At its core, PTFE is uniquely suited for the food industry because it combines regulatory safety approval with a set of physical properties that prevent contamination and withstand the sector's demanding operational conditions. Key attributes include its FDA-approved food-grade status, chemical inertness, superior non-stick surface, and resilience to both high temperatures and aggressive cleaning agents.

The critical insight is that PTFE is not just a compliant material; it's an active contributor to food safety and operational efficiency. Its properties are uniquely aligned to solve the core challenges of hygiene, product purity, and equipment durability in food processing environments.

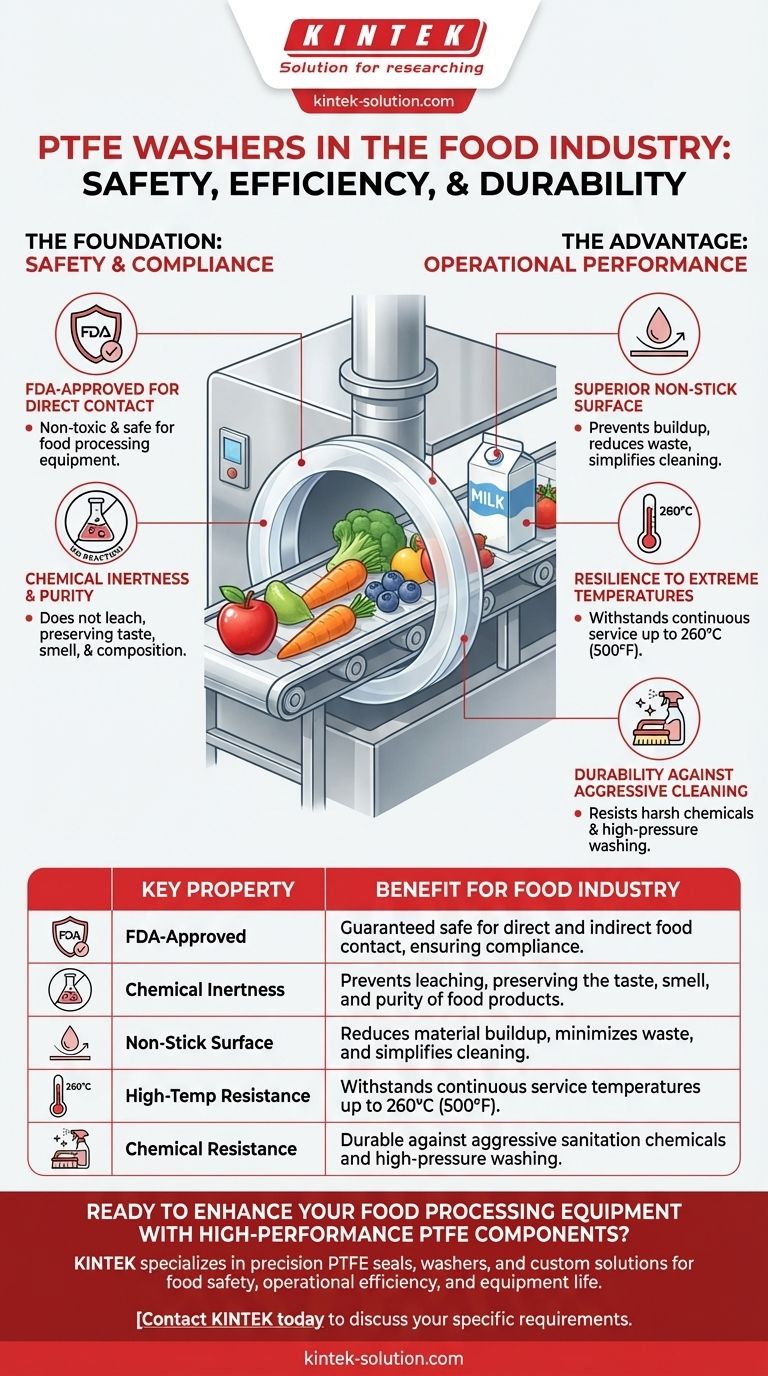

The Foundation: Safety and Compliance

In any food-related application, material safety is the non-negotiable starting point. PTFE provides a verified foundation of compliance and purity that makes it a trusted choice for direct and indirect food contact.

FDA-Approved for Direct Contact

PTFE is available in grades that are FDA-approved for food contact. This certification is the primary gatekeeper, ensuring the material is non-toxic and safe for use in equipment that processes consumables.

Chemical Inertness and Purity

PTFE is a fluoropolymer known for its exceptional chemical resistance. It does not react with or leach into food products, ensuring that the taste, smell, and composition of the food remain unaltered. This is why it's widely used for gaskets and seals in the dairy and beverage industries, where product purity is paramount.

The Advantage: Operational Performance

Beyond safety, PTFE offers distinct performance benefits that enhance the efficiency, hygiene, and durability of food processing machinery. These properties actively solve common operational problems.

Superior Non-Stick Surface

The most famous property of PTFE is its extremely low coefficient of friction, creating a non-stick surface. In food processing, this prevents food, grease, and other materials from sticking to components like washers, gaskets, and conveyor belts. This dramatically reduces material buildup, minimizes waste, and simplifies cleaning protocols.

Resilience to Extreme Temperatures

Food processing often involves extreme heat, from baking to sterilization. PTFE can reliably tolerate continuous service temperatures up to 260°C (500°F). This heat resistance ensures that components like washers and seals maintain their integrity and performance without degrading.

Durability Against Aggressive Cleaning

The food industry relies on aggressive cleaning and sanitation regimens to maintain hygiene. PTFE’s chemical resistance means it can easily withstand harsh cleaning chemicals and high-pressure washing without corroding or breaking down, ensuring a long service life for components.

Understanding Key Material Considerations

While PTFE is highly effective, it's essential to understand its characteristics to apply it correctly. Choosing the right material involves recognizing its strengths and limitations.

The Importance of "Food-Grade" Specification

It is critical to ensure you are sourcing certified "food-grade" PTFE. Standard industrial-grade PTFE may contain fillers or be processed in a way that does not meet FDA requirements. Always verify the material's certification for your specific application.

Mechanical Properties Under Load

PTFE is a relatively soft material. While this helps it create excellent seals, it can be susceptible to "creep" or deformation under sustained high pressure or load. For high-stress structural applications, filled versions of PTFE or alternative materials may be more appropriate.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision that aligns with specific operational goals. Your primary objective will determine which of its properties is most valuable.

- If your primary focus is regulatory compliance and product purity: PTFE's FDA-approved status and chemical inertness provide the highest assurance of food safety.

- If your primary focus is operational efficiency and hygiene: Its non-stick surface is the key benefit, preventing buildup, reducing waste, and making sanitation faster and more effective.

- If your primary focus is equipment durability in harsh environments: PTFE's resistance to high temperatures and aggressive cleaning chemicals ensures long component life and reliable performance.

By understanding these core properties, you can confidently specify PTFE as a material that enhances both food safety and processing performance.

Summary Table:

| Key Property | Benefit for Food Industry |

|---|---|

| FDA-Approved | Guaranteed safe for direct and indirect food contact, ensuring compliance. |

| Chemical Inertness | Prevents leaching, preserving the taste, smell, and purity of food products. |

| Non-Stick Surface | Reduces material buildup, minimizes waste, and simplifies cleaning. |

| High-Temp Resistance | Withstands continuous service temperatures up to 260°C (500°F). |

| Chemical Resistance | Durable against aggressive sanitation chemicals and high-pressure washing. |

Ready to enhance your food processing equipment with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, washers, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures that your components meet the stringent demands of the food industry, from prototypes to high-volume orders.

We prioritize precision production and custom fabrication to deliver parts that guarantee food safety, improve operational efficiency, and extend equipment life.

Contact KINTEK today to discuss your specific requirements and get a quote for reliable, food-grade PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is the PTFE ball valve considered a popular choice in various industries? Unmatched Reliability in Demanding Environments

- What makes PTFE special in terms of friction? Achieve Unmatched Efficiency with Self-Lubricating Components

- What role does temperature stability play in PTFE coated fasteners? Ensuring Reliability in Extreme Environments

- What makes Teflon gland fillers effective for sealing applications in the chemical industry? Superior Chemical Resistance and Reliability

- Why are PTFE envelope gaskets suitable for food processing and pharmaceutical applications? Ensure Product Purity and Compliance

- How does the lifespan of PTFE oil seals compare to other types? Achieve 10,000-50,000 Hours of Reliability

- What are the key properties of PTFE that make it suitable for sealing rings? Unmatched Chemical & Thermal Resistance

- What are the key properties of Teflon (PTFE) that make it suitable for machining? Balancing Performance with Machining Challenges