In short, PTFE seals perform exceptionally well under pressurized conditions. They are specifically engineered to maintain a reliable seal on mating surfaces without leaking, even when subjected to significant fluid or gas pressure. This capability stems from a unique combination of material properties, including chemical inertness, thermal stability, and low friction.

The core takeaway is that while PTFE excels at handling pressure, its true performance in a dynamic system is dictated by the PV (Pressure × Velocity) value. Understanding this limit is the key to preventing premature wear and ensuring long-term reliability in applications with moving parts.

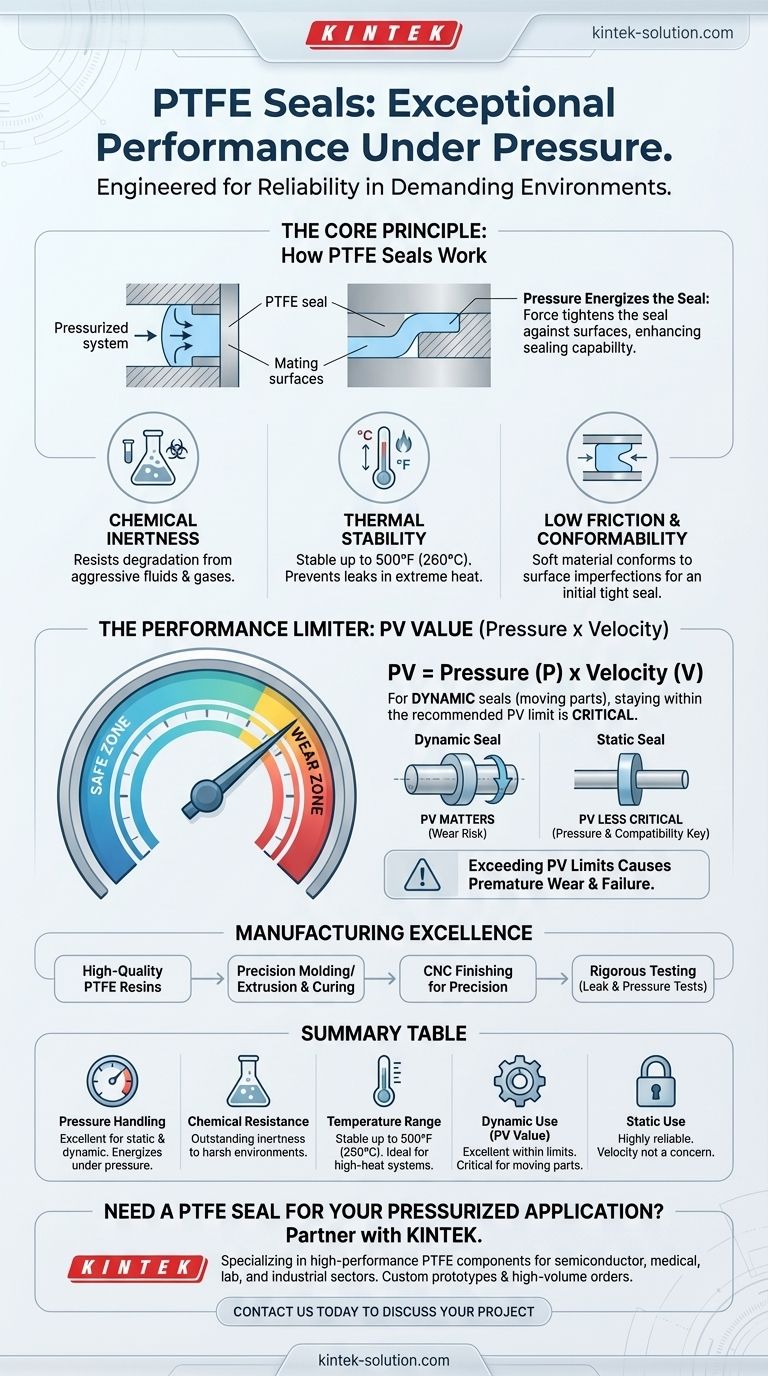

The Principles of PTFE Sealing Under Pressure

The effectiveness of a PTFE seal in a pressurized environment is not due to a single characteristic, but rather the interplay of several key material properties.

How Material Properties Create a Robust Seal

PTFE is inherently soft and formable. This allows the seal to conform perfectly to microscopic imperfections on mating surfaces, creating an exceptionally tight initial seal. When pressure is applied, it energizes the seal, forcing it more tightly against the surfaces and enhancing its sealing capability.

Exceptional Chemical Inertness

Pressurized systems often contain aggressive fluids or gases. PTFE exhibits outstanding chemical resistance, meaning it will not degrade, swell, or weaken when exposed to a vast range of chemicals. This ensures the seal's integrity and performance are maintained over its entire service life.

Stability Across a Wide Temperature Range

Pressure and temperature are often linked. PTFE seals are highly heat resistant, with some formulations maintaining their performance at temperatures as high as 500°F (260°C). Unlike other materials that can harden or degrade in extreme heat, PTFE remains stable, preventing leaks in high-temperature, high-pressure applications.

Understanding the Key Performance Limiter: The PV Value

While PTFE is an excellent choice for pressurized systems, it has a critical performance threshold, especially in dynamic applications involving movement. This is known as the PV value.

What is the PV Value?

The PV value is a crucial performance metric calculated by multiplying the Pressure (P) on the seal by the surface Velocity (V) of the moving part. It represents the combined mechanical and thermal stress the seal can endure.

The Impact of Exceeding PV Limits

PTFE performs best under moderate loads and speeds. If the combined pressure and velocity exceed the manufacturer's recommended PV value, the seal will experience accelerated wear. This is the most common cause of premature failure in dynamic PTFE sealing applications.

When to Prioritize PV Calculations

This limitation is paramount for dynamic seals, such as those on rotating shafts or reciprocating rods. For static seals, where there is no movement (Velocity = 0), the PV value is not a concern, and the seal's performance is primarily dictated by its pressure rating and material compatibility.

From Raw Material to Reliable Seal

The dependable performance of PTFE seals under pressure is also a direct result of a meticulous manufacturing and quality control process.

The Role of High-Quality Resins

The process begins with the selection of high-quality PTFE resins. These are molded or extruded into a basic shape, such as tubing, which forms the foundation of the final product.

Curing and Finishing for Precision

The shaped material undergoes a heat treatment process, often called curing or frittage, which enhances its mechanical strength and resistance properties. The final seals are then machined to precise dimensions using CNC equipment to ensure a perfect fit.

The Importance of Quality Testing

Reputable manufacturers conduct rigorous testing on finished seals, including leak and pressure tests. This final step verifies that each seal meets the required specifications and is ready to perform reliably in its intended pressurized application.

How to Apply This to Your Project

Your specific goal will determine how you should weigh the properties of PTFE.

- If your primary focus is static sealing with aggressive chemicals: PTFE is an excellent choice due to its superior chemical inertness and ability to conform to surfaces under pressure.

- If your primary focus is dynamic sealing (moving parts) under pressure: PTFE is highly effective, but you must calculate and operate within the specified PV value to ensure a long service life.

- If your primary focus is a high-temperature and high-pressure environment: PTFE's exceptional thermal stability makes it a leading candidate, capable of outperforming most common elastomers.

By understanding these core principles, you can confidently leverage the unique advantages of PTFE for your most demanding pressurized applications.

Summary Table:

| Performance Factor | PTFE Seal Performance | Key Consideration |

|---|---|---|

| Pressure Handling | Excellent for static and dynamic sealing | Seals energize under pressure for a tighter fit |

| Chemical Resistance | Outstanding inertness to aggressive fluids/gases | Maintains integrity in harsh environments |

| Temperature Range | Stable up to 500°F (260°C) | Ideal for high-temperature, high-pressure systems |

| Dynamic Use (PV Value) | Excellent within rated limits | Critical for moving parts; exceeding limits causes wear |

| Static Use | Highly reliable | No velocity concern; pressure and chemical compatibility are key |

Need a PTFE Seal for Your Pressurized Application? Partner with KINTEK.

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production process ensures every seal is engineered to handle your specific pressure, temperature, and chemical requirements, with rigorous testing for leak-proof reliability.

Whether you need custom prototypes or high-volume orders, we deliver solutions that excel under pressure. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- How do PTFE extruded rods contribute to electrical insulation? Ensure Uncompromising Performance in Harsh Environments

- Why is EPDM the preferred choice for pneumatic butterfly valves in water treatment systems? | KINTEK

- What are the key properties of PTFE bushings? Unlock Superior Performance in Harsh Environments

- How does wall thickness affect the yield strength and flexibility of PTFE liners? Optimize Performance for Your Application

- How does the corrosion resistance of Teflon gland fillers benefit chemical industry applications? Ensuring Safety and Reliability

- What types of industrial applications are Teflon Bellow Mechanical Seals best suited for? Excel in Harsh Chemical & High-Speed Environments

- What is the shape and material of the PTFE Lined Spacer? A Guide to Its Round Design and PTFE Benefits