In short, PTFE oil seals are defined by their exceptional resistance to extreme conditions. They operate effectively across a vast temperature range, from cryogenic lows to engine-level highs, while remaining inert to nearly all industrial chemicals and solvents. This resilience, combined with an extremely low coefficient of friction, allows them to perform in applications where traditional rubber seals would quickly fail.

PTFE seals are not a universal replacement for standard elastomer seals, but rather a specialized solution for high-performance challenges. Their value is realized in environments involving extreme temperatures, aggressive media, high rotational speeds, or where dry-running capability is a necessity.

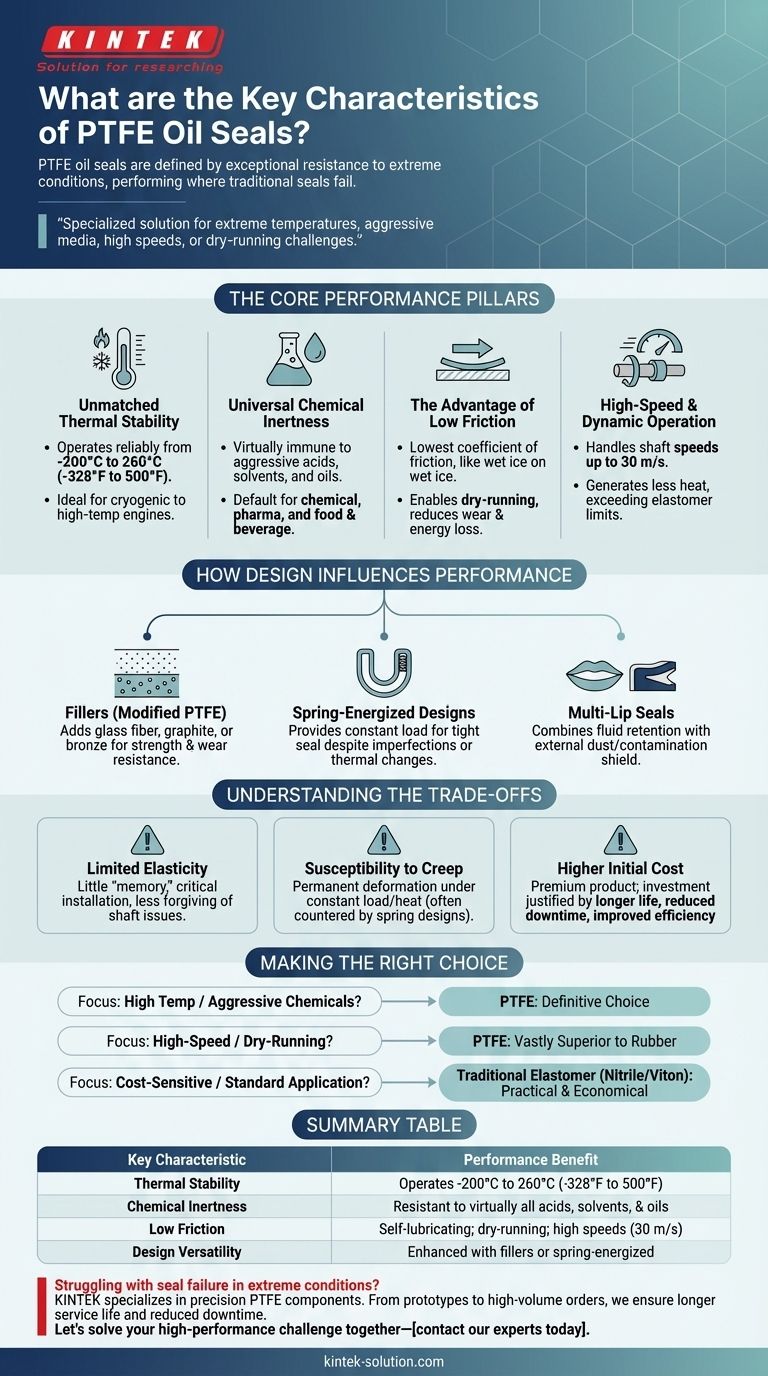

The Core Performance Pillars of PTFE Seals

To understand if a PTFE seal is right for your application, you must grasp the fundamental properties that set it apart from conventional materials like nitrile or viton rubber.

Unmatched Thermal Stability

PTFE operates reliably across an exceptionally wide temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F). This allows it to be used in everything from cryogenic equipment to high-performance engines, turbochargers, and industrial transmissions where heat buildup is significant.

Universal Chemical Inertness

The material is virtually immune to degradation from aggressive chemicals, including most acids, solvents, oils, and process fluids. This makes PTFE the default choice for sealing applications in the chemical processing, pharmaceutical, and food and beverage industries where media compatibility is non-negotiable.

The Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property reduces rotational drag, minimizes energy loss, and drastically cuts down on wear. Crucially, it also enables the seal to function in dry-running or minimally lubricated conditions.

High-Speed and Dynamic Operation

The low friction characteristic directly translates to superior performance in high-speed applications. By generating less frictional heat, PTFE seals can handle shaft speeds of up to 30 m/s, far exceeding the limits of most elastomer seals which would overheat and fail.

How Design Influences Performance

Not all PTFE seals are created equal. The base material is often enhanced through specific design choices to meet different operational demands.

The Role of Fillers (Modified PTFE)

While pure PTFE has excellent chemical and thermal properties, it can be relatively soft. To improve mechanical strength, rigidity, and wear resistance, fillers like glass fiber, graphite, or bronze are added. This makes the seal more durable under high pressure and load.

Spring-Energized Designs

A common design features a stainless steel spring embedded within the seal's U-cup channel. This spring provides a constant, uniform load on the sealing lip, ensuring a tight seal even with minor shaft imperfections, thermal expansion, or wear over time.

Multi-Lip Seals for Contamination Control

For dirty or dusty environments, multi-lip designs are employed. These typically combine a primary PTFE sealing lip to contain the fluid with a secondary, more flexible rubber or polyurethane lip to act as an external dust shield, protecting the primary seal.

Understanding the Trade-offs

While powerful, PTFE is not without its limitations. Objectivity requires acknowledging where it may not be the optimal choice.

Limited Elasticity

Unlike rubber, PTFE is a plastic and has very little "elastic memory." It does not rebound to its original shape as readily after being deformed. This makes installation more critical and means the seal is less forgiving of poor surface finishes or out-of-round shafts.

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, PTFE can slowly and permanently deform—a phenomenon known as creep. While spring-energized designs are specifically made to counteract this, it remains an inherent material property to consider in static, high-load applications.

Higher Initial Cost

PTFE seals are a premium product and are more expensive than their standard nitrile counterparts. The investment must be justified by a clear operational need for their advanced properties, with the return coming from longer service life, reduced downtime, and improved system efficiency.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision. Use the following guide to align your choice with your primary operational goal.

- If your primary focus is high temperatures or aggressive chemicals: PTFE is the definitive choice where elastomers would rapidly degrade or fail.

- If your primary focus is high-speed rotation or dry-running capability: The low-friction properties of PTFE prevent heat buildup and wear, making it vastly superior to rubber.

- If your primary focus is a cost-sensitive, standard industrial application: A traditional elastomer seal (like Nitrile or Viton) is often the more practical and economical solution.

Ultimately, understanding these core principles allows you to select a sealing solution based not on habit, but on the specific performance demands of your system.

Summary Table:

| Key Characteristic | Performance Benefit |

|---|---|

| Thermal Stability | Operates from -200°C to 260°C (-328°F to 500°F) |

| Chemical Inertness | Resistant to virtually all acids, solvents, and oils |

| Low Friction | Self-lubricating; enables dry-running and high speeds (up to 30 m/s) |

| Design Versatility | Enhanced with fillers or spring-energized for specific demands |

Struggling with seal failure in extreme conditions? KINTEK specializes in precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution that delivers longer service life, reduces downtime, and boosts system efficiency. Let's solve your high-performance challenge together—contact our experts today for a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining