The primary challenges in machining Teflon (PTFE) stem directly from its most valued properties: its extreme softness, low friction, and sensitivity to heat. These characteristics cause the material to deform under pressure, resist clean cutting, and expand unpredictably, making it difficult to hold tight tolerances and avoid burrs.

Teflon's greatest strengths in application—its slipperiness and softness—are the very properties that create the greatest challenges during fabrication. Success requires treating it less like a rigid plastic and more like a dense, thermally sensitive wax that must be shaved with precision rather than cut with force.

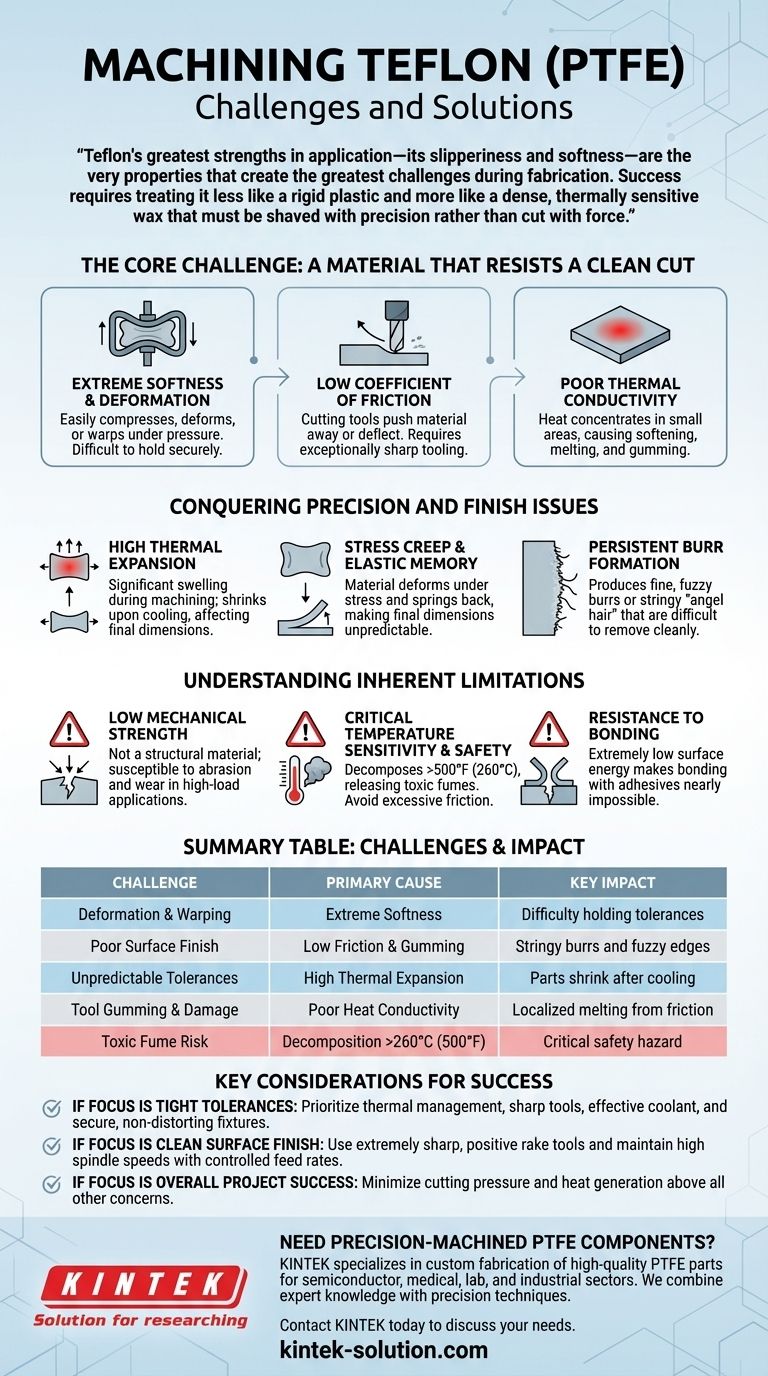

The Core Challenge: A Material That Resists a Clean Cut

The fundamental difficulty in machining PTFE is that it behaves in ways that are counter-intuitive to standard cutting practices developed for metals and harder plastics.

Extreme Softness and Deformation

PTFE is incredibly soft and lacks rigidity. Any excessive pressure from clamping fixtures or the cutting tool itself can easily cause the material to compress, deform, or warp. This makes simply holding the workpiece securely without damaging it the first major hurdle.

Low Coefficient of Friction

The "slipperiness" that makes PTFE an excellent non-stick surface means that a cutting tool can easily push the material away or cause it to deflect rather than shearing it cleanly. This phenomenon requires exceptionally sharp tooling to initiate and maintain a proper cut.

Poor Thermal Conductivity

Unlike metals that dissipate heat quickly, PTFE is an excellent thermal insulator. All the heat generated by the friction of the cutting tool remains concentrated in a very small area. This localized heating can cause the material to soften, melt, or gum up the tool, ruining the cut and the part.

Conquering Precision and Finish Issues

The core material properties directly lead to common defects that machinists must actively work to prevent.

High Thermal Expansion

Because PTFE traps heat and has a high coefficient of thermal expansion, it will swell significantly during the machining process. As the finished part cools to room temperature, it shrinks, often pulling dimensions out of the specified tolerance.

Stress Creep and Elastic Memory

The material has a tendency to "creep," or slowly deform over time when under stress. During machining, the part can deform under tool pressure and then partially spring back after the tool passes, making final dimensions unpredictable and difficult to control.

Persistent Burr Formation

PTFE does not form clean chips like metal. Due to its softness and low melting point, it tends to produce a fine, fuzzy burr or a stringy "angel hair" swarf. These burrs can be very difficult to remove cleanly without damaging the part's surface.

Understanding the Inherent Limitations of PTFE

Beyond the direct machining challenges, it is critical to acknowledge the material's built-in trade-offs, which influence both the fabrication process and the final application.

Low Mechanical Strength

PTFE is not a structural material. It has low tensile strength and is susceptible to abrasion and wear in high-load applications. Designs must account for this inherent softness.

Critical Temperature Sensitivity and Safety

Heating PTFE above 500°F (260°C) causes it to decompose, releasing highly toxic and corrosive fumes. This is a critical safety consideration, as excessive friction from dull tools or aggressive cutting can easily generate this level of heat.

Resistance to Bonding

PTFE has one of the lowest surface energies of any solid, making it nearly impossible to bond with adhesives. This property must be considered during the design phase if assembly is required.

Key Considerations for a Successful Outcome

To machine Teflon effectively, you must adapt your strategy to accommodate the material's unique behavior. Your approach should be guided by your primary objective.

- If your primary focus is achieving tight tolerances: You must prioritize thermal management with sharp tools, effective coolant, and fixtures that secure the part without causing distortion.

- If your primary focus is a clean surface finish: The solution is using extremely sharp, positive rake cutting tools and maintaining high spindle speeds with controlled, lighter feed rates to "shave" the material.

- If your primary focus is overall project success: Treat PTFE as its own class of material, focusing on minimizing cutting pressure and heat generation above all other concerns.

By respecting its unique properties instead of fighting them, you can achieve precise and reliable results when machining Teflon.

Summary Table:

| Challenge | Primary Cause | Key Impact |

|---|---|---|

| Deformation & Warping | Extreme Softness | Difficulty holding tolerances |

| Poor Surface Finish | Low Friction & Gumming | Stringy burrs and fuzzy edges |

| Unpredictable Tolerances | High Thermal Expansion | Parts shrink after cooling |

| Tool Gumming & Damage | Poor Heat Conductivity | Localized melting from friction |

| Toxic Fume Risk | Decomposition >260°C (500°F) | Critical safety hazard |

Need Precision-Machined PTFE Components?

Don't let the challenges of machining Teflon compromise your project. KINTEK specializes in the custom fabrication of high-quality PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We combine expert knowledge of PTFE's unique properties with precision production techniques to deliver parts that meet your tightest tolerances and finish requirements, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do PTFE bearing pads contribute to structural safety and efficiency? Enhance Structural Integrity with Low-Friction Support

- Why is the non-stick surface of PTFE bushings beneficial? For Contamination-Free, Low-Maintenance Performance

- In which components of a mechanical seal is PTFE commonly used? Solve Sealing Challenges with Chemical Resistance

- What shapes and forms are PTFE washers available in? From Standard Circles to Custom Profiles

- In which automotive applications are PTFE rubber seals used? Essential for High-Performance and EV Systems

- What are the main industries that utilize PTFE lined valves? Ensure Safety and Purity in Critical Processes

- Why are Filled PTFE gaskets used in high-pressure settings? Enhanced Strength for Demanding Seals

- What makes PTFE seats suitable for demanding environments in butterfly valves? Unlock Chemical & Thermal Resilience