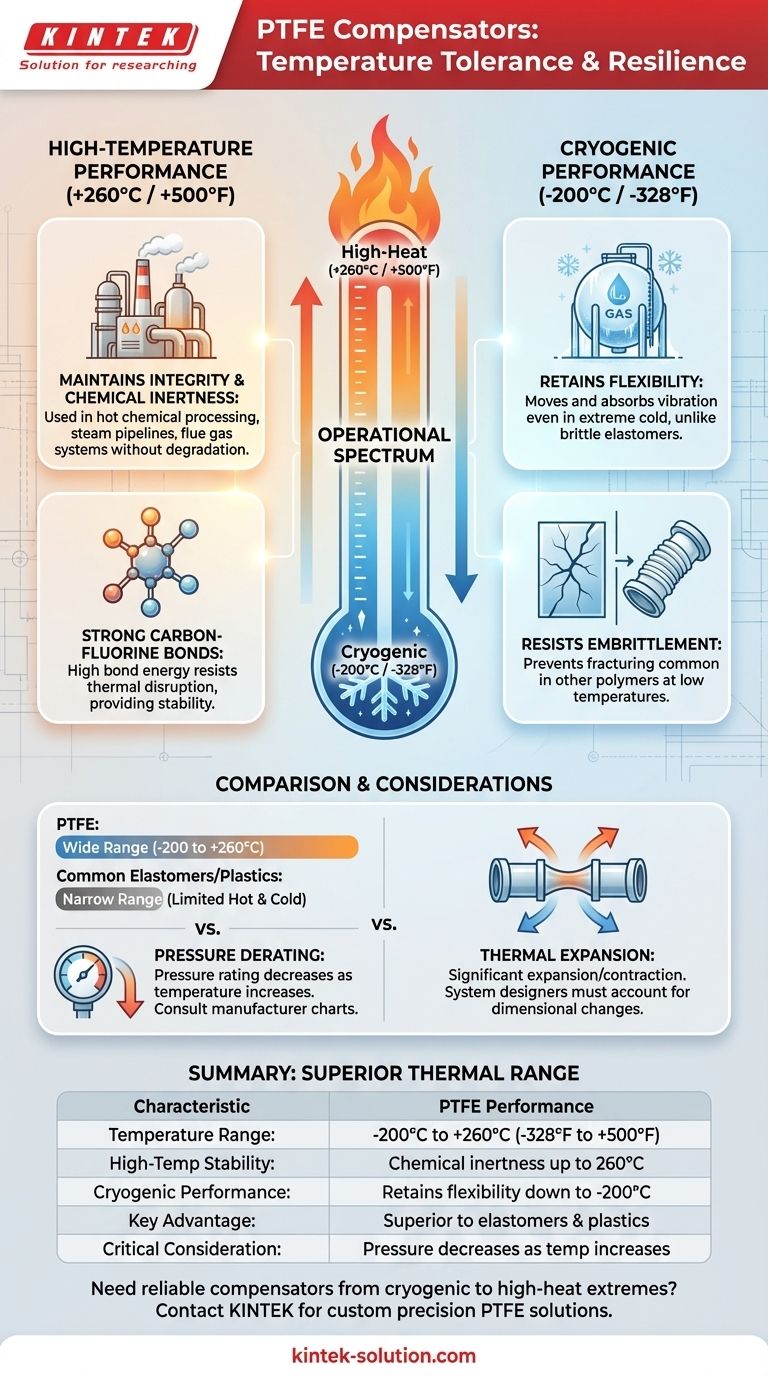

For engineers and system designers, the operational temperature range of a component is a critical safety and performance parameter. PTFE compensators are specified for their exceptional thermal stability, functioning reliably and consistently across a vast temperature spectrum from approximately -200°C to +260°C (-328°F to +500°F). This makes them one of the few flexible materials suitable for both extreme cryogenic services and high-heat industrial processes.

When selecting materials for thermally demanding environments, the choice often dictates system reliability. PTFE's unique molecular structure gives it one of the widest and most stable operating temperature ranges of any polymer, making it a definitive solution where common elastomers or plastics would fail.

Understanding PTFE's Thermal Resilience

The remarkable temperature tolerance of Polytetrafluoroethylene (PTFE) is not an accident; it is a direct result of its molecular architecture. Understanding this provides confidence in its application.

The Source of Its Stability

The strength of the carbon-fluorine bonds in PTFE is one of the strongest single bonds in organic chemistry. This immense bond energy means that a significant amount of thermal energy is required to disrupt the molecular structure, resulting in a very high melting point and inherent stability.

Performance in High-Temperature Environments

Up to its maximum continuous service temperature of 260°C (500°F), PTFE maintains its structural integrity and chemical inertness. This allows it to be used confidently in applications like hot chemical processing, steam pipelines, and industrial flue gas systems without significant degradation or deformation.

Performance in Cryogenic Conditions

At the other extreme, PTFE performs exceptionally well down to -200°C (-328°F). Unlike many elastomers and plastics that become extremely brittle and fracture at low temperatures, PTFE retains a useful degree of flexibility. This property is essential for compensators, which must be able to move and absorb vibration even in cryogenic systems.

How PTFE Compares to Other Materials

To fully appreciate the performance of PTFE, it is useful to compare it to other common industrial materials.

Superiority Over Elastomers

Most common elastomers, such as EPDM or Neoprene, have a much narrower temperature range. They typically degrade quickly at temperatures above 150°C and become rigid and brittle well before reaching cryogenic levels, making PTFE the clear choice for thermal extremes.

An Advantage Over Common Plastics

Standard industrial plastics like Polypropylene or ABS also have far lower thermal limits. Their performance window is a fraction of what PTFE can offer, restricting their use to more moderate temperature applications.

Key Considerations and Trade-offs

While PTFE's thermal range is impressive, a complete technical assessment requires understanding its behavior and limitations within that range.

Pressure Derating at High Temperatures

A critical principle for any compensator is the inverse relationship between temperature and pressure rating. As the operating temperature of a PTFE compensator increases towards its 260°C limit, its maximum allowable working pressure will decrease. Always consult the manufacturer's pressure-temperature curve for your specific component.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it will expand and contract significantly across its operational temperature range. System designers must account for these dimensional changes to prevent undue stress on the component or connected piping.

Grade and Form Factor

The precise temperature tolerance can vary slightly depending on the form of the PTFE, whether it is a machined part, a gasket, a coating, or a composite compensator. While the core material properties remain, the final assembly and any reinforcing materials can influence the ultimate performance characteristics.

Making the Right Choice for Your Goal

Selecting the correct compensator material is essential for system safety, longevity, and performance. Use these guidelines to determine if PTFE fits your specific requirements.

- If your primary focus is high-heat industrial processes: PTFE is an excellent choice for applications like steam or chemical transfer up to 260°C (500°F), where elastomers would rapidly fail.

- If your primary focus is cryogenic applications: PTFE is a proven solution for systems handling liquefied gases down to -200°C (-328°F), as it resists the embrittlement that fractures other polymers.

- If your system involves both extreme temperatures and high pressure: You must verify that your operating conditions fall within the safe zone of the manufacturer's pressure-temperature rating chart for the specific compensator model.

By understanding its fundamental properties, you can confidently specify PTFE for your most thermally demanding applications.

Summary Table:

| Characteristic | PTFE Compensator Performance |

|---|---|

| Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| High-Temperature Stability | Maintains integrity and chemical inertness up to 260°C |

| Cryogenic Performance | Retains flexibility and resists embrittlement down to -200°C |

| Key Advantage | Superior thermal range compared to common elastomers and plastics |

| Critical Consideration | Pressure rating decreases as temperature increases |

Need a compensator that performs reliably from cryogenic to high-heat extremes?

KINTEK specializes in manufacturing high-precision PTFE components, including custom compensators, seals, and liners for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your system operates safely and efficiently across the entire temperature spectrum.

Contact our engineering team today to discuss your specific thermal and pressure requirements. We provide custom fabrication from prototypes to high-volume orders, delivering the precision and reliability your critical applications demand.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers