The primary fabrication services for Polytetrafluoroethylene (PTFE) are shearing, slitting, laser cutting, stamping, die cutting, compression molding, and machining. These processes are specifically adapted to handle PTFE's unique combination of softness, chemical inertness, and thermal stability. The ideal method is determined by the final part's complexity, required precision, and production volume.

Choosing the right PTFE fabrication service is not just about the shape you need; it's about respecting the material's unique properties. The key is to match the manufacturing process to the material's characteristics to ensure the final component performs reliably in its intended environment.

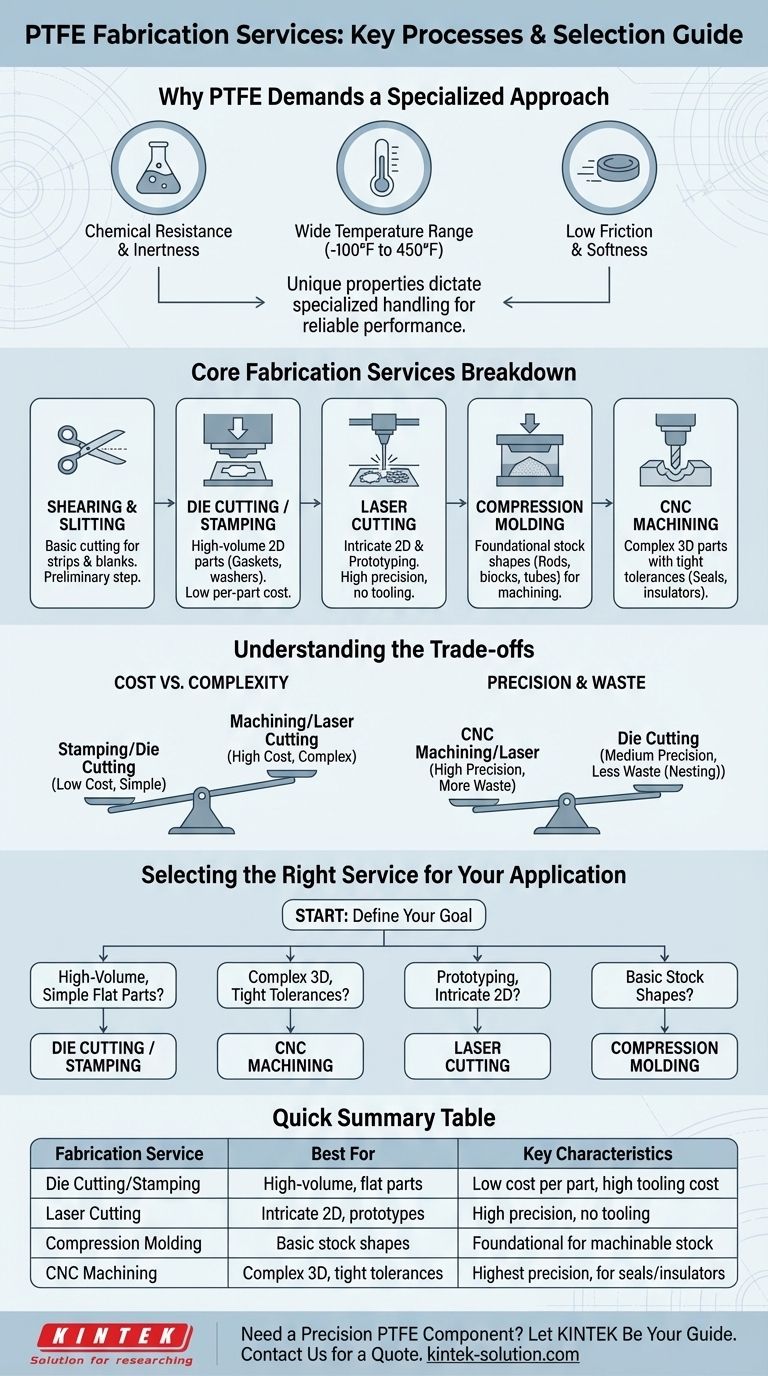

Why PTFE Fabrication Demands a Specialized Approach

Standard manufacturing processes often fail when applied to PTFE. Its distinct properties, which make it invaluable in demanding applications, also dictate how it must be handled and shaped.

Understanding PTFE's Core Properties

PTFE, widely known by the brand name Teflon, is defined by several key characteristics. It has exceptional chemical resistance against acids, alkalis, and solvents, and operates across a wide temperature range (from -100°F to 450°F).

Its other defining traits are an extremely low coefficient of friction, making it non-stick and self-lubricating, along with excellent electrical insulation properties.

The Impact on Manufacturing

These properties directly influence fabrication. For example, its softness and low friction mean it requires extremely sharp tooling and specific machining speeds to avoid deformation. Its thermal stability is high, but thermal expansion must be managed during processes like laser cutting to maintain dimensional accuracy.

A Breakdown of Key Fabrication Services

Each fabrication method is suited for producing different types of components, from simple flat gaskets to complex, high-precision insulators.

Shearing and Slitting

This is the most basic process, used to cut large sheets or rolls of PTFE into narrower strips or smaller rectangular blanks. It is a preliminary step for other processes or for creating simple liners and barriers.

Die Cutting and Stamping

These methods are ideal for high-volume production of flat, two-dimensional parts. A sharp steel-rule die is pressed into a sheet of PTFE to stamp out identical shapes like gaskets, washers, and simple seals.

Laser Cutting

For more intricate 2D geometries, laser cutting offers superior precision. A high-powered laser vaporizes the material to create clean, accurate cuts, perfect for complex gaskets or custom prototypes without the need for expensive tooling.

Compression Molding

This is a foundational process for creating basic, solid PTFE shapes. PTFE resin powder is compressed in a mold under heat and pressure to form stock materials like blocks, rods, rings, and tubes, which are then often machined into final parts.

Machining

Machining is the process of choice for complex, three-dimensional components with tight tolerances. Using stock shapes from compression molding, CNC machines can create highly precise parts like seals, O-rings, V-rings, nozzles, and electrical insulators.

Understanding the Trade-offs

Selecting a fabrication service involves balancing cost, precision, and production volume. There is no single "best" method; the right choice is always application-dependent.

Cost vs. Complexity

Stamping and die cutting have high initial tooling costs but a very low cost per part, making them ideal for high-volume runs of simple shapes. Conversely, machining and laser cutting have minimal setup costs but a higher cost per part, suiting them for prototyping and complex, low-volume production.

Precision and Tolerances

CNC machining offers the highest level of precision and the tightest dimensional tolerances, which is critical for components like dynamic seals and medical devices. Die cutting is less precise, while laser cutting offers excellent accuracy for flat parts.

Material Waste

Subtractive processes like machining inherently generate more material waste (scrap) than formative processes. Die cutting can be optimized by "nesting" parts closely together on a sheet, but some waste is unavoidable.

Selecting the Right Service for Your Application

Your final goal dictates the optimal fabrication path.

- If your primary focus is high-volume production of simple, flat parts (gaskets, washers): Die cutting or stamping offers the most cost-effective solution once tooling is created.

- If your primary focus is creating complex 3D components with tight tolerances (seals, insulators, nozzles): CNC machining from compression-molded stock is the required approach.

- If your primary focus is prototyping or low-volume production of intricate 2D shapes: Laser cutting provides the necessary precision and flexibility without high initial tooling costs.

- If your primary focus is producing basic stock shapes for further processing (rods, blocks): Compression molding is the foundational step before machining.

Matching the fabrication method to both the part geometry and PTFE's unique characteristics is the key to a successful outcome.

Summary Table:

| Fabrication Service | Best For | Key Characteristics |

|---|---|---|

| Die Cutting / Stamping | High-volume, flat parts (gaskets, washers) | Low cost per part, high tooling cost |

| Laser Cutting | Intricate 2D shapes, prototypes | High precision, no tooling, ideal for low volumes |

| Compression Molding | Basic stock shapes (rods, blocks, tubes) | Foundational process for creating machinable stock |

| CNC Machining | Complex 3D parts with tight tolerances | Highest precision, ideal for seals and insulators |

Need a Precision PTFE Component? Let KINTEK Be Your Guide.

Choosing the right fabrication method is critical for PTFE's performance. As specialists in manufacturing high-quality PTFE components (seals, liners, labware, and more), KINTEK has the expertise to guide you from prototype to high-volume production. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring your parts meet the highest standards of precision and reliability.

Contact us today to discuss your project requirements and get a quote. Our team is ready to help you select the optimal process for your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments