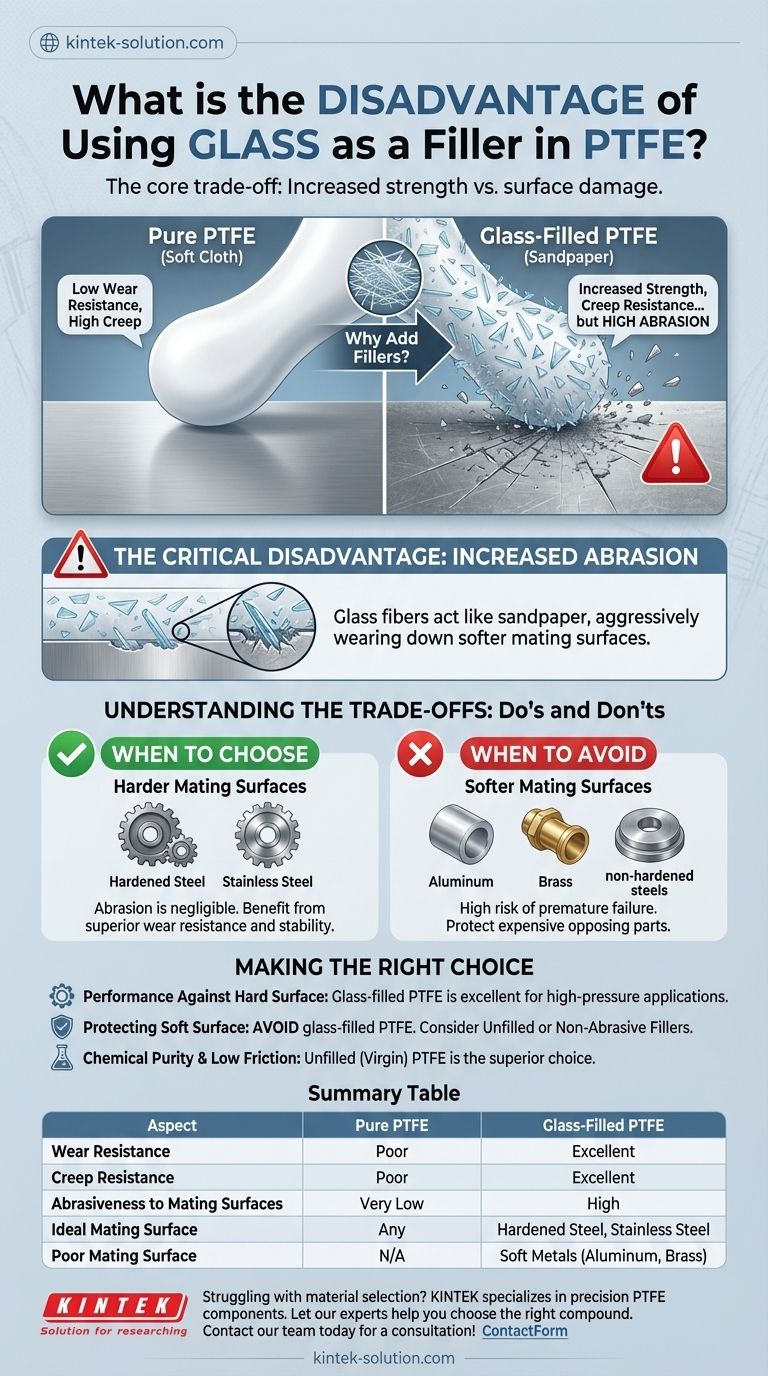

The single biggest disadvantage of using glass as a filler in Polytetrafluoroethylene (PTFE) is its abrasiveness. While adding glass fibers significantly improves the mechanical properties of PTFE, it also transforms the material into one that can actively wear down the surfaces it comes into contact with, especially if those surfaces are made of softer metals.

The core trade-off is simple: glass-filled PTFE gains significant strength, wear resistance, and resistance to deformation, but it achieves this at the cost of being abrasive to its mating surface. This makes material selection for the entire assembly a critical consideration.

Why Add Fillers to PTFE in the First Place?

Fillers are added to a base polymer like PTFE to enhance specific properties that the pure material lacks. Pure PTFE is an excellent material in many ways, but it has key mechanical weaknesses.

Addressing Pure PTFE's Weaknesses

Unfilled, or "virgin," PTFE is exceptionally soft. This results in poor wear resistance and high creep, which is the tendency of a material to deform permanently under a constant load.

In practical terms, a part made from pure PTFE might flow or change shape over time when used in load-bearing applications, leading to failure.

The Role of Glass Fibers

Glass fibers are a common filler used to directly combat these weaknesses.

Adding glass significantly increases PTFE's compressive strength and rigidity. This makes the material far more resistant to creep and general wear, allowing it to be used in higher-pressure and more demanding mechanical applications.

The Critical Disadvantage: Increased Abrasion

The solution to PTFE's softness is also the source of its primary disadvantage. The hard glass fibers that provide structural reinforcement are inherently abrasive.

What "Abrasive" Means in Practice

Imagine rubbing a soft cloth against a metal surface versus rubbing fine-grit sandpaper. Pure PTFE is the soft cloth, while glass-filled PTFE acts more like the sandpaper.

The microscopic glass fibers dispersed within the PTFE can cut into and remove material from the opposing mating surface during movement.

The Impact on Mating Surfaces

This abrasive quality is a major problem when the glass-filled PTFE component is paired with a surface made from a softer material.

Using glass-filled PTFE against materials like aluminum, brass, or non-hardened steels can cause premature and sometimes catastrophic wear on those components. The PTFE part may survive, but it will do so at the expense of the more critical, and often more expensive, part it runs against.

Understanding the Trade-offs

Choosing a material is never about finding a perfect solution; it's about accepting the right set of compromises for your specific goal.

When to Choose Glass-Filled PTFE

Glass-filled PTFE is an excellent choice for applications where the mating surface is harder than the filler.

This includes surfaces made of hardened steel, stainless steel, or other hard-coated metals. In these cases, the abrasiveness is negligible, and you benefit fully from the material's superior wear resistance and dimensional stability.

When to Avoid Glass-Filled PTFE

You must avoid glass-filled PTFE whenever the mating surface is a softer metal or plastic.

The risk of damaging the opposing component is too high. The cost of replacing a worn-out shaft or housing far outweighs the benefits of using a glass-filled seal or bearing in that scenario.

Making the Right Choice for Your Application

Your decision must be based on the properties of the entire mechanical system, not just the PTFE component in isolation.

- If your primary focus is performance against a hard surface: Glass-filled PTFE is an excellent choice for its superior wear and creep resistance in high-pressure applications.

- If your primary focus is protecting a soft mating surface: You must avoid glass-filled PTFE and instead consider unfilled PTFE or PTFE with a non-abrasive filler.

- If your primary focus is chemical purity and low friction with minimal load: Unfilled (virgin) PTFE remains the superior choice.

Ultimately, understanding the abrasive nature of glass filler is the key to using this powerful composite material effectively and preventing unintended damage to your equipment.

Summary Table:

| Aspect | Pure PTFE | Glass-Filled PTFE |

|---|---|---|

| Wear Resistance | Poor | Excellent |

| Creep Resistance | Poor | Excellent |

| Abrasiveness to Mating Surfaces | Very Low | High |

| Ideal Mating Surface | Any | Hardened Steel, Stainless Steel |

| Poor Mating Surface | N/A | Soft Metals (Aluminum, Brass) |

Struggling with material selection for your PTFE components? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, and industrial sectors. We understand the critical trade-offs between wear resistance and surface abrasion. Let our experts help you select or custom-fabricate the right PTFE compound—from prototypes to high-volume orders—to ensure optimal performance and protect your equipment. Contact our team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications