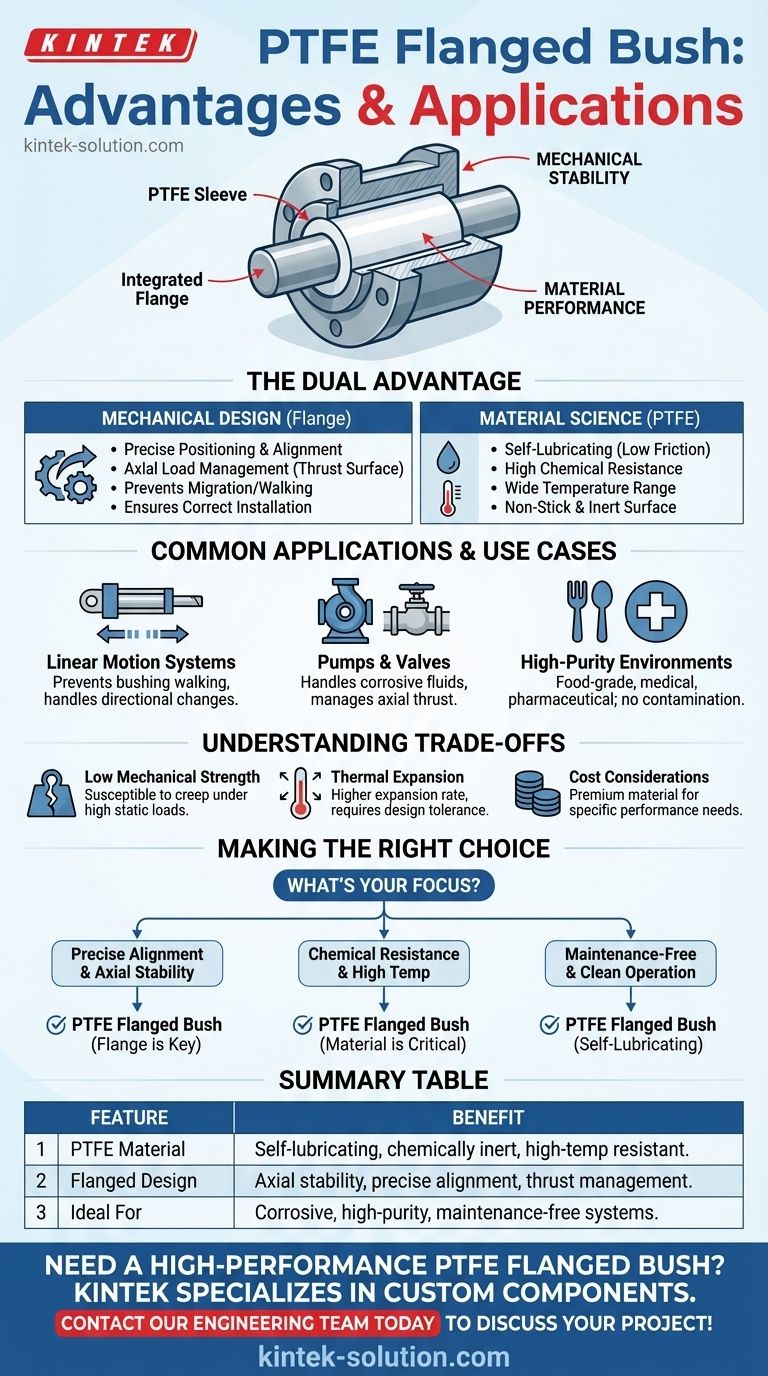

At its core, a PTFE flanged bush is a sleeve-like bearing made from Polytetrafluoroethylene (PTFE) that features an integrated rim, or flange, at one end. This design combines the exceptional material properties of PTFE—such as self-lubrication and high resistance to chemicals and temperature—with the mechanical advantage of a flange, which provides stability, aids in alignment, and prevents the bushing from being pushed through its housing.

The key is to understand that a PTFE flanged bush solves two problems at once: the flange addresses the mechanical need for precise positioning and axial load management, while the PTFE material addresses the operational need for low friction and high environmental resistance.

The Dual Advantage: Mechanical Design and Material Science

To fully grasp its value, it's essential to analyze the two distinct components of its design: the physical shape and the material it's made from.

The Flange: More Than Just a Rim

The flange is a critical feature for mechanical stability. It acts as a locating surface during installation, ensuring the bush is positioned correctly and squarely within its housing.

Most importantly, the flange provides a thrust surface. This means it can bear loads along the axis of the shaft (axial loads), preventing unwanted movement and ensuring the component remains locked in its intended position.

The PTFE Material: A Self-Sufficient Performer

PTFE, often known by its trademark name Teflon®, is a high-performance fluoropolymer with a unique combination of properties.

Its low coefficient of friction is one of the lowest of any solid material, creating a smooth, non-stick surface. This allows parts to move freely without external lubrication, making it self-lubricating.

Furthermore, PTFE offers outstanding chemical resistance against most acids and bases, is non-corrosive, and can withstand a wide range of temperatures. It also serves as an excellent electrical and thermal insulator.

Common Applications and Use Cases

The unique combination of the flange's stability and PTFE's properties makes this component ideal for specific demanding scenarios.

Linear Motion Systems

In applications where a shaft moves back and forth, the flange is crucial. It prevents the bushing from "walking" or migrating out of its housing due to repeated directional changes.

Pumps and Valves

The superior chemical resistance of PTFE makes it perfect for equipment handling corrosive fluids. The flange helps manage the axial thrust generated by rotating shafts and pressure differentials.

High-Purity or Food-Grade Environments

Because PTFE is inert, non-stick, and requires no external lubrication, it is often used in food processing, medical, and pharmaceutical equipment where contamination is a primary concern.

Understanding the Trade-offs and Limitations

While highly effective, a PTFE flanged bush is not a universal solution. An objective assessment requires understanding its limitations.

Low Mechanical Strength

PTFE is a relatively soft material. Under very high static loads, it can be susceptible to "creep" or cold flow, where the material slowly deforms over time. It is not suitable for high-impact or extremely high-load structural applications.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. This means it will expand and contract more significantly with temperature changes, a factor that must be accounted for in the design tolerances of the housing.

Cost Considerations

While readily available, PTFE is generally a more premium material compared to common alternatives like nylon or bronze bushings. Its selection is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE flanged bush is the correct component for your project.

- If your primary focus is precise alignment and axial stability: The flange is the key feature, ensuring the bushing is securely located and can handle thrust loads.

- If your primary focus is chemical resistance or high temperatures: The PTFE material is the critical benefit, protecting against corrosion and thermal degradation where other materials would fail.

- If your primary focus is maintenance-free, clean operation: The self-lubricating and non-stick nature of PTFE is ideal for sealed systems or applications where contamination is unacceptable.

Ultimately, selecting a PTFE flanged bush is a deliberate engineering choice for when mechanical positioning and superior material properties must converge.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Material | Self-lubricating, chemically inert, and high-temperature resistant. |

| Flanged Design | Provides axial stability, precise alignment, and thrust load management. |

| Ideal For | Corrosive environments, high-purity applications, and maintenance-free systems. |

Need a high-performance PTFE flanged bush for your application?

KINTEK specializes in manufacturing precision PTFE components, including custom flanged bushings, for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with custom fabrication capabilities—from prototypes to high-volume orders—to deliver a solution that meets your exact requirements for performance, durability, and chemical resistance.

Contact our engineering team today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability