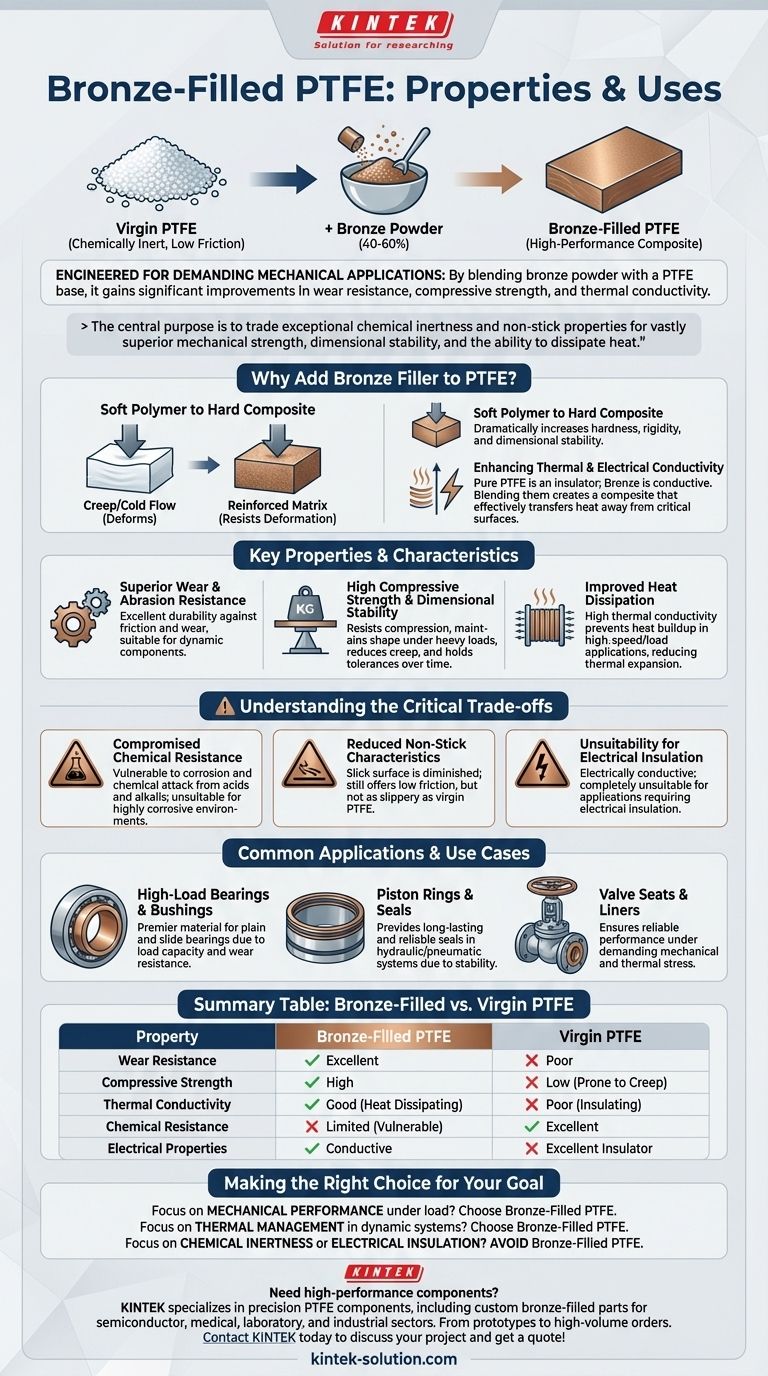

Bronze-filled PTFE is a high-performance composite material engineered to overcome the mechanical limitations of pure PTFE. By blending bronze powder (typically 40-60%) with a PTFE base, it gains significant improvements in wear resistance, compressive strength, and thermal conductivity, making it ideal for demanding mechanical applications.

The central purpose of adding bronze to PTFE is to trade its exceptional chemical inertness and non-stick properties for vastly superior mechanical strength, dimensional stability, and the ability to dissipate heat.

Why Add Bronze Filler to PTFE?

Virgin PTFE is known for its extreme chemical resistance and low friction, but it is mechanically soft. It can deform under load, a phenomenon known as "creep" or "cold flow." Adding a bronze filler fundamentally changes its nature.

From a Soft Polymer to a Hard Composite

Adding bronze particles creates a reinforced matrix. This dramatically increases the material's hardness, rigidity, and ability to resist deformation under pressure.

Enhancing Thermal and Electrical Conductivity

Pure PTFE is an excellent thermal and electrical insulator. Bronze is a conductor. Blending them creates a composite that can effectively transfer heat away from critical surfaces, a vital property in high-friction applications.

Key Properties and Characteristics

The addition of bronze provides a specific set of enhanced capabilities that define its primary uses in engineering.

Superior Wear and Abrasion Resistance

This is the most significant advantage. Bronze-filled PTFE has excellent durability against friction and wear, far surpassing that of unfilled PTFE, making it suitable for dynamic components.

High Compressive Strength and Dimensional Stability

The material resists compression and maintains its shape under heavy loads. This reduction in creep and cold flow ensures that components made from it hold their tolerances over time.

Improved Heat Dissipation

Its high thermal conductivity prevents heat buildup in high-speed and high-load applications, such as bearings. This reduces thermal expansion and maintains the component's integrity.

Understanding the Critical Trade-offs

These enhanced properties come at a cost. Understanding these compromises is essential for proper material selection.

Compromised Chemical Resistance

Bronze is not nearly as inert as PTFE. The composite is vulnerable to corrosion and chemical attack from acids and alkalis, making it unsuitable for the highly corrosive environments where virgin PTFE excels.

Reduced Non-Stick Characteristics

The slick, low-friction surface of pure PTFE is diminished by the addition of bronze particles. While it still offers a low coefficient of friction, it is not as slippery as the unfilled version.

Unsuitability for Electrical Insulation

Because bronze is conductive, the composite is also electrically conductive. This makes it completely unsuitable for applications requiring electrical insulation or isolation.

Common Applications and Use Cases

The unique balance of properties in bronze-filled PTFE makes it the ideal choice for several specific industrial applications.

High-Load Bearings and Bushings

Its ability to withstand heavy loads without deforming, combined with excellent wear resistance, makes it a premier material for plain bearings and slide bearings.

Piston Rings and Seals

In hydraulic and pneumatic systems, the material's dimensional stability and wear resistance provide a long-lasting and reliable seal for piston rings and other dynamic sealing components.

Valve Seats and Liners

For components in engines or industrial pipelines, its durability and thermal conductivity ensure reliable performance under demanding mechanical and thermal stress.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary demands of your application.

- If your primary focus is mechanical performance under load: Choose bronze-filled PTFE for its superior wear resistance, high compressive strength, and dimensional stability.

- If your primary focus is thermal management in a dynamic system: The high thermal conductivity of bronze-filled PTFE makes it ideal for dissipating frictional heat.

- If your primary focus is chemical inertness or electrical insulation: You must avoid bronze-filled PTFE and select virgin PTFE or a PTFE with a different filler (like glass or carbon).

Ultimately, choosing bronze-filled PTFE is an engineering decision to prioritize mechanical robustness and thermal performance where extreme chemical resistance is not required.

Summary Table:

| Property | Bronze-Filled PTFE | Virgin PTFE |

|---|---|---|

| Wear Resistance | Excellent | Poor |

| Compressive Strength | High | Low (Prone to Creep) |

| Thermal Conductivity | Good (Heat Dissipating) | Poor (Insulating) |

| Chemical Resistance | Limited (Vulnerable to Acids/Alkalis) | Excellent |

| Electrical Properties | Conductive | Excellent Insulator |

Need high-performance components that can handle heavy loads and dissipate heat?

Bronze-filled PTFE is engineered for demanding applications like bearings, seals, and piston rings. At KINTEK, we specialize in manufacturing precision PTFE components, including custom bronze-filled parts for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for durability and performance.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support