For CNC machining purposes, the most relevant properties of PTFE (Polytetrafluoroethylene) are its low mechanical strength and stiffness, its extremely low coefficient of friction, and its high thermal expansion rate. These characteristics mean the material is soft, slippery, and highly sensitive to heat generated during cutting. Successfully machining PTFE depends entirely on managing these three factors to prevent deformation, melting, and dimensional inaccuracy.

The central challenge in machining PTFE is not its hardness, but its softness. Its tendency to deform under pressure and expand with heat requires a strategy focused on sharp tooling, low cutting forces, and minimal heat generation to achieve precision.

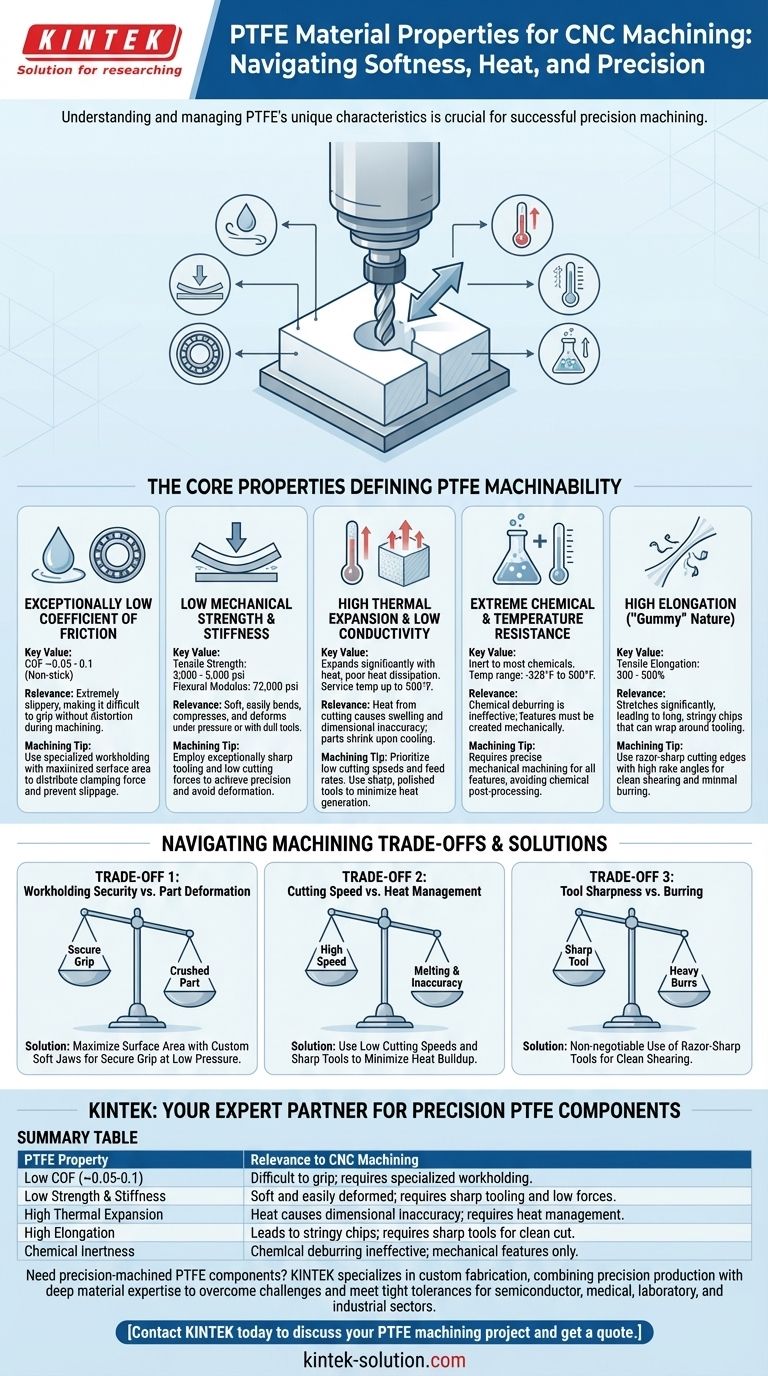

The Core Properties Defining PTFE Machinability

To understand how to approach PTFE, we must first examine the specific properties that directly influence the cutting process. These traits are fundamentally different from those of metals and even other common plastics.

Exceptionally Low Coefficient of Friction

PTFE is famously slippery, with a coefficient of friction around 0.05 to 0.1. This non-stick quality is a primary reason it's chosen for applications like bearings and bushings.

During machining, this property means the material offers little resistance to a cutting tool, but it also makes it difficult to grip securely without distortion.

Low Mechanical Strength and Stiffness

PTFE is a soft material. It has a low tensile strength (3,000 - 5,000 psi) and a very low flexural modulus (72,000 psi).

This means it will easily bend, compress, or deform under pressure. Aggressive clamping or dull tooling will push the material rather than cut it, leading to poor accuracy.

High Thermal Expansion and Low Conductivity

PTFE expands significantly when heated and does not dissipate heat well. Its upper service temperature is 500°F (260°C), but problems arise far below that.

Friction from the cutting process generates heat that gets trapped in the material, causing it to swell. This can throw dimensions off during machining, only for the part to shrink and be out of tolerance once it cools.

Extreme Chemical and Temperature Resistance

PTFE is virtually inert to most chemicals, including harsh acids, and performs reliably across a vast temperature range (-328°F to 500°F).

While this makes it invaluable for lab equipment and industrial seals, it also means standard chemical deburring or polishing methods are ineffective. All features must be created mechanically.

High Elongation

With a tensile elongation of 300 - 500%, PTFE can stretch significantly before breaking.

This "gummy" nature contributes to the formation of long, stringy chips that can wrap around tooling. It also reinforces the need for exceptionally sharp tools to achieve a clean shearing action.

Understanding the Trade-offs in Machining PTFE

The unique properties of PTFE create several challenges where the ideal approach isn't immediately obvious. Balancing competing factors is key.

Trade-off 1: Workholding Security vs. Part Deformation

Because PTFE is so slippery, you need to hold it securely. However, its softness means excessive clamping pressure will crush it, ruining the part before the first cut.

The solution is to maximize surface area to distribute clamping force. Use fixtures with wide contact areas, pie jaws on a lathe, or custom soft jaws that conform to the part's shape. This provides a secure grip with low pressure.

Trade-off 2: Cutting Speed vs. Heat Management

Attempting to machine PTFE at speeds used for aluminum will instantly cause frictional heat buildup, leading to melting, a poor surface finish, and dimensional instability.

You must prioritize quality over speed. Employ low cutting speeds and feed rates to minimize heat generation. Sharp, polished carbide tools also reduce friction, further aiding in heat control.

Trade-off 3: Tool Sharpness vs. Burring

A sharp tool is non-negotiable. A razor-sharp cutting edge with a high rake angle will shear the material cleanly.

A dull or incorrect tool will plow through the material, deforming it and creating heavy, difficult-to-remove burrs. Due to PTFE's softness and chemical resistance, deburring is a time-consuming manual process that should be avoided.

Making the Right Choice for Your Application

Your machining strategy should be dictated by the final requirements of the part.

- If your primary focus is high-precision components: Prioritize thermal stability by using very low cutting parameters, sharp tools, and potentially machining in stages to allow the part to cool.

- If your primary focus is creating low-friction surfaces: Use tools with highly polished flutes and a geometry designed for plastics to achieve the best possible surface finish directly from the machine.

- If your primary focus is food-grade or medical parts: Machine the part dry or with a compatible coolant (like pure water) to avoid chemical contamination, as PTFE's inertness is its key feature.

Ultimately, successfully machining PTFE comes from respecting its properties, not fighting them.

Summary Table:

| Key PTFE Property | Relevance to CNC Machining |

|---|---|

| Low Coefficient of Friction (~0.05-0.1) | Difficult to grip securely; requires specialized workholding to avoid slippage without deformation. |

| Low Mechanical Strength & Stiffness | Soft and easily deformed by clamping pressure or dull tools; requires sharp tooling and low cutting forces. |

| High Thermal Expansion & Low Conductivity | Heat from cutting causes swelling and dimensional inaccuracy; requires low speeds/feeds and sharp tools to manage heat. |

| High Elongation (300-500%) | Leads to stringy chips; requires sharp tools for a clean shear cut to minimize burring. |

| Chemical Inertness | Standard chemical deburring is ineffective; all features must be achieved mechanically during machining. |

Need precision-machined PTFE components?

Machining PTFE to exact specifications requires expert knowledge of its unique properties. KINTEK specializes in the custom fabrication of high-quality PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine precision production with deep material expertise to overcome the challenges of softness and heat sensitivity, delivering parts that meet your tightest tolerances. Whether you need prototypes or high-volume orders, we ensure success.

Contact KINTEK today to discuss your PTFE machining project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability