Under the right conditions, PTFE slide bearings can support significantly higher loads than many traditional bearing systems. They are specifically engineered for applications involving immense structural weight and slow, controlled movement, such as bridges and large buildings, often outperforming conventional roller or rocker arm supports in these high-pressure scenarios.

The critical distinction isn't just about maximum load, but the specific combination of high load and low speed. PTFE slide bearings excel in this exact domain, offering a simple, maintenance-free solution where traditional mechanical bearings can be overly complex or less effective.

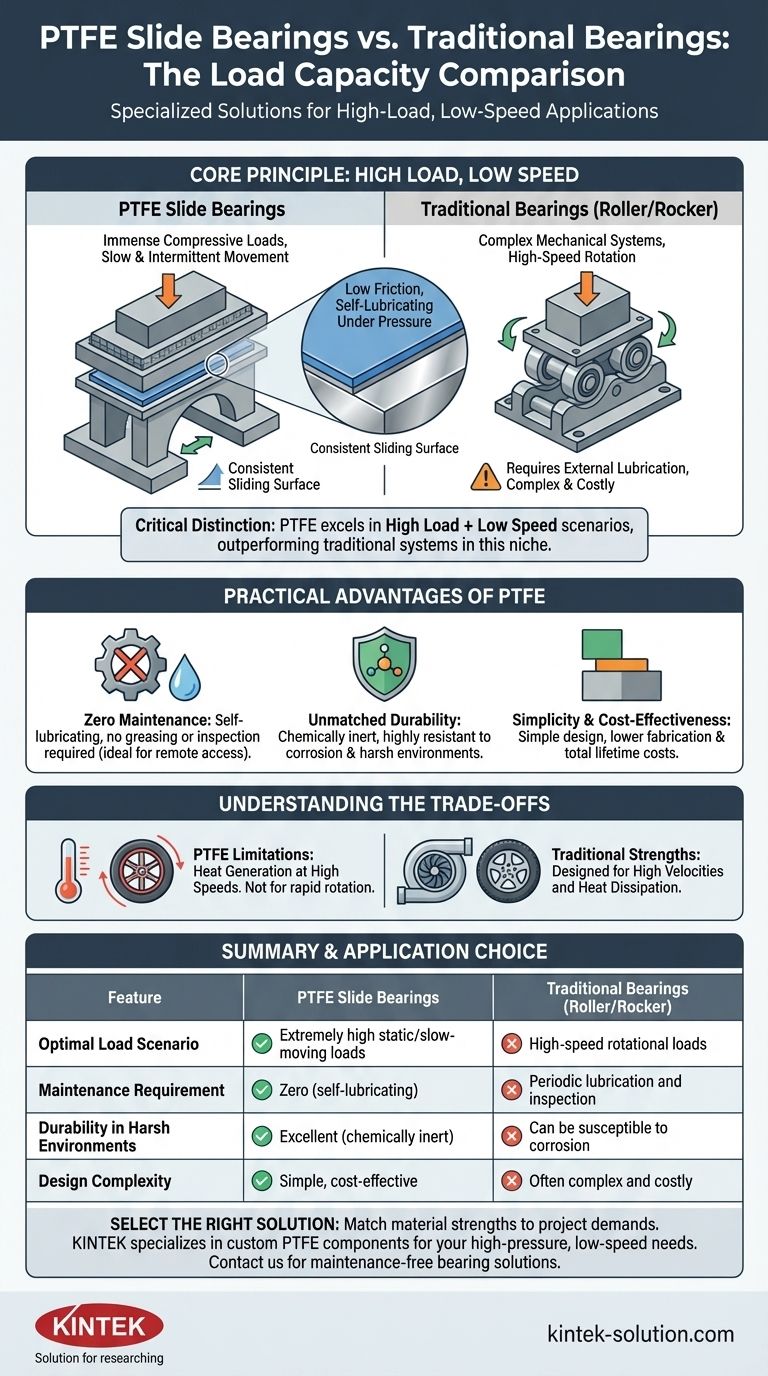

The Core Principle: High Load, Low Speed

The effectiveness of any bearing is defined by its operating environment. PTFE slide bearings are not a universal replacement for all bearing types; they are specialists designed for a very specific performance niche.

Defining the Performance Niche

PTFE slide bearings are optimized for applications where compressive loads are extremely high and movement is slow and intermittent. Think of the thermal expansion and contraction of a bridge, the settling of a skyscraper, or the positioning of a heavy industrial vessel.

In these cases, the bearing must accommodate immense pressure without failing, while allowing for slight, low-velocity adjustments.

How PTFE Handles Extreme Pressure

The material's unique properties are key to its performance. The low coefficient of friction of PTFE allows surfaces to slide against each other under immense pressure with minimal resistance.

Furthermore, its self-lubricating nature means no external lubrication is ever required. This process is most effective under high pressure, which ensures a consistent and reliable sliding surface over the bearing's entire lifespan.

The Advantage Over Traditional Supports

For massive structural loads, traditional solutions like mechanical rollers or rocker arms can be complex, costly, and require regular maintenance.

PTFE slide bearings offer a much simpler design. They consist of a sheet of PTFE bonded to a backing plate, which slides against a polished surface like stainless steel. This simplicity translates to easier fabrication, installation, and superior long-term reliability.

Beyond Load Capacity: The Practical Advantages

While their ability to handle high loads is paramount, the secondary benefits of PTFE bearings are what make them a definitive choice for many structural engineers and designers.

Maintenance-Free Operation

Because PTFE is self-lubricating, these bearings require zero maintenance. This is a decisive advantage in applications like bridges or pipelines where access is difficult and costly. Traditional metal bearings, in contrast, often require periodic greasing and inspection.

Unmatched Durability

PTFE is chemically inert, making it highly resistant to corrosion and chemical attack. This allows PTFE slide bearings to perform reliably for decades in harsh outdoor, marine, or industrial environments where metal components would degrade.

Simplicity and Cost-Effectiveness

The design of a PTFE slide bearing is fundamentally simple. This leads to lower fabrication and installation costs compared to complex roller or rocker assemblies. Their reliability and lack of maintenance also contribute to a lower total cost of ownership over the project's lifecycle.

Understanding the Trade-offs

No single solution is perfect for every problem. The primary limitation of PTFE slide bearings is the counterpart to their greatest strength: speed.

Heat Generation at High Speeds

PTFE is a polymer and does not dissipate heat as well as metal. High-speed, continuous movement would generate friction and heat that could compromise the bearing's integrity. For applications involving rapid rotation, such as in vehicle wheels or electric motors, traditional roller or ball bearings are the appropriate choice.

Comparing Friction Characteristics

While PTFE has a very low coefficient of friction, it remains constant across a range of conditions. In some high-tech machinery, other types of bearings might offer even lower friction, but they often come with much greater complexity and cost. For heavy structural loads, the reliable and constant friction of PTFE is ideal.

Making the Right Choice for Your Application

Selecting the correct bearing comes down to a clear-eyed assessment of your project's specific demands.

- If your primary focus is supporting immense, static or slow-moving structural loads (like a bridge, stadium, or heavy industrial equipment): PTFE slide bearings are often the superior choice due to their exceptional load capacity and maintenance-free durability.

- If your primary focus is managing high-speed rotational movement (like in machinery, turbines, or vehicles): Traditional roller or ball bearings are the correct technical solution, as they are designed to manage friction and heat at high velocities.

- If your primary focus is reliability in a corrosive or harsh environment: The chemical inertness of PTFE gives it a significant advantage over traditional metal-based bearing systems.

Ultimately, selecting the right bearing technology requires matching the material's inherent strengths to the specific load and speed demands of your project.

Summary Table:

| Feature | PTFE Slide Bearings | Traditional Bearings (Roller/Rocker) |

|---|---|---|

| Optimal Load Scenario | Extremely high static/slow-moving loads | High-speed rotational loads |

| Maintenance Requirement | Zero (self-lubricating) | Periodic lubrication and inspection |

| Durability in Harsh Environments | Excellent (chemically inert) | Can be susceptible to corrosion |

| Design Complexity | Simple, cost-effective | Often complex and costly |

Need a reliable, high-load bearing solution for your structural or industrial project? KINTEK specializes in manufacturing precision PTFE components, including custom slide bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a maintenance-free, durable bearing designed for your specific high-pressure, low-speed application. Contact our team today to discuss your project requirements and benefit from our custom fabrication services, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability