Choosing between PTFE and metal components is not a matter of which is universally superior, but which is precisely suited for the specific demands of your application. While Polytetrafluoroethylene (PTFE) offers a unique combination of properties like chemical inertness and low friction, metals provide unparalleled strength and temperature resistance. The optimal choice depends entirely on the operational environment and performance requirements.

The core decision hinges on a fundamental trade-off: select PTFE for its exceptional chemical resistance, electrical insulation, and low-friction surface, or choose metal for its superior mechanical strength, rigidity, and ability to withstand extreme temperatures.

Key Differentiators: PTFE vs. Metal

Understanding the distinct properties of each material class is the first step toward making an informed decision. These materials do not compete so much as they offer entirely different solutions to engineering problems.

Mechanical Strength and Rigidity

Metals, such as steel, aluminum, and titanium, offer vastly superior tensile strength, stiffness, and hardness. They are the default choice for load-bearing structures, high-pressure systems, and components requiring dimensional stability under stress.

PTFE is a relatively soft material. It exhibits excellent toughness but lacks the rigidity of metal and can be prone to creep, or slow deformation under a sustained load.

Weight and Density

PTFE is significantly lighter than any structural metal. Its low density makes it an ideal choice for applications where weight reduction is a critical design factor, such as in aerospace or mobile equipment.

Temperature Resistance

Most metals maintain their structural integrity at very high temperatures, often many hundreds or even thousands of degrees Celsius.

PTFE has an impressive operating temperature range for a polymer, typically from -200°C to +260°C (-328°F to +500°F). Beyond this range, it begins to degrade, making metals the only viable option for high-heat applications.

Chemical and Corrosion Resistance

This is PTFE's defining advantage. It is chemically inert to nearly all industrial chemicals, solvents, and corrosive agents, making it indispensable in chemical processing, pharmaceuticals, and semiconductor manufacturing.

While some metals offer good corrosion resistance (like stainless steel or titanium), most are susceptible to corrosion or chemical attack without special coatings or alloys.

Friction and Wear

PTFE has one of the lowest coefficients of friction of any solid material, often referred to as "non-stick." This makes it ideal for bearings, seals, and other low-friction, self-lubricating applications.

Metals have high coefficients of friction and require lubrication to prevent galling and wear in moving applications.

Electrical and Thermal Conductivity

Metals are excellent electrical and thermal conductors. This property is essential for applications ranging from electrical wiring and heat sinks to heat exchangers.

PTFE is an outstanding electrical and thermal insulator. Its high dielectric strength makes it a top choice for insulating high-voltage cables and electronic components.

Understanding the Critical Trade-offs

Choosing a material is always an exercise in balancing competing requirements. Recognizing the inherent limitations of both PTFE and metal is crucial for avoiding design failures.

The Strength vs. Inertness Dilemma

The most common trade-off is between mechanical performance and chemical compatibility. You cannot get the strength of steel with the chemical inertness of PTFE in a single material.

If a component must withstand high mechanical loads and harsh chemicals, engineers often design composite parts, such as a metal housing with a PTFE liner.

Machinability and Precision

Both materials are suitable for precision machining, but the techniques and outcomes differ. Metals can hold extremely tight tolerances and produce very sharp features due to their rigidity.

Machining PTFE requires specialized knowledge to manage its softness and thermal expansion, but complex and precise components are readily achievable.

Cost and Manufacturing

Material and manufacturing costs can vary dramatically. Raw PTFE can be more expensive than common metals like aluminum or carbon steel, but specialized metal alloys can be far more costly.

The complexity of the final part and the manufacturing process chosen will ultimately be a major factor in the final component cost.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical requirement of your project.

- If your primary focus is mechanical load and rigidity: Choose metal for its unmatched strength and stiffness.

- If your primary focus is chemical resistance or purity: Choose PTFE for its near-universal chemical inertness.

- If your primary focus is a low-friction, non-stick surface: Choose PTFE for its self-lubricating properties.

- If your primary focus is high-temperature stability (above 260°C / 500°F): Choose a suitable metal alloy.

- If your primary focus is electrical insulation or weight reduction: Choose PTFE for its dielectric strength and low density.

Ultimately, selecting the correct material is about aligning its inherent properties with the non-negotiable demands of your design.

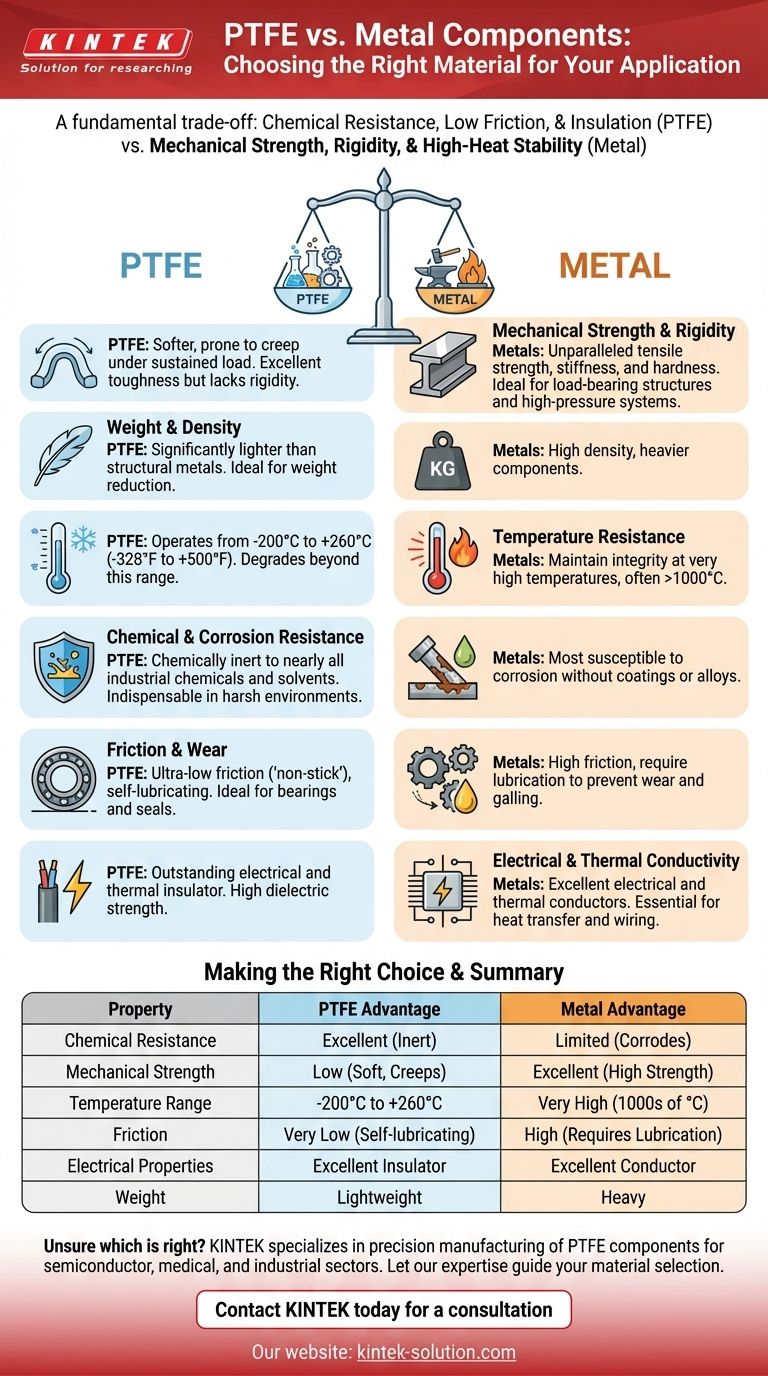

Summary Table:

| Property | PTFE Advantage | Metal Advantage |

|---|---|---|

| Chemical Resistance | Excellent (Inert) | Limited (Corrodes) |

| Mechanical Strength | Low (Soft, Creeps) | Excellent (High Strength) |

| Temperature Range | -200°C to +260°C | Very High (1000s of °C) |

| Friction | Very Low (Self-lubricating) | High (Requires Lubrication) |

| Electrical Properties | Excellent Insulator | Excellent Conductor |

| Weight | Lightweight | Heavy |

Unsure which material is right for your component?

This comparison highlights the fundamental trade-offs. For projects in the semiconductor, medical, laboratory, or industrial sectors, the choice is critical to performance and longevity.

KINTEK specializes in precision manufacturing of PTFE components—including custom seals, liners, and labware. We help you navigate these trade-offs to select or fabricate the optimal part, from prototypes to high-volume production.

Let our expertise guide your material selection and ensure your project's success.

Contact KINTEK today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications