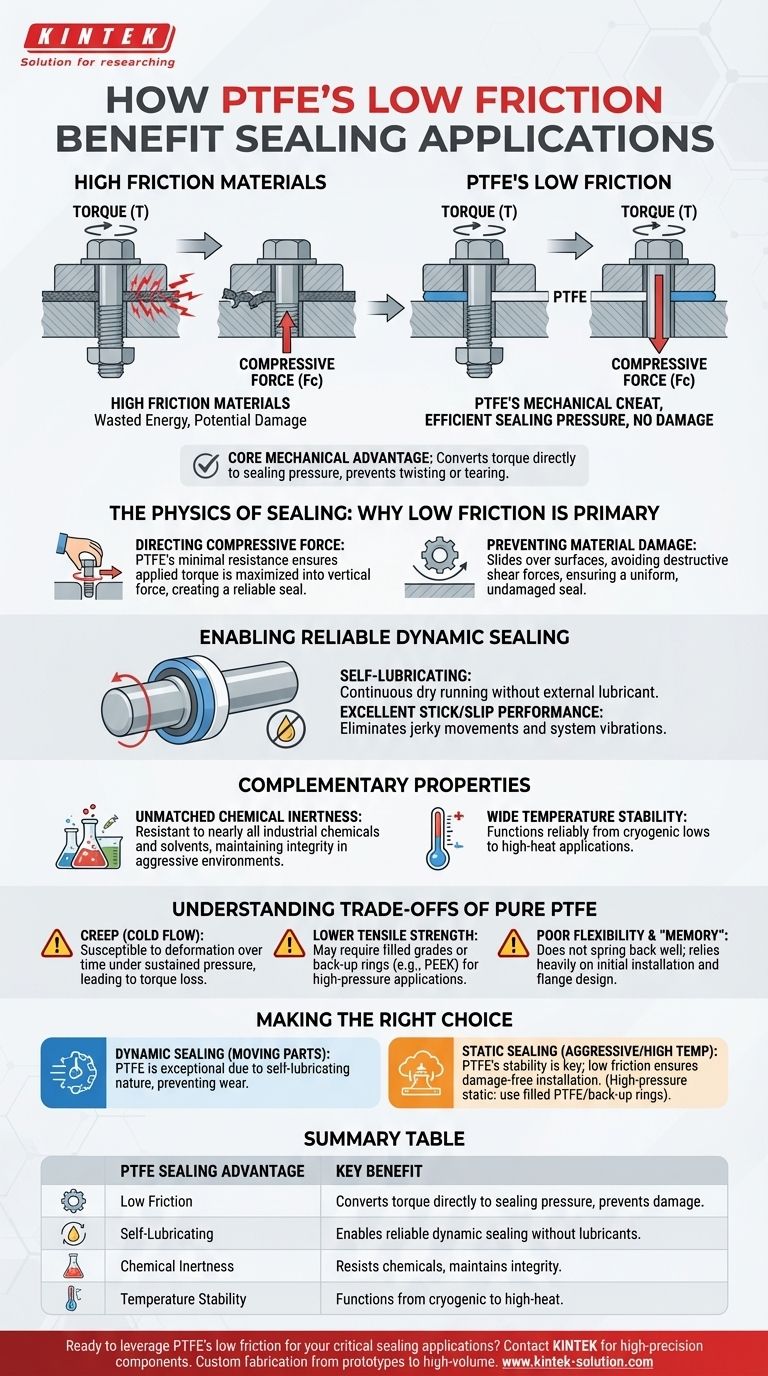

The low friction property of PTFE is critical for sealing applications because it ensures the force used to tighten a joint is converted directly into sealing pressure. Instead of being wasted overcoming friction, which can twist or tear a gasket, the energy is applied efficiently, creating a more reliable and undamaged seal. This characteristic is essential for both static joints and dynamic applications involving moving parts.

PTFE's low coefficient of friction is not merely a secondary benefit; it is a core mechanical advantage. It allows for predictable, low-stress installation and enables continuous, self-lubricated operation in dynamic seals where other materials would quickly fail.

The Physics of Sealing: Why Low Friction is a Primary Advantage

Understanding how a seal is formed reveals why friction can be a significant obstacle. The goal is to apply a uniform compressive force that closes any gaps between two surfaces.

Directing Compressive Force

When you tighten bolts on a flange, you are applying torque. With high-friction materials, a significant portion of this energy is lost simply trying to get the gasket material to slide into place.

PTFE’s extremely low friction, the lowest of any known solid, allows it to seat perfectly with minimal resistance. This ensures that nearly all the applied torque is converted into vertical, compressive force, which is the force that actually creates the seal.

Preventing Material Damage During Installation

High-friction gaskets can bind, bunch up, or tear as the flanges are tightened. This uneven distribution of material and stress creates weak points in the seal, leading to leaks.

Because PTFE slides over surfaces with almost no resistance, it is not subjected to these destructive shear forces. This prevents movement or tearing of the gasket surface, guaranteeing a uniform and undamaged seal upon installation.

Enabling Reliable Dynamic Sealing

In applications where parts move against the seal, such as a rotating shaft or a piston, friction is the primary cause of wear and failure.

PTFE's self-lubricating capabilities allow for continuous dry running without an external lubricant. This provides excellent stick/slip performance, eliminating the jerky movements that can compromise seal integrity and cause system vibrations.

Beyond Friction: Complementary Properties of PTFE

While its low friction is a key differentiator, PTFE’s value in sealing is amplified by its other unique properties, making it suitable for the most demanding industries.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This allows it to maintain its integrity and sealing performance in aggressive environments found in chemical processing or aerospace applications where other materials would degrade.

Wide Temperature Stability

PTFE functions reliably across an enormous temperature range, from cryogenic lows to high-heat applications. This stability ensures the seal remains effective and does not become brittle or lose its shape under extreme thermal cycling.

Understanding the Trade-offs of Pure PTFE

No material is perfect. To use PTFE effectively, it's crucial to understand its limitations, especially in its pure, unfilled form.

The Challenge of Creep (Cold Flow)

Pure PTFE is susceptible to creep, a phenomenon where the material slowly deforms over time under sustained pressure. This can lead to a loss of bolt torque and a reduction in sealing performance, particularly in static seals under high loads.

Lower Tensile Strength

Compared to metals or even some other polymers, PTFE has low tensile strength. In very high-pressure applications, a pure PTFE gasket may be forced out of the joint. This can be mitigated by using filled PTFE grades or incorporating stronger back-up rings (often made of PEEK) to provide structural support.

Poor Flexibility and "Memory"

Unlike rubber elastomers, PTFE has poor "memory"—it does not spring back to its original shape well after being compressed. This makes achieving a consistent and resilient seal more dependent on the initial installation and flange design.

Making the Right Choice for Your Application

Selecting the correct sealing material depends entirely on the operational demands of your system.

- If your primary focus is dynamic sealing (moving parts): PTFE is an exceptional choice, as its self-lubricating nature prevents wear and ensures smooth, continuous operation.

- If your primary focus is static sealing in aggressive chemical or high-temperature environments: PTFE’s chemical and thermal stability are its key advantages, while its low friction ensures a damage-free installation.

- If your primary focus is high-pressure static sealing: Pure PTFE is likely unsuitable due to creep. You should specify a filled PTFE composite or a seal design that includes rigid back-up rings for support.

Ultimately, leveraging PTFE's low friction property allows you to create more reliable, durable, and efficient seals in the applications where it is best suited.

Summary Table:

| PTFE Sealing Advantage | Key Benefit |

|---|---|

| Low Friction | Converts torque directly to sealing pressure, prevents damage during installation. |

| Self-Lubricating | Enables reliable dynamic sealing for moving parts without external lubricants. |

| Chemical Inertness | Resists nearly all industrial chemicals, maintaining integrity in harsh environments. |

| Temperature Stability | Functions reliably from cryogenic temperatures to high-heat applications. |

Ready to leverage PTFE's low friction for your critical sealing applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a seal that maximizes performance by converting installation force directly into reliable sealing pressure.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific needs. Don't let friction compromise your seal's integrity.

Contact KINTEK today to discuss your project and request a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications