Looking forward, the future of PTFE seal technology is not about a single breakthrough but a convergence of three key areas: the development of advanced composite materials, the adoption of precision manufacturing techniques like 3D printing, and an overarching drive for higher performance and sustainability. These trends are moving PTFE seals from a general-purpose component to a highly engineered solution for specific, demanding applications.

The core trend in PTFE seal technology is the shift from using a single, versatile material to creating highly specialized solutions. This is achieved by precisely modifying the material's composition and manufacturing process to meet the extreme demands of industries like aerospace, semiconductors, and medicine.

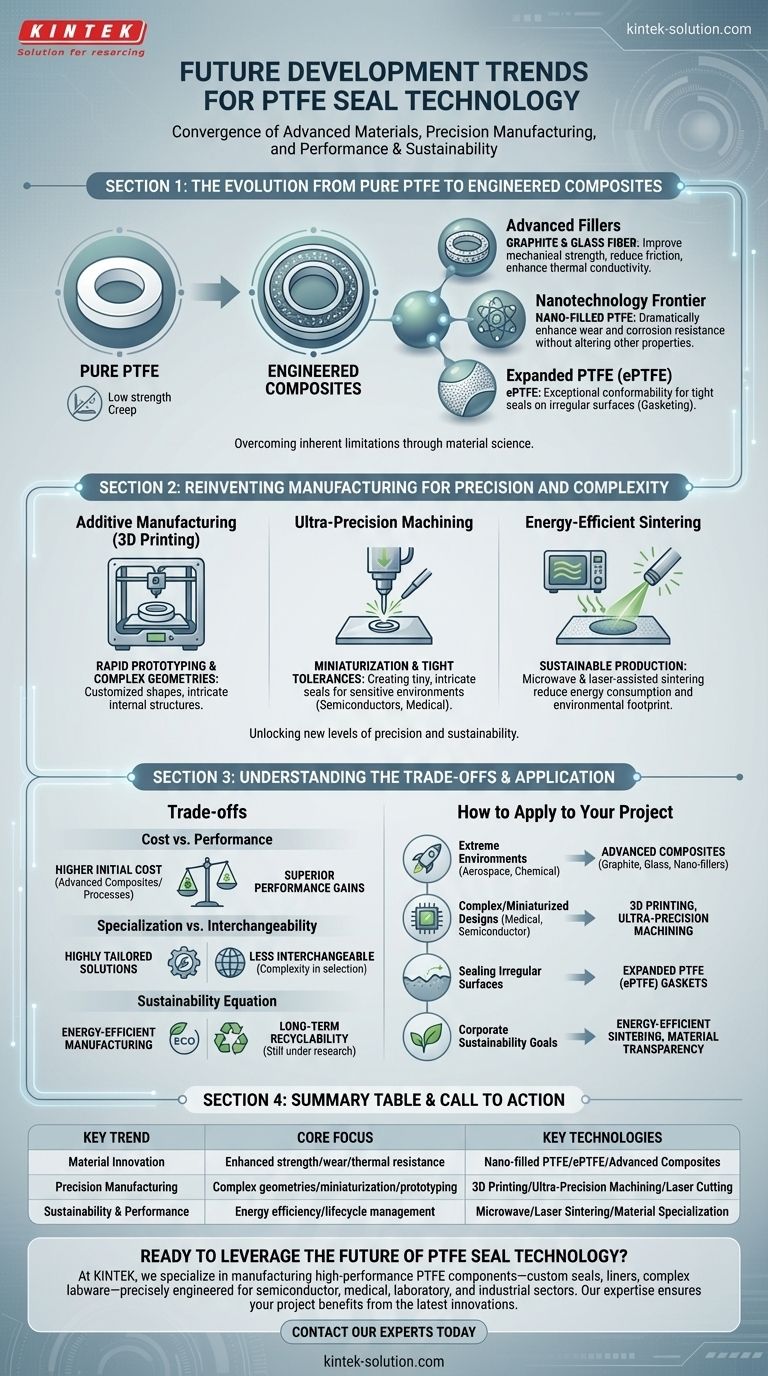

The Evolution from Pure PTFE to Engineered Composites

The primary driver for material innovation is overcoming the inherent limitations of pure PTFE, such as its relative softness and susceptibility to creep under load. The future lies in enhancing its properties with specialized fillers.

Overcoming Inherent Weaknesses

Pure PTFE is known for its incredible chemical resistance and low friction, but it lacks mechanical strength and wear resistance. Composite materials address this by integrating other materials to create a superior blend of properties.

The Role of Traditional Fillers

Fillers like graphite and glass fiber are well-established for improving the performance of PTFE. Graphite enhances thermal conductivity and reduces friction, while glass fiber significantly increases mechanical strength and rigidity.

The Nanotechnology Frontier

The next evolution is nano-filled PTFE. By incorporating materials at the nanoscale, engineers can dramatically enhance wear resistance, improve thermal conductivity, and boost corrosion resistance without significantly altering the seal's other desirable properties.

The Rise of Expanded PTFE (ePTFE)

Expanded PTFE (ePTFE) is created by stretching PTFE, resulting in a microporous structure. This gives it exceptional conformability, allowing it to create a tight seal even on irregular or damaged surfaces, making it ideal for gasketing.

Reinventing Manufacturing for Precision and Complexity

How a seal is made is becoming just as important as what it is made of. Advanced manufacturing is unlocking new levels of precision and enabling geometries that were previously impossible.

Additive Manufacturing (3D Printing)

The ability to 3D print modified PTFE is a game-changer. It allows for the rapid prototyping and production of seals with highly complex internal structures and customized shapes, perfectly tailored to a specific application.

Ultra-Precision Machining and Cutting

For industries like semiconductors and medical devices, miniaturization is key. Ultra-precision machining and laser cutting enable the creation of tiny, intricate seals with extremely tight tolerances, ensuring purity and performance in sensitive environments.

Energy-Efficient Sintering

The manufacturing process itself is becoming more sustainable. New methods like microwave and laser-assisted sintering consume less energy to cure the PTFE material, reducing the environmental footprint and potentially lowering production costs.

Understanding the Trade-offs

While these advancements promise superior performance, they introduce new considerations that require a balanced approach. Adopting new technology is never without trade-offs.

Cost vs. Performance

Advanced composites and precision manufacturing processes are inherently more expensive than traditional methods for producing pure PTFE seals. The performance gains must be carefully weighed against the increased initial cost.

The Challenge of Specialization

As seals become more specialized, they become less interchangeable. A nano-filled composite designed for a high-wear aerospace application may not be the right choice for a food-grade processing plant, increasing the complexity of material selection and inventory management.

The Sustainability Equation

While manufacturing is becoming more energy-efficient, PTFE remains a fluoropolymer. The long-term environmental impact and end-of-life recyclability of these advanced composites are still areas of active research and consideration for environmentally-conscious industries.

How to Apply This to Your Project

Understanding these trends allows you to make more informed, forward-looking decisions for your specific needs.

- If your primary focus is extreme environments (aerospace, chemical): You should investigate advanced composites with graphite, glass, or nano-fillers to gain the required mechanical strength and thermal stability.

- If your primary focus is complex or miniaturized designs (medical, semiconductor): You should prioritize suppliers utilizing 3D printing or ultra-precision machining to achieve the necessary geometry and tolerances.

- If your primary focus is sealing irregular surfaces: Expanded PTFE (ePTFE) gaskets offer superior conformability and should be your leading choice.

- If your primary focus is meeting corporate sustainability goals: You should inquire about manufacturers using energy-efficient sintering methods and seek transparency on material lifecycle.

By aligning your requirements with these emerging technologies, you can ensure your designs are not just effective today but are built on the most capable solutions of tomorrow.

Summary Table:

| Key Trend | Core Focus | Key Technologies |

|---|---|---|

| Material Innovation | Enhanced strength, wear & thermal resistance | Nano-filled PTFE, Expanded PTFE (ePTFE), Advanced Composites |

| Precision Manufacturing | Complex geometries, miniaturization, rapid prototyping | 3D Printing, Ultra-Precision Machining, Laser Cutting |

| Sustainability & Performance | Energy efficiency, lifecycle management | Microwave/Laser Sintering, Material Specialization |

Ready to leverage the future of PTFE seal technology for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from custom seals and liners to complex labware—precisely engineered for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in advanced composites and precision fabrication (including prototyping and high-volume orders) ensures your project benefits from the latest material and manufacturing innovations.

Contact our experts today to discuss how our tailored PTFE solutions can enhance your product's performance, durability, and sustainability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What post-machining processes can improve PTFE surface finishes? Achieve a Flawless Finish for Your Components

- How does PCTFE compare to PTFE for cryogenic applications? Choose the Right Material for Extreme Cold

- Which substances is PTFE not chemically resistive to? Avoid These Extreme Conditions

- Why is the manufacturing cost of PTFE processing machines high? The Engineering Behind High-Performance Polymer Processing

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How can PTFE's properties be enhanced? Boost Performance with Filled PTFE Composites

- What are the primary uses of Teflon encapsulated O-Rings? Seal Against Aggressive Chemicals & High Temperatures

- Why are PTFE Bellows suitable for electroplating processes? Master Harsh Chemical & Thermal Environments