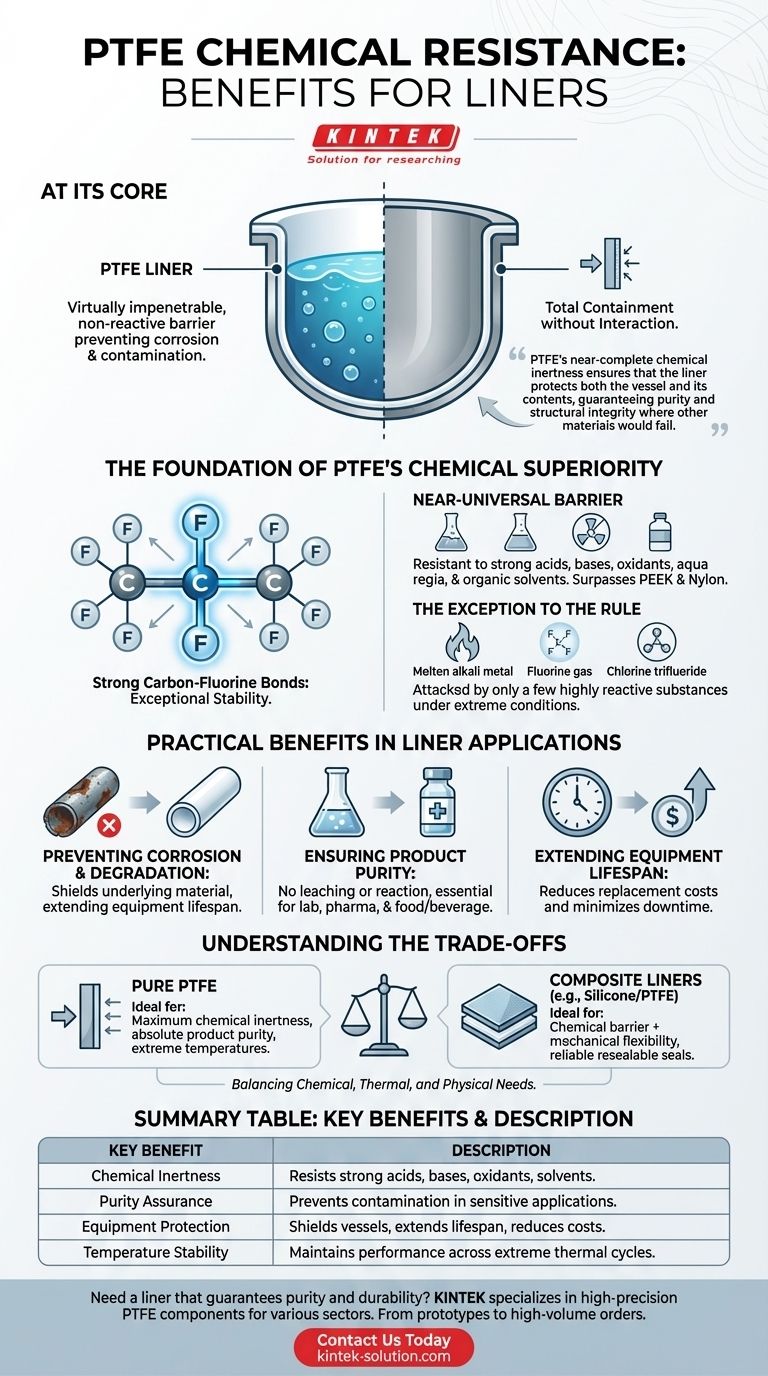

At its core, PTFE's chemical resistance creates a virtually impenetrable and non-reactive barrier. This benefits its use in liners by preventing the container from being corroded by aggressive chemicals and, just as importantly, stopping the liner itself from contaminating the substance being stored.

When handling sensitive or corrosive materials, the goal is total containment without interaction. PTFE's near-complete chemical inertness ensures that the liner protects both the vessel and its contents, guaranteeing purity and structural integrity where other materials would fail.

The Foundation of PTFE's Chemical Superiority

To understand PTFE's benefit as a liner, we must first look at its unique molecular structure. This is not just a surface-level coating; it is a fundamentally non-reactive material.

The Power of Carbon-Fluorine Bonds

PTFE's exceptional stability comes from the incredibly strong bonds between its carbon and fluorine atoms. This molecular structure is so robust that it is highly non-reactive and insoluble in almost all chemicals.

A Near-Universal Barrier

This inertness makes PTFE liners resistant to a vast spectrum of substances. This includes strong acids, bases, strong oxidants, aqua regia, and all organic solvents.

Its performance significantly surpasses that of other high-performance plastics like PEEK and Nylon, establishing it as a premier choice for chemically aggressive environments.

The Exception to the Rule

While virtually inert, PTFE is not invincible. It can be attacked by a few highly reactive and specialized substances, such as molten alkali metals, fluorine gas, and chlorine trifluoride under extreme conditions.

For nearly all industrial and laboratory applications, however, PTFE is considered completely inert.

Practical Benefits in Liner Applications

The chemical properties of PTFE translate directly into tangible advantages when it is used to line pipes, valves, vials, and containers.

Preventing Corrosion and Degradation

The primary function of a PTFE liner is to protect the underlying material of a vessel or pipe. By forming an inert barrier, it prevents corrosive media from ever contacting and degrading the structural components.

Ensuring Product Purity

Because PTFE does not react with or leach into the substances it contains, it is essential for applications demanding high purity. This prevents contamination in laboratory samples, pharmaceuticals, and food and beverage products.

Extending Equipment Lifespan

By shielding equipment from chemical attack, PTFE liners dramatically extend the operational life of expensive valves, pumps, and tanks. This reduces replacement costs and minimizes downtime.

Understanding the Trade-offs

While its chemical resistance is unparalleled, PTFE's properties must be considered within the context of the entire system.

The Role of Combination Materials

In applications requiring both chemical inertness and mechanical flexibility, pure PTFE may not be ideal. This is why composite liners, such as Silicone/PTFE, are common.

In this design, the PTFE layer faces the product, providing the necessary chemical barrier. The silicone layer provides the flexibility and resilience needed to create a consistent, airtight, and resealable seal, especially in vial septa.

Balancing Chemical, Thermal, and Physical Needs

A liner's suitability is a function of more than just one property. PTFE also offers excellent temperature resistance and a low coefficient of friction (non-stick). However, the complete application—including pressure, physical stress, and sealing requirements—dictates whether pure PTFE or a composite material is the right choice.

Making the Right Choice for Your Application

Selecting the correct liner comes down to identifying the most critical requirement for your process.

- If your primary focus is maximum chemical inertness: A pure PTFE liner is the definitive choice for handling the most aggressive chemicals or when ensuring absolute product purity is non-negotiable.

- If your primary focus is a reliable, resealable seal: A Silicone/PTFE composite liner offers the best of both worlds, pairing PTFE's inert barrier with silicone's superior flexibility and sealing capability.

- If your primary focus is high-temperature stability: PTFE's ability to perform across extreme temperature ranges makes it a safe and durable choice for processes involving thermal cycling.

Ultimately, choosing a PTFE liner is a decision to prioritize unwavering reliability and purity in the face of chemical challenges.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Resists strong acids, bases, oxidants, and solvents, ensuring no reaction with contents. |

| Purity Assurance | Prevents contamination in sensitive applications like pharmaceuticals and labs. |

| Equipment Protection | Shields vessels and pipes from corrosion, extending lifespan and reducing costs. |

| Temperature Stability | Maintains performance across extreme thermal cycles. |

Need a liner that guarantees purity and durability? KINTEK specializes in manufacturing high-precision PTFE components, including custom liners, seals, and labware for the semiconductor, medical, and industrial sectors. Whether you require a pure PTFE barrier for aggressive chemicals or a composite design for superior sealing, we deliver solutions from prototypes to high-volume orders. Contact us today to discuss your specific application and ensure total containment without compromise!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How do PTFE spring-energized seals perform in defense and nuclear environments? Engineered for Extreme Reliability.

- How is CNC machining used with Teflon plastic sheets for industrial applications? Achieve High-Performance Custom Parts

- How does sintering affect the properties of PTFE? Control Crystallinity for Hard or Flexible Parts

- How does PTFE's low friction coefficient benefit mechanical systems? Boost Efficiency & Extend Lifespan

- What are PTFE washers and what are their key properties? Specialized Seals for Extreme Conditions

- In which industries is RPTFE particularly suitable for throttle valves? Ensure Purity and Durability

- What are the key properties of Teflon (PTFE) used in custom parts? | Achieve Peak Performance

- What are the key considerations for chemical industry applications of PTFE O-ring seals? Ensure Reliability in Aggressive Environments