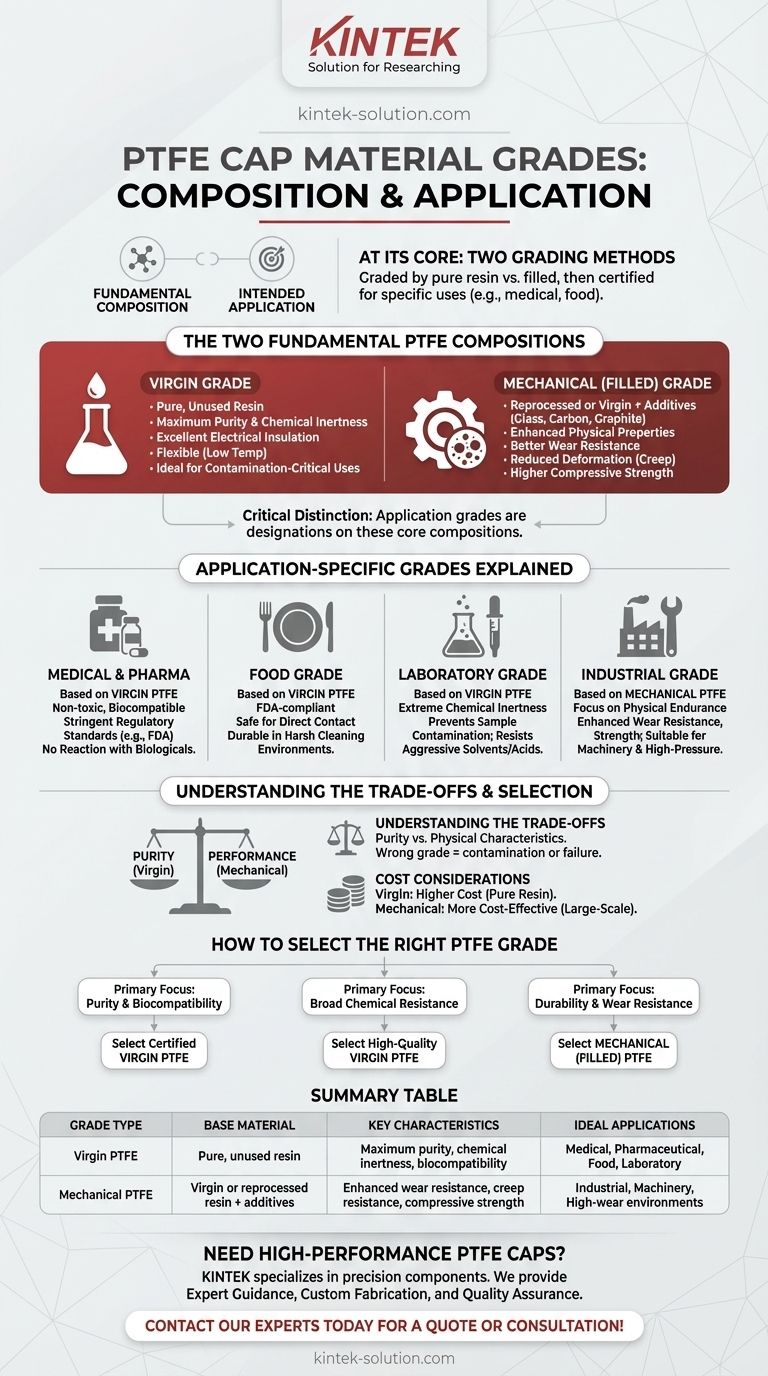

At its core, PTFE material for caps is graded in two primary ways: by its fundamental composition and by its intended application. The main compositions are virgin PTFE, made from pure resin for high-purity uses, and mechanical PTFE, which may be reprocessed or contain fillers to enhance physical properties. These compositions are then certified for applications such as medical, food, laboratory, or industrial use.

The critical distinction to understand is that application-based grades (like "food grade" or "medical grade") are designations applied to a fundamental material composition. The choice between pure virgin PTFE and additive-enhanced mechanical PTFE is the most important decision driving performance and suitability.

The Two Fundamental PTFE Compositions

Before looking at application labels, you must first understand the base material. All PTFE grades start as one of two types.

Virgin Grade: Purity and Chemical Inertness

Virgin PTFE is produced directly from pure, unused PTFE resin without any additives. This is the highest purity form of the material.

Its key characteristics are exceptional chemical resistance, excellent electrical insulation, and flexibility, especially at low temperatures.

Because it contains no other substances, it is the default choice for applications where contamination is a critical concern.

Mechanical (Filled) Grade: Enhanced Physical Properties

Mechanical PTFE, often called filled PTFE, uses reprocessed resin or combines virgin resin with additives like glass, carbon, or graphite.

These fillers are not impurities; they are intentionally added to improve specific physical properties.

This grade can offer significantly better wear resistance, reduced deformation under load (creep), and higher compressive strength compared to virgin PTFE.

Application-Specific Grades Explained

The application grades you see advertised are essentially certifications or formulations of the fundamental compositions for specific environments.

Medical and Pharmaceutical Grade

This grade is almost exclusively made from virgin PTFE. Its non-toxic, chemically inert, and biocompatible properties are paramount.

Materials designated for medical or pharmaceutical use must meet stringent regulatory standards, such as those from the FDA, to ensure they do not react with biological tissues or drug formulations.

Food Grade

Similar to medical grade, food-grade PTFE is based on virgin PTFE to ensure purity and prevent leaching into consumables.

It must be FDA-compliant, guaranteeing that it is safe for direct contact with food and beverages. Its resistance to harsh cleaning chemicals and acids makes it highly durable in processing environments.

Laboratory Grade

Laboratory-grade caps are typically made from virgin PTFE due to the need for extreme chemical inertness.

In analytical settings, it is crucial that the cap does not react with or contaminate the sample, especially when working with aggressive solvents or acids.

Industrial Grade

This is the most common application for mechanical (filled) PTFE. The focus here is on physical endurance rather than absolute purity.

Fillers are chosen to enhance properties like wear resistance for moving parts, thermal conductivity, or strength for high-pressure seals, making it suitable for demanding machinery and equipment.

Understanding the Trade-offs

Selecting the right grade requires balancing purity against physical performance.

Purity vs. Performance

The primary trade-off is between the absolute purity of virgin PTFE and the superior physical characteristics of mechanical PTFE.

Using a mechanical grade in a high-purity application could cause contamination, while using a virgin grade in a high-wear industrial setting could lead to premature failure.

Cost Considerations

Generally, virgin PTFE is more expensive due to the cost of pure, unprocessed resin.

Mechanical grades can be more cost-effective, particularly if using reprocessed materials, making them a practical choice for large-scale industrial applications where high purity is not a requirement.

How to Select the Right PTFE Grade

Your final choice should be dictated entirely by the demands of your application.

- If your primary focus is purity and biocompatibility (Medical, Pharma, Food): You must select a cap made from certified virgin PTFE to meet regulatory requirements and prevent contamination.

- If your primary focus is broad chemical resistance (General Laboratory): A high-quality virgin PTFE is the safest and most reliable choice to ensure sample integrity.

- If your primary focus is durability and wear resistance (Industrial Machinery): Choose a mechanical (filled) PTFE grade with additives specifically designed to handle the physical stresses of your environment.

Ultimately, aligning the material's core composition with your specific performance requirements is the key to a successful application.

Summary Table:

| Grade Type | Base Material | Key Characteristics | Ideal Applications |

|---|---|---|---|

| Virgin PTFE | Pure, unused resin | Maximum purity, chemical inertness, biocompatibility | Medical, Pharmaceutical, Food, Laboratory |

| Mechanical (Filled) PTFE | Virgin or reprocessed resin with additives (e.g., glass, carbon) | Enhanced wear resistance, creep resistance, compressive strength | Industrial, Machinery, High-wear environments |

Need High-Performance PTFE Caps?

Choosing the correct PTFE grade is critical for your application's success and longevity. KINTEK specializes in manufacturing precision PTFE components, including caps, seals, and liners.

We provide:

- Expert Guidance: Our team will help you select the ideal virgin or mechanical PTFE grade for your specific needs in the semiconductor, medical, laboratory, or industrial sectors.

- Custom Fabrication: From prototypes to high-volume orders, we tailor our components to your exact specifications.

- Quality Assurance: We prioritize precision production to ensure reliability and performance.

Let's discuss your project requirements. Contact our experts today for a quote or consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials