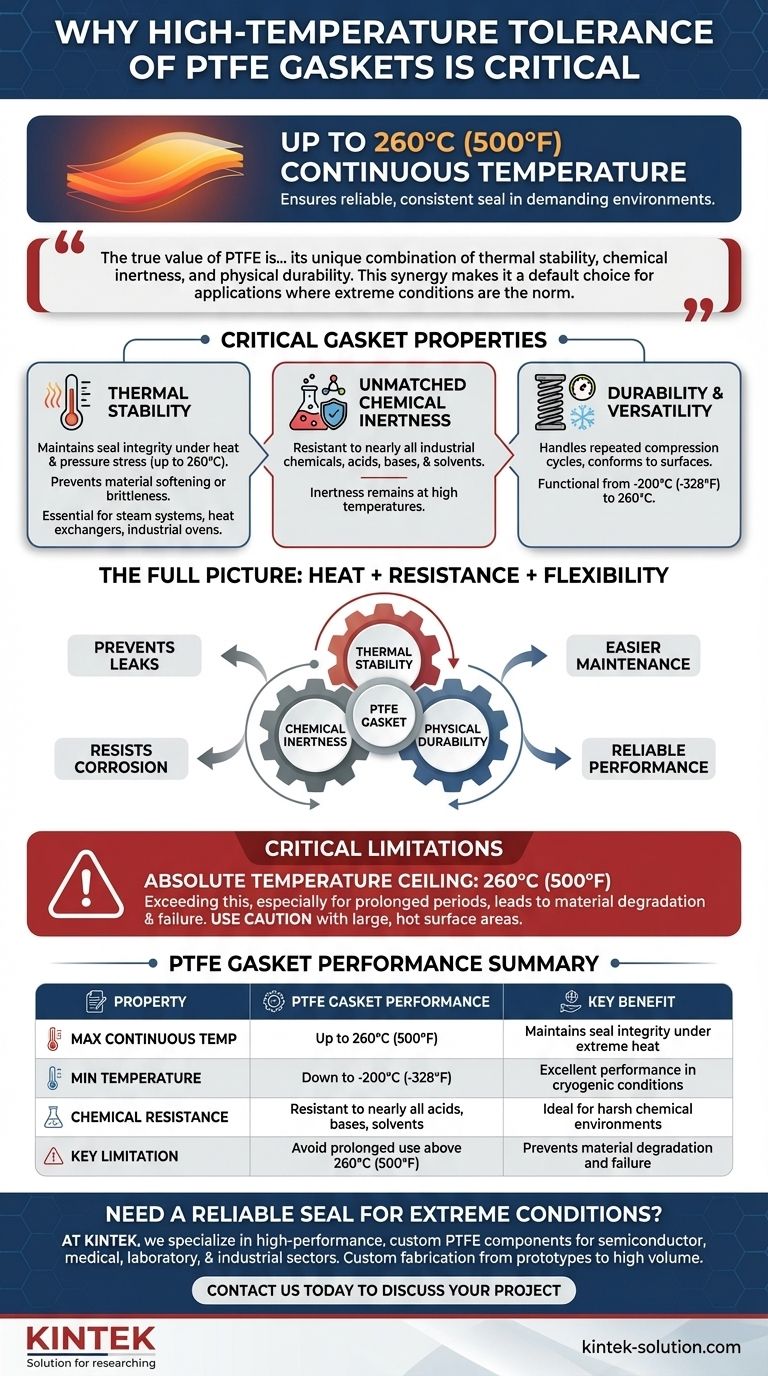

In short, the high-temperature tolerance of Polytetrafluoroethylene (PTFE) gaskets is critical because it ensures a reliable and consistent seal in demanding industrial environments. This material maintains its physical integrity and sealing properties at continuous temperatures up to 260°C (500°F), preventing leaks in systems where other materials would quickly degrade and fail.

The true value of PTFE is not just its ability to withstand heat, but its unique combination of thermal stability, chemical inertness, and physical durability. This synergy makes it a default choice for applications where extreme conditions are the norm.

Why Thermal Stability is a Critical Gasket Property

A gasket's primary function is to create a seal between two surfaces, preventing leakage. In environments with high heat or significant temperature fluctuations, this simple task becomes a major engineering challenge.

Maintaining Seal Integrity Under Stress

At high temperatures, materials expand. This thermal expansion, along with pressure, puts immense stress on a gasket.

PTFE's ability to remain stable up to 260°C (500°F) means it won't lose its shape or sealing force, ensuring a tight connection is maintained even as the surrounding components heat up.

Preventing Material Degradation

Many common gasket materials, like certain elastomers, will soften, melt, or become brittle when exposed to high heat.

PTFE, by contrast, resists this thermal breakdown. This property is essential in applications like steam systems, heat exchangers, and industrial ovens where consistent, reliable performance is non-negotiable.

Enabling Versatility Across Applications

The material's impressive thermal range is not limited to heat. PTFE performs equally well in cryogenic conditions, remaining functional down to -200°C (-328°F).

This exceptionally wide operating window makes it one of the most versatile sealing materials available for processes involving extreme temperature cycles.

The Full Picture: More Than Just Heat Resistance

While its temperature tolerance is a headline feature, it's the combination with PTFE's other inherent properties that makes it so valuable in industrial settings.

Unmatched Chemical Inertness

High temperatures often accelerate chemical reactions. A material that is stable at room temperature might corrode quickly when heated.

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, and solvents. This inertness does not diminish at high temperatures, making it ideal for sealing harsh chemicals in heated process lines.

Non-Stick Surface Properties

In systems like heat exchangers, material buildup (fouling) can reduce efficiency. PTFE's non-stick surface helps prevent this.

This quality ensures easier cleaning and maintenance and helps maintain the operational efficiency of the equipment it's installed in.

Durability and Flexibility

PTFE is a durable material that can handle repeated compression cycles. It is also flexible enough to conform to imperfect or uneven flange surfaces.

This ensures a more reliable seal across a wider variety of real-world conditions, preventing leaks that might otherwise occur due to minor surface flaws.

Understanding the Critical Limitations

No material is perfect, and objectivity requires acknowledging a product's operational boundaries. Understanding PTFE's limits is key to its successful application.

The Absolute Temperature Ceiling

The stated limit of 260°C (500°F) is a critical boundary. Exceeding this temperature, especially for prolonged periods, can lead to material degradation.

Risk of Breakdown

When exposed to temperatures beyond its maximum rating, PTFE can begin to break down.

It is particularly important to use PTFE cautiously in applications involving large, hot surface areas, as prolonged exposure can cause the material to fail and compromise the seal.

How to Apply This to Your Project

Your choice of gasket material should be directly aligned with the specific demands of your system.

- If your primary focus is consistent high-heat operations (up to 260°C): PTFE provides a reliable seal where many other elastomers and sealing materials would fail.

- If your application involves both extreme cold and heat: PTFE's exceptionally wide operating temperature range offers unparalleled versatility and simplifies material specification.

- If you need to seal aggressive chemicals at elevated temperatures: The combination of PTFE's thermal stability and its near-universal chemical inertness is its most powerful advantage.

Ultimately, understanding both the exceptional capabilities and the absolute limits of PTFE's temperature tolerance is key to engineering a safe and reliable system.

Summary Table:

| Property | PTFE Gasket Performance | Key Benefit |

|---|---|---|

| Max Continuous Temperature | Up to 260°C (500°F) | Maintains seal integrity under extreme heat |

| Min Temperature | Down to -200°C (-328°F) | Excellent performance in cryogenic conditions |

| Chemical Resistance | Resistant to nearly all acids, bases, and solvents | Ideal for harsh chemical environments |

| Key Limitation | Avoid prolonged use above 260°C (500°F) | Prevents material degradation and failure |

Need a reliable seal for extreme temperatures and harsh chemicals?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, gaskets, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your equipment operates safely and efficiently, even in the most demanding conditions.

We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications