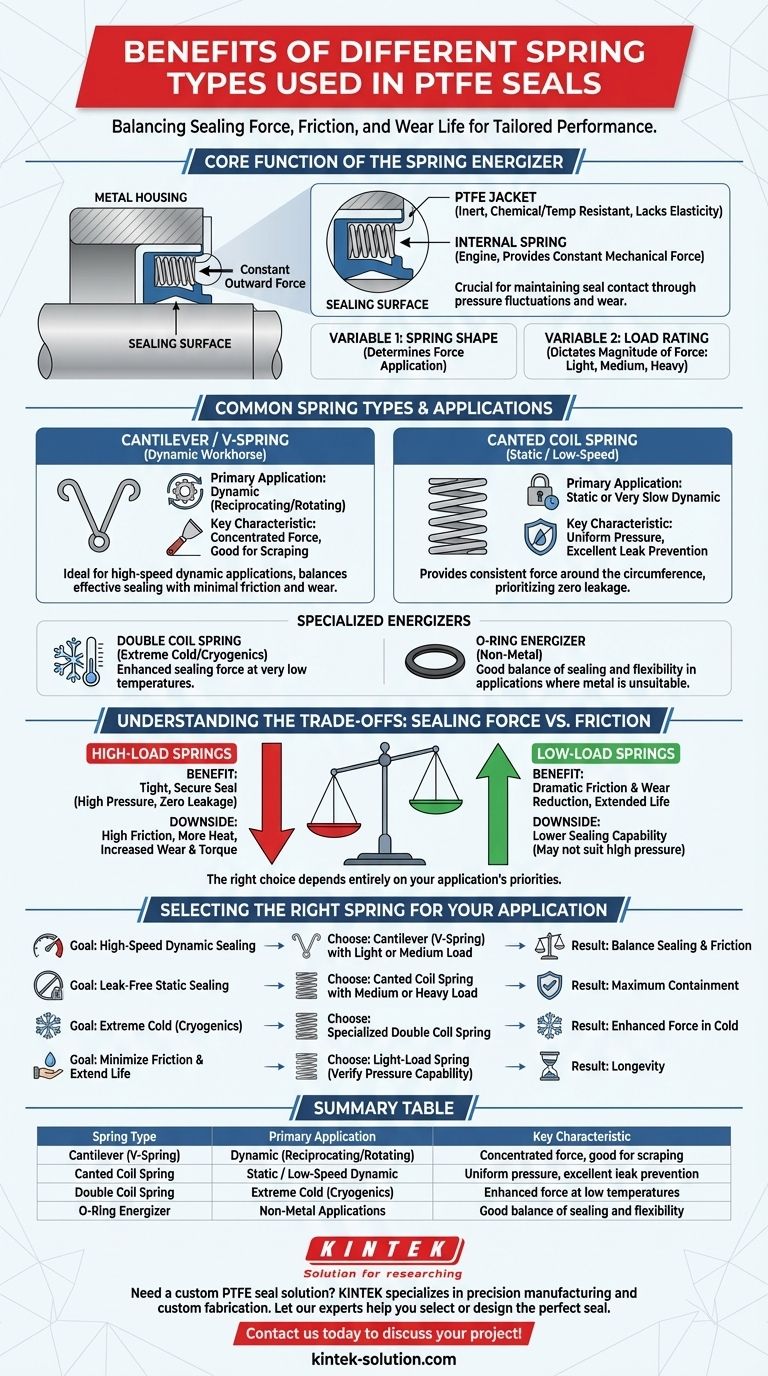

The choice of spring energizer is the single most critical factor in tailoring a PTFE seal's performance to a specific task. Different spring types and load ratings are designed to create a precise balance between sealing force, friction, and wear life. The primary spring types include cantilever (V-spring) styles for dynamic applications and canted coil springs for high-force static sealing, each available in various loads to meet exact operational requirements.

The inert PTFE jacket provides the chemical and temperature resistance, but it lacks elasticity. The internal spring is the engine of the seal, providing the constant mechanical force necessary to maintain a seal. The spring's design—its shape and load—directly dictates the seal's behavior, creating a fundamental trade-off between aggressive sealing and low-friction, long-life performance.

The Core Function of the Spring Energizer

A PTFE seal combines a durable, low-friction polymer jacket with a metallic spring. Understanding how these two components work together is essential to selecting the right design.

Why PTFE Needs a Spring

The key benefit of PTFE is its incredible resistance to chemicals and extreme temperatures, but it is not a naturally elastic material like rubber.

Once installed, a PTFE jacket will not rebound on its own to maintain pressure against a sealing surface. The internal spring provides this critical, continuous outward force, ensuring the seal lip stays in contact with the hardware through pressure fluctuations and wear.

The Two Variables: Shape and Load

Every spring energizer is defined by two key characteristics that you must consider for your application.

First is the spring's shape, which determines how it applies force to the seal lip. Second is the load rating (typically light, medium, or heavy), which dictates the magnitude of that force.

Common Spring Types and Their Applications

While many variations exist, most designs fall into a few primary categories, each suited for different operational conditions.

Cantilever or V-Spring

Also known as a finger spring, this design is the workhorse for dynamic applications. It functions like a series of small leaf springs, applying a concentrated force at the point of contact.

This focused pressure is highly effective at scraping fluids, while its design provides good flexibility, making it ideal for reciprocating (back-and-forth) or rotating motion.

Canted Coil Spring

A canted coil spring provides a very consistent and uniform pressure around the entire circumference of the seal lip.

This makes it exceptionally effective for static (non-moving) or very slow dynamic applications where leak prevention is the absolute top priority. The uniform load minimizes potential leak paths.

Specialized Energizers

For extreme environments, specialized springs are available. A double coil spring can be used in static cryogenic applications to provide enhanced sealing force at very low temperatures.

In applications where a metal spring is not suitable, an O-ring energizer can be used instead, offering a good balance of sealing and flexibility.

Understanding the Trade-offs: Sealing Force vs. Friction

The decision to use a light, medium, or heavy load spring is a critical engineering trade-off. There is no single "best" option; the right choice depends entirely on your application's priorities.

High-Load Springs

A heavy-load spring exerts the maximum force on the sealing lip. This creates a highly secure, tight seal that is effective against high pressures and in applications where zero leakage is tolerated.

The downside is significantly higher friction. This generates more heat, increases torque requirements, and accelerates wear on both the seal and the mating hardware.

Low-Load Springs

A light-load spring minimizes contact pressure. The primary benefit is a dramatic reduction in friction and wear, which is ideal for high-speed dynamic applications or when extending the service life of the components is crucial.

The trade-off is a lower sealing capability. While often sufficient, a light-load spring may not be suitable for high-pressure systems or applications where containment is critical.

Selecting the Right Spring for Your Application

Your optimal choice depends directly on your primary operational goal. Use these guidelines to make an informed decision.

- If your primary focus is high-speed dynamic sealing: Choose a cantilever (V-spring) with a light or medium load to balance effective sealing with minimal friction and wear.

- If your primary focus is leak-free static sealing: A canted coil spring with a medium or heavy load will provide the uniform, high force needed for maximum containment.

- If your primary focus is sealing in extreme cold (cryogenics): Consider a specialized double coil spring to ensure sufficient sealing force when materials contract.

- If your primary focus is minimizing friction and extending service life: Prioritize a light-load spring, but verify that its sealing capability is sufficient for your system's pressure.

Matching the spring's characteristics to your application's demands is the key to unlocking the full performance potential of a PTFE seal.

Summary Table:

| Spring Type | Primary Application | Key Characteristic |

|---|---|---|

| Cantilever (V-Spring) | Dynamic (Reciprocating/Rotating) | Concentrated force, good for scraping |

| Canted Coil Spring | Static / Low-Speed Dynamic | Uniform pressure, excellent leak prevention |

| Double Coil Spring | Extreme Cold (Cryogenics) | Enhanced force at low temperatures |

| O-Ring Energizer | Non-Metal Applications | Good balance of sealing and flexibility |

Need a custom PTFE seal solution for your semiconductor, medical, or industrial application? The right spring energizer is critical for performance. KINTEK specializes in precision manufacturing of PTFE components (seals, liners, labware) and offers custom fabrication from prototypes to high-volume orders. Let our experts help you select or design the perfect seal for your specific requirements. Contact us today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining