Machining Polytetrafluoroethylene (PTFE), commonly known as Teflon, presents a unique set of challenges. Unlike metals or harder plastics, the difficulty with PTFE arises not from its resistance to cutting, but from its extreme softness, low thermal conductivity, and high thermal expansion. These properties demand specialized techniques to prevent deformation, maintain dimensional accuracy, and achieve a clean finish.

The core challenge of machining PTFE is managing its instability. Its tendency to deform under pressure, expand with minimal heat, and creep over time means that traditional high-force machining methods will fail. Success requires a strategy of finesse, using exceptionally sharp tools, light cutting forces, and rigorous temperature control.

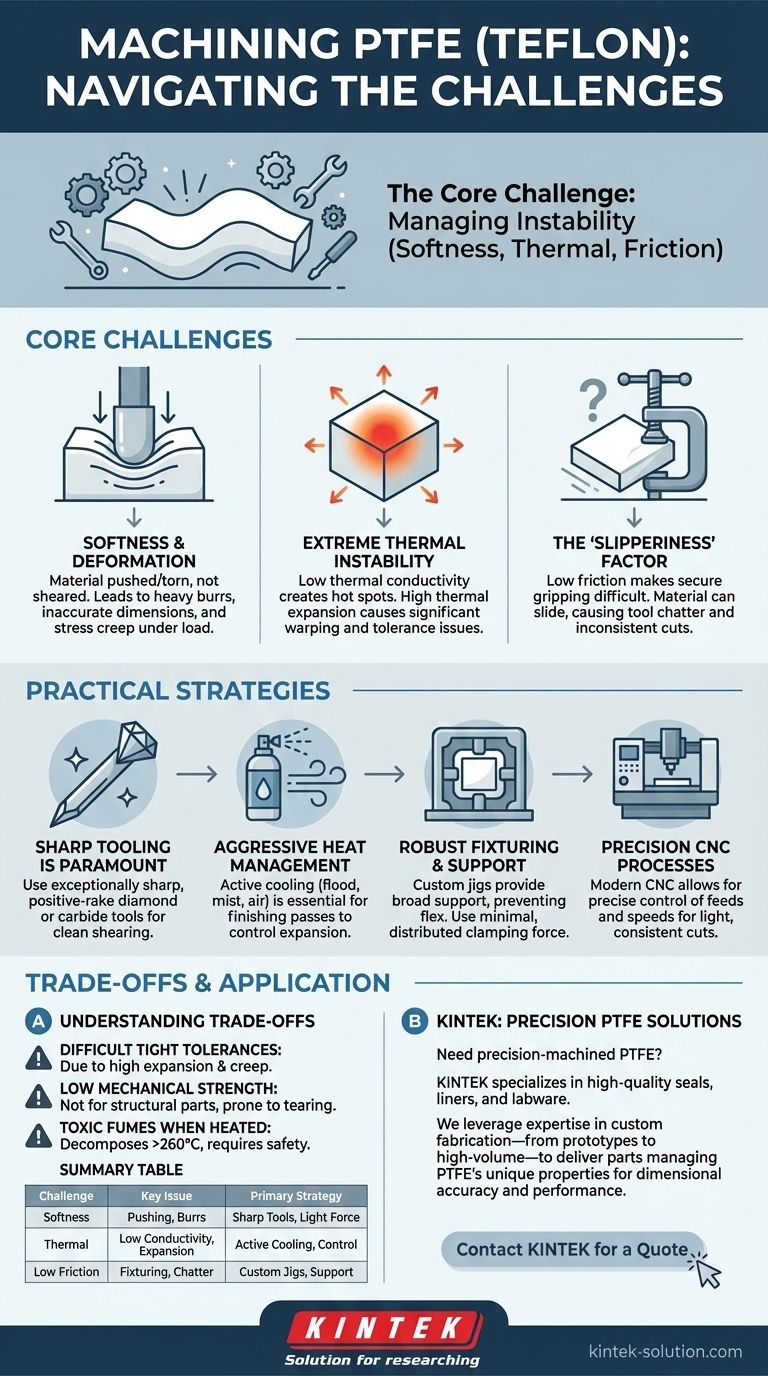

The Core Properties Driving Machining Difficulties

To machine PTFE effectively, you must first understand the fundamental material properties that make it so challenging. These characteristics are interconnected and influence every aspect of the fabrication process.

Softness and Deformation

PTFE is an exceptionally soft and malleable material. This leads to it being pushed or torn by the cutting tool rather than being cleanly sheared.

This behavior is the primary cause of heavy burr formation, which can be difficult to remove without damaging the part. The material's softness also means it is easily compressed and deformed by clamping pressure in fixtures, leading to inaccurate final dimensions once the part is released.

Furthermore, PTFE is subject to stress creep, meaning it will slowly deform over time when under a constant load, even at room temperature.

Extreme Thermal Instability

PTFE reacts significantly to temperature changes, which creates two major problems during machining.

First, it has very low thermal conductivity. Heat generated at the cutting edge does not dissipate quickly through the material. This creates localized hot spots that can cause the PTFE to warp or even break down.

Second, it has a very high coefficient ofthermal expansion. Even minor temperature increases from friction will cause the material to expand significantly, making it nearly impossible to hold tight tolerances. The part may be within spec while being machined, only to shrink out of spec as it cools.

The "Slipperiness" Factor (Low Friction)

PTFE has one of the lowest coefficients of friction of any solid. While this is its most famous property, it creates a machining headache.

The material's slipperiness makes it difficult to grip securely in chucks or vises without applying excessive force, which again leads to deformation. The low friction can also cause the material to slide away from the cutting tool, leading to tool chatter and an inconsistent cut.

Practical Strategies for Successful PTFE Machining

Overcoming the challenges of PTFE requires adapting your approach to accommodate its unique properties. The focus must be on minimizing force, controlling temperature, and providing robust support.

Tool Selection is Paramount

The single most important factor is the cutting tool itself. Tools must be exceptionally sharp with positive rake angles to ensure they are shearing the material cleanly.

Diamond and carbide tools are often recommended for their ability to maintain a razor-sharp edge. A dull tool will immediately begin to push the material, causing all the deformation and heating issues to cascade.

Managing Heat and Chips

Aggressive temperature control is critical for maintaining dimensional stability.

While coolants are not always required for roughing, they are essential for finishing passes where tolerance is key. Non-aromatic, water-soluble flood coolants or misting systems are effective at managing frictional heat. Pressurized air can also be used to clear chips and provide some cooling.

Fixturing and Material Support

Standard fixturing methods are often inadequate for PTFE. You must provide broad support to the workpiece to prevent it from flexing away from the cutting tool.

Custom jigs or fixtures that fully encapsulate the part are often necessary to hold it securely without distortion. Use minimal clamping pressure distributed over a wide surface area.

The Right Machining Process

Modern CNC techniques are well-suited for PTFE because they offer the high degree of control needed.

CNC milling, turning, and drilling allow for precise control over feeds and speeds, enabling the light, consistent cuts necessary for a good finish. Multi-axis machining can produce complex geometries while minimizing the need for re-fixturing, which reduces the risk of part deformation.

Understanding the Trade-offs of PTFE

While its properties make it ideal for certain applications, PTFE is not a universal solution. Understanding its inherent limitations is crucial for successful part design and material selection.

Difficulty with Tight Tolerances

Due to its high thermal expansion and tendency to creep, achieving and holding tight tolerances is the primary limitation of machining PTFE. Parts must often be inspected in a temperature-controlled environment after they have fully normalized.

Low Mechanical Strength

PTFE is a weak material in terms of mechanical properties. It has low tensile strength and is prone to tearing. It should not be used for structural components or in applications where it will be subjected to significant mechanical stress.

Chemical and Safety Considerations

While known for its chemical inertness, PTFE can react with alkali metals and highly reactive fluorinating agents.

Most importantly, when heated above 260°C (500°F), it begins to decompose and release toxic fumes. This is a critical safety consideration, reinforcing the need for excellent temperature control during machining.

Making the Right Choice for Your Application

Your approach to machining PTFE should be dictated by the final requirements of the component.

- If your primary focus is precision and complex geometry: Prioritize extremely sharp tooling, robust part support, and active cooling to manage thermal expansion during finishing passes.

- If your primary focus is high-volume production: Recognize that maintaining tight tolerances across a large batch will be difficult and may require post-machining stabilization or inspection steps.

- If your primary focus is mechanical strength: Acknowledge that PTFE is likely the wrong material and consider a more robust polymer like Nylon or PEEK.

Ultimately, mastering the machining of PTFE comes from treating it not as a plastic to be cut, but as an unstable material to be carefully shaped.

Summary Table:

| Challenge | Key Issue | Primary Strategy |

|---|---|---|

| Softness & Deformation | Pushing/tearing, burrs, stress creep | Exceptionally sharp tools, light cutting forces |

| Thermal Instability | Low conductivity, high expansion | Active cooling, temperature control |

| Low Friction | Difficult fixturing, tool chatter | Custom jigs, broad support |

Need precision-machined PTFE components that overcome these challenges?

KINTEK specializes in manufacturing high-quality PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We leverage our expertise in custom fabrication—from prototypes to high-volume orders—to deliver parts that meet your exact specifications, managing PTFE's unique properties to ensure dimensional accuracy and performance.

Contact KINTEK today for a quote and let our precision production solve your PTFE machining needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What regulatory standards does PTFE with fillers comply with? Ensuring Safety from Food to Pharma

- What are the characteristics of virgin PTFE gaskets? The Ultimate Guide to Pure PTFE Performance

- What are the key properties that make PTFE gaskets suitable for industrial applications? | KINTEK

- What are the main differences between FR4 and PTFE PCB laminate materials? Choose the Right Material for Your Application

- What are the common types of glass reinforcements used in PTFE-based materials? Optimize Performance for Your Application

- What industries commonly use PTFE bushings, and why? Solve Critical Engineering Challenges

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance

- What advantages does PTFE packing provide? Superior Chemical Resistance, Low Friction & Thermal Stability