In the chemical industry, products made from PTFE sheets are primarily those that require extreme chemical resistance and durability. This includes critical components like gaskets, seals, washers, linings for vessels and tanks, and various custom-fabricated rings.

The core reason PTFE is indispensable in chemical processing is not just the components it can form, but its fundamental property of being nearly chemically inert. This allows engineers to safely contain and manage highly corrosive substances that would destroy most other materials.

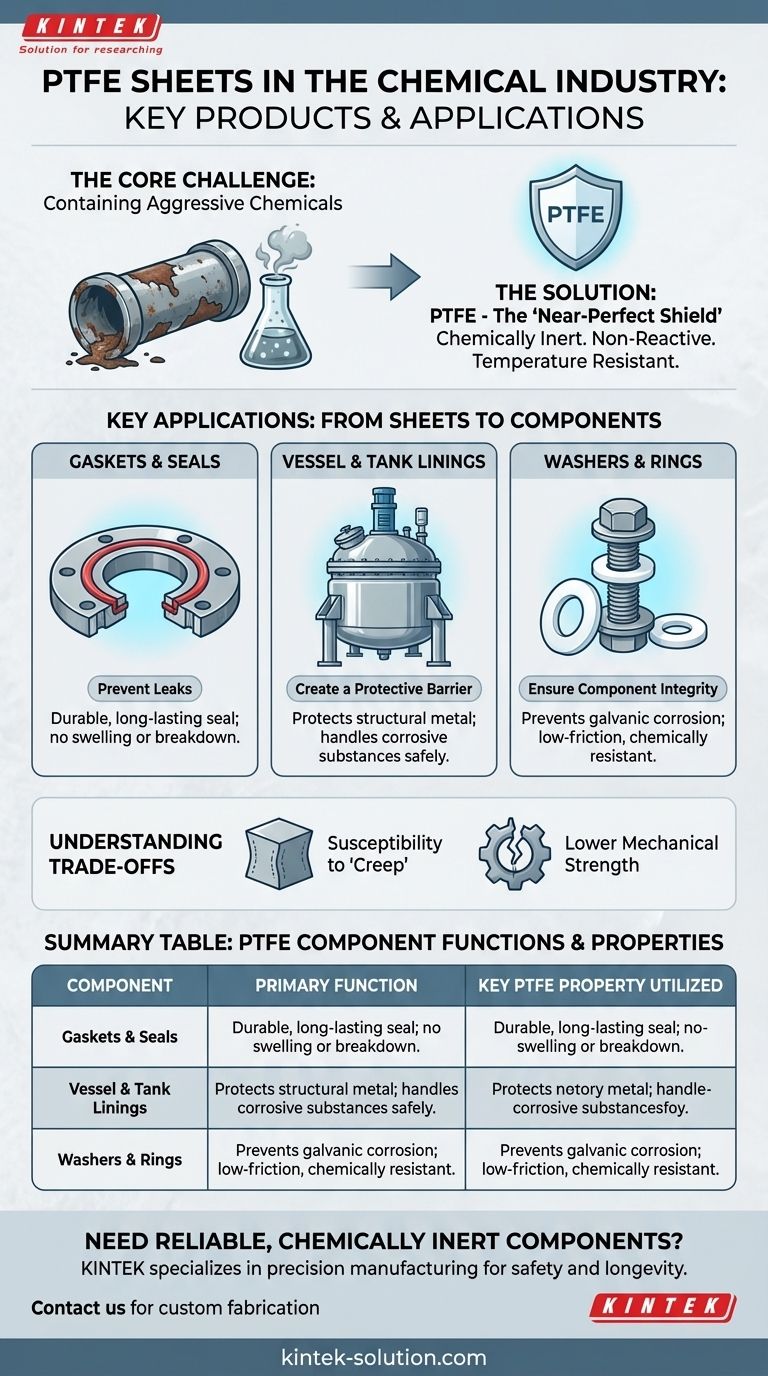

The Core Challenge: Containing Aggressive Chemicals

The chemical processing industry operates under some of the most demanding conditions imaginable. The primary challenge is the safe handling, storage, and transport of substances that are often highly corrosive, reactive, or at extreme temperatures.

Why PTFE is the Ideal Solution

PTFE, or Polytetrafluoroethylene, is a unique polymer that acts as a near-perfect shield in these environments. Its molecular structure makes it exceptionally non-reactive.

This chemical inertness means it will not degrade, dissolve, or contaminate the process media, even when exposed to powerful acids, bases, and solvents. It also maintains its integrity across a wide range of temperatures.

Key Applications of PTFE in Chemical Processing

The properties of PTFE make it the material of choice for fabricating components that form the backbone of chemical processing equipment. Sheets are a common starting form factor for creating these custom parts.

Gaskets and Seals: Preventing Leaks

Gaskets and seals are the most critical components for ensuring system integrity. They are placed between flanges and joints to prevent dangerous leaks.

Because PTFE does not react with the chemicals flowing through pipes and vessels, a PTFE gasket will not swell, weaken, or break down. This ensures a durable, long-lasting seal, which is paramount for safety and operational efficiency.

Linings for Vessels and Tanks: Creating a Protective Barrier

Many chemical reactors and storage tanks are built from steel for structural strength. However, steel is highly susceptible to corrosion from aggressive chemicals.

A PTFE sheet lining is installed inside these vessels to create a non-reactive barrier. This protects the structural metal from the contents, allowing for the safe storage and processing of substances that would otherwise require exotic and prohibitively expensive alloys.

Washers and Rings: Ensuring Component Integrity

In complex assemblies, smaller components like washers and rings play a vital role. They are used to isolate different materials, provide spacing, and act as bearing surfaces.

PTFE washers and rings prevent galvanic corrosion between dissimilar metals and provide a low-friction, chemically resistant surface that ensures bolts, joints, and moving parts operate reliably without seizing or degrading.

Understanding the Trade-offs

While its chemical properties are unmatched, PTFE is not the solution for every single application. Understanding its limitations is key to using it effectively.

Susceptibility to "Creep"

Standard PTFE can be subject to "creep" or "cold flow." This means that under a constant, high-pressure load (like in a bolted flange), the material can slowly deform over time. This is often managed by using filled grades of PTFE or proper engineering design.

Lower Mechanical Strength

Compared to metals or engineering plastics like PEEK, PTFE has lower tensile strength and abrasion resistance. Its value lies in its chemical and thermal properties, not its ability to withstand high physical wear and tear.

Making the Right Choice for Your Application

- If your primary focus is safety and reliability with highly corrosive media: PTFE is the industry standard for creating non-reactive seals, gaskets, and vessel linings.

- If your primary focus is high-temperature chemical sealing: PTFE's excellent thermal stability ensures components maintain their shape and function where other polymers would fail.

- If your application involves high mechanical stress without extreme chemical exposure: You should evaluate other engineering plastics or metals that may offer better resistance to physical wear and deformation.

Ultimately, PTFE's unique chemical immunity makes it a foundational material that enables the safe and efficient operation of the modern chemical industry.

Summary Table:

| Component | Primary Function | Key PTFE Property Utilized |

|---|---|---|

| Gaskets & Seals | Prevent leaks in pipes and flanges | Extreme chemical inertness |

| Vessel & Tank Linings | Protect structural metal from corrosion | Non-reactive barrier |

| Washers & Rings | Isolate materials, prevent seizing | Low friction, chemical resistance |

Need reliable, chemically inert components for your chemical processing equipment?

At KINTEK, we specialize in precision manufacturing of PTFE components—from custom gaskets and seals to complex tank liners—specifically for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components withstand aggressive chemicals and extreme temperatures, enhancing safety and operational longevity.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application