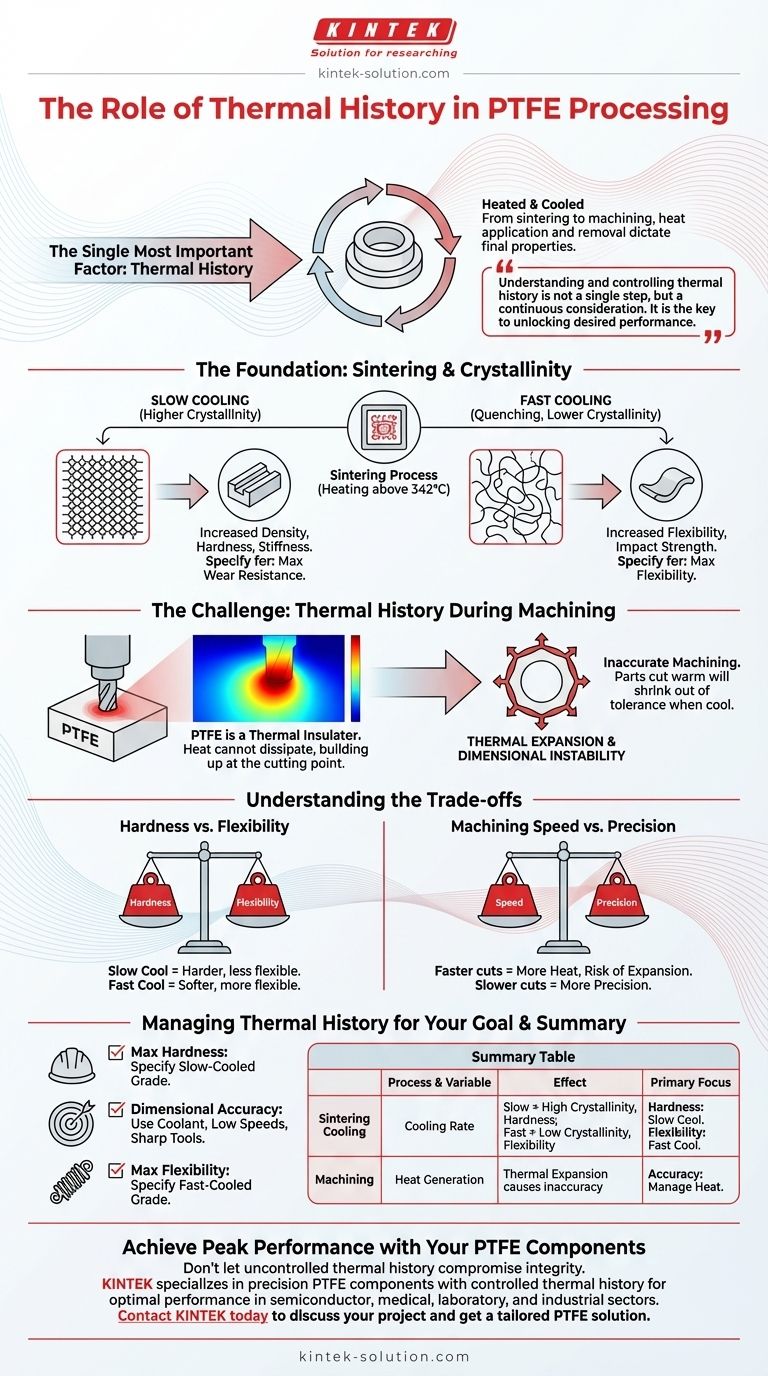

The single most important factor determining the final physical properties of a Polytetrafluoroethylene (PTFE) component is its thermal history. This history begins during the initial sintering and cooling cycle and extends through any subsequent machining processes. How heat is applied and, more critically, how it is removed, dictates everything from the material's hardness and flexibility to the dimensional accuracy of the finished part.

Understanding and controlling thermal history is not a single step, but a continuous consideration. It is the key to unlocking the desired performance from a PTFE component and avoiding costly manufacturing defects caused by thermal expansion and instability.

The Foundation: Sintering and Crystallinity

The initial manufacturing process creates the fundamental material properties of the PTFE stock. This is where the most significant aspects of its thermal history are established.

The Sintering Process

Sintering is the process of heating compressed PTFE powder above its crystalline melting point (around 342°C / 648°F). This allows the individual particles to fuse together into a solid, void-free mass.

The Critical Cooling Phase

After sintering, the rate at which the PTFE is cooled back to room temperature is the most crucial variable. This cooling rate directly controls the material's crystallinity, which is the degree of ordered alignment within the polymer chains.

Slow Cooling vs. Fast Cooling

A slow cooling cycle allows the polymer chains more time to arrange themselves into orderly crystalline structures. This results in higher crystallinity, leading to increased density, hardness, and stiffness in the final material.

Conversely, fast cooling (quenching) "freezes" the polymer chains in a more disordered, amorphous state. This results in lower crystallinity, making the PTFE softer, more flexible, and having a higher impact strength.

The Challenge: Thermal History During Machining

A component's thermal history does not end after its initial cooling. Heat introduced during secondary processes like machining can easily compromise the final part's integrity.

PTFE's Insulating Nature

PTFE is an excellent thermal insulator. While this is a valuable property in many applications, it creates a significant challenge during machining. The material cannot effectively dissipate the heat generated by cutting tools.

The Problem of Thermal Expansion

This inability to dissipate heat causes it to build up at the point of contact between the tool and the workpiece. Due to its high coefficient of thermal expansion, the PTFE expands significantly in this localized hot spot.

Consequence: Dimensional Instability

This expansion is the primary cause of inaccurate machining. A feature cut to precise dimensions on a warm, expanded part will shrink and fall out of tolerance as the component cools to a stable ambient temperature.

Understanding the Trade-offs

Controlling PTFE's thermal history always involves balancing competing properties and process requirements.

Hardness vs. Flexibility

Choosing a cooling rate is a direct trade-off. The higher hardness and wear resistance achieved through slow cooling comes at the cost of reduced flexibility. Conversely, the superior flexibility from fast cooling sacrifices surface hardness.

Machining Speed vs. Precision

During machining, aggressive cutting speeds and feeds may increase production throughput, but they also generate more heat. This elevates the risk of thermal expansion and dimensional errors, requiring a trade-off between manufacturing speed and the precision of the final part.

Managing Thermal History for Your Goal

To achieve predictable and reliable results with PTFE, you must align your thermal management strategy with your primary objective.

- If your primary focus is maximum hardness and wear resistance: Specify a slow-cooled or post-sintered annealed grade of PTFE to ensure the highest possible level of crystallinity.

- If your primary focus is dimensional accuracy in a machined part: Use sharp tools, low cutting speeds, and a constant flood of coolant to actively manage heat and prevent thermal expansion during the process.

- If your primary focus is flexibility or impact strength: Specify a fast-cooled (quenched) grade of PTFE to lock in a more amorphous, less crystalline molecular structure.

Ultimately, mastering the thermal properties of PTFE is the key to transforming it from a raw material into a high-performance, precision component.

Summary Table:

| Thermal Process | Key Variable | Effect on PTFE Properties |

|---|---|---|

| Sintering Cooling | Cooling Rate | Slow Cooling: High crystallinity, increased hardness, stiffness. Fast Cooling: Low crystallinity, increased flexibility, impact strength. |

| Machining | Heat Generation | Localized thermal expansion causes dimensional inaccuracy if not managed with coolant and proper tooling. |

| Property Trade-off | Primary Focus | Hardness/Wear Resistance: Use slow-cooled PTFE. Dimensional Accuracy: Manage heat during machining. Flexibility: Use fast-cooled PTFE. |

Achieve Peak Performance with Your PTFE Components

Don't let uncontrolled thermal history compromise your part's integrity. The precise management of heat during sintering and machining is critical for achieving the exact properties—be it hardness, flexibility, or dimensional stability—that your application demands.

At KINTEK, we specialize in manufacturing precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your custom PTFE parts—from prototypes to high-volume orders—are produced with a controlled thermal history to guarantee optimal performance and avoid costly defects.

Contact KINTEK today to discuss your project requirements and let our experts deliver a PTFE solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance