In short, PTFE spring energized seals deliver unmatched reliability in the oil and gas industry by providing leak-tight sealing across extreme temperature and pressure ranges while remaining inert to aggressive chemicals. Their unique design overcomes the common failure points of traditional seals, ensuring operational integrity in the most demanding conditions.

The central challenge in oil and gas sealing is not just preventing leaks, but doing so reliably under a combination of high pressure, extreme temperatures, and corrosive media. PTFE spring energized seals are the definitive solution because the spring provides a constant, resilient force that traditional elastomeric seals cannot, ensuring a consistent seal despite environmental fluctuations and material wear.

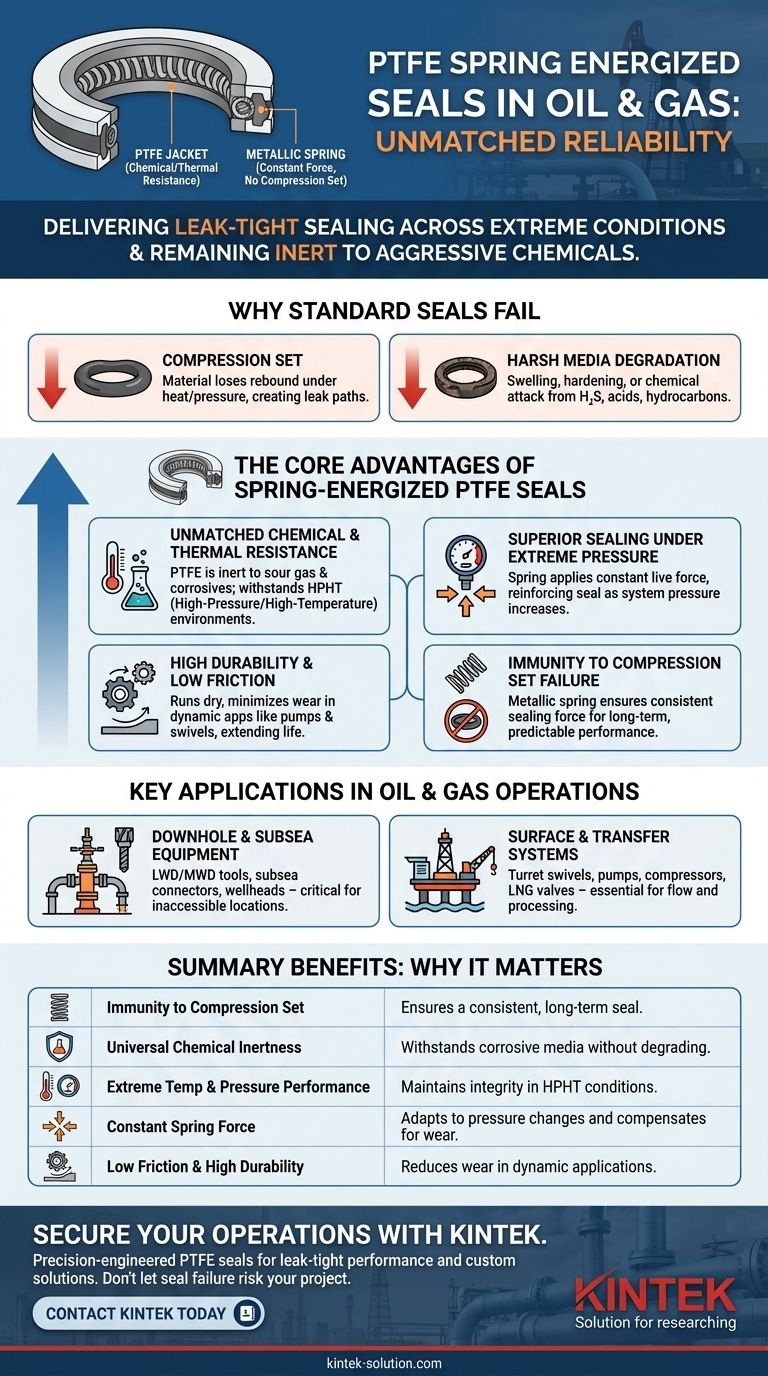

Why Standard Seals Are Insufficient

Before understanding the benefits of a spring-energized design, it's critical to recognize why conventional seals, like rubber O-rings, often fail in oil and gas applications.

The Problem of Compression Set

Most elastomeric seals rely on their own material "squeeze" or compression to create a seal. Over time, especially under high heat and pressure, this material loses its ability to rebound, a failure known as compression set. This permanent deformation creates a leak path.

Degradation from Harsh Media

The oil and gas environment is filled with aggressive chemicals, from sour gas (H₂S) and acid gas to steam and various hydrocarbons. These media can cause standard elastomers to swell, harden, or chemically degrade, leading to rapid seal failure.

The Core Advantages of Spring-Energized PTFE Seals

These seals are specifically engineered to solve the problems of compression set and chemical degradation by combining the properties of a durable polymer jacket with the mechanics of a high-performance spring.

Unmatched Chemical and Thermal Resistance

The seal jacket is made from Polytetrafluoroethylene (PTFE), a polymer renowned for its near-universal chemical inertness. It remains unaffected by the corrosive media found downhole or in processing equipment.

This material also performs exceptionally across a vast temperature spectrum, making it ideal for High-Pressure/High-Temperature (HPHT) environments where other materials would fail.

Superior Sealing Under Extreme Pressure

The internal spring is the core of the design. It applies a constant, live force, pressing the PTFE lips against the sealing surfaces.

This mechanism ensures a tight seal even at low pressures and compensates for any dimensional changes caused by temperature fluctuations or wear. As system pressure increases, it energizes the seal further, reinforcing the sealing force.

High Durability and Low Friction

PTFE has an extremely low coefficient of friction, allowing it to run dry without lubrication and minimizing wear in dynamic applications like pumps and swivels. This extends the service life of both the seal and the mating hardware.

Eliminating Compression Set Failure

Because the sealing force comes from a metallic spring, not the polymer's elasticity, spring energized seals are immune to compression set. The spring guarantees a consistent outward force for the entire life of the seal, providing long-term, predictable performance.

Key Applications in Oil & Gas Operations

The unique capabilities of PTFE spring energized seals make them critical components in a wide range of upstream, midstream, and downstream equipment.

Downhole and Subsea Equipment

In tools for Logging While Drilling (LWD) and Measurement While Drilling (MWD), as well as subsea wellheads and connectors, seal failure is catastrophic. These seals provide the necessary reliability for long-term deployment in inaccessible locations.

Surface and Transfer Systems

They are heavily used in equipment that manages the flow and processing of hydrocarbons. This includes turret swivels on FPSOs, pumps, compressors, transfer systems, and critical valves used in LNG (Liquefied Natural Gas) facilities.

Understanding the Trade-offs

While highly effective, PTFE spring energized seals are a precision component, and their use involves certain considerations.

Higher Initial Cost

These seals are more complex to manufacture than simple elastomeric O-rings. Their initial procurement cost is higher, reflecting their advanced design and superior performance capabilities.

Sensitivity to Surface Finish

To achieve optimal leak-tight performance, the mating hardware surfaces must have a fine finish. The relatively hard PTFE jacket is less forgiving of surface imperfections than a soft elastomer, making proper hardware preparation crucial.

Installation Complexity

Proper installation is critical. The robust design, while durable, can be damaged if not handled and seated correctly. This requires skilled technicians and adherence to proper procedures, unlike the more forgiving installation of a simple O-ring.

Making the Right Choice for Your Application

Selecting a PTFE spring energized seal is a decision to prioritize long-term reliability over initial cost, especially where failure carries significant financial or safety risks.

- If your primary focus is HPHT environments: The seal's ability to maintain integrity across extreme temperature and pressure gradients makes it the default choice.

- If your primary focus is chemical compatibility: For applications involving sour gas, aggressive solvents, or other corrosive media, the inertness of the PTFE jacket is non-negotiable.

- If your primary focus is dynamic, long-life applications: The low-friction and wear-resistant properties ensure extended service intervals in equipment like pumps, compressors, and swivels.

By overcoming the fundamental weaknesses of traditional seals, PTFE spring energized seals provide the operational certainty required to perform in the world's most challenging energy environments.

Summary Table:

| Key Benefit | Why It Matters for Oil & Gas |

|---|---|

| Immunity to Compression Set | Ensures a consistent, long-term seal, unlike elastomers that fail permanently under heat and pressure. |

| Universal Chemical Inertness | Withstands corrosive media like sour gas (H₂S), acids, and hydrocarbons without degrading. |

| Extreme Temperature & Pressure Performance | Maintains integrity in High-Pressure/High-Temperature (HPHT) downhole and subsea conditions. |

| Constant Spring Force | Provides a live, resilient seal that adapts to pressure changes and compensates for wear. |

| Low Friction & High Durability | Reduces wear in dynamic applications (pumps, swivels) and extends service life. |

Secure your operations with precision-engineered PTFE seals from KINTEK.

In the oil and gas industry, seal failure is not an option. KINTEK specializes in manufacturing high-performance PTFE components, including custom spring energized seals, for the most demanding applications in semiconductor, medical, laboratory, and industrial sectors. We deliver the reliability you need through:

- Precision Production: Ensuring exacting tolerances for leak-tight performance.

- Custom Fabrication: From prototype development to high-volume orders, tailored to your specific requirements.

Don't let seal failure risk your project's integrity or safety. Contact KINTEK today to discuss how our PTFE sealing solutions can enhance the performance and longevity of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support