The primary advantages of PTFE washers stem from a unique combination of three core properties: near-universal chemical resistance, an extremely wide operating temperature range, and the lowest coefficient of friction of any solid material. This trifecta makes PTFE (Polytetrafluoroethylene) an ideal choice for demanding sealing and insulating applications where other non-metallic materials would quickly fail.

Choosing the right non-metallic washer requires matching the material's properties to the specific environmental stress. PTFE's unique combination of chemical inertness, thermal stability, and unparalleled low friction makes it the definitive choice for applications involving aggressive chemicals, temperature extremes, or dynamic sliding contact.

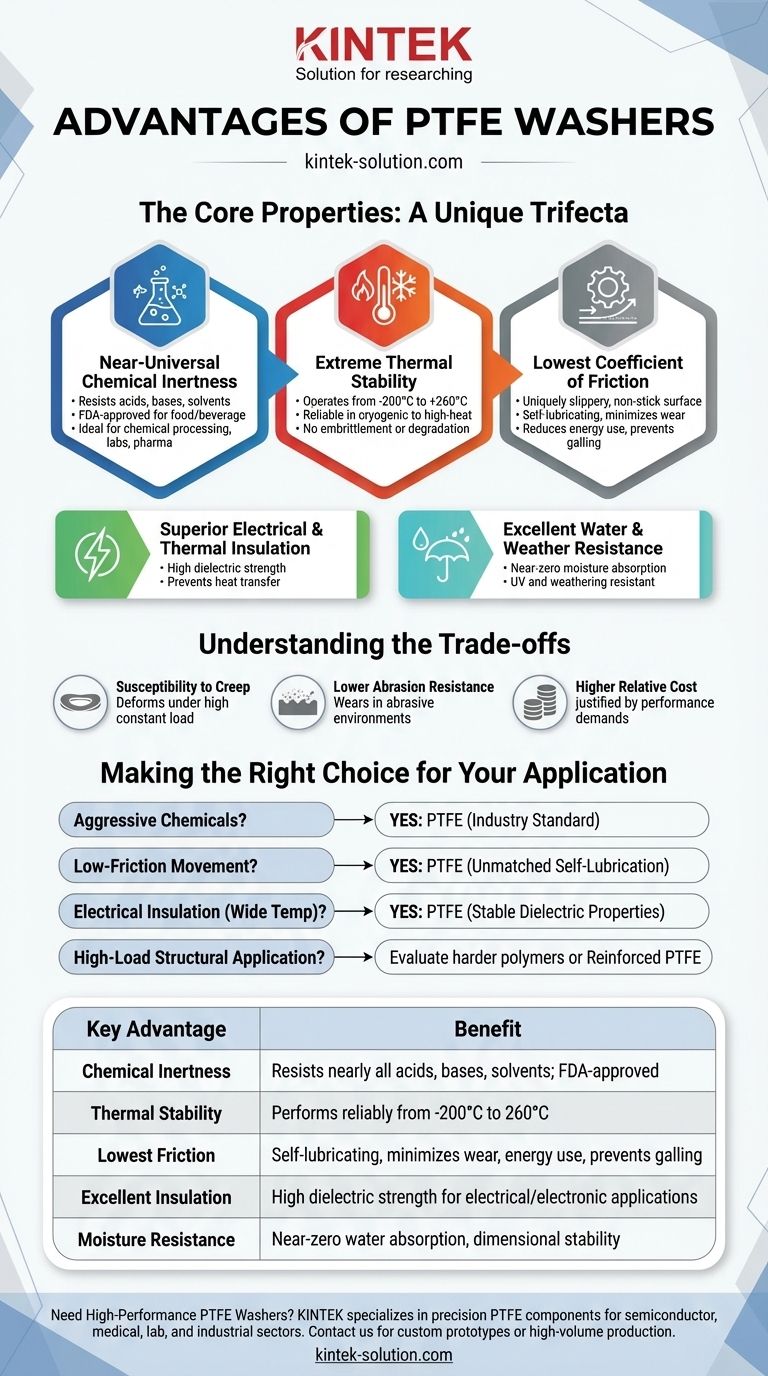

The Core Properties of PTFE Washers

To understand why PTFE is specified for critical applications, it's essential to break down its distinct material characteristics. These properties work in concert to deliver reliable performance in challenging conditions.

Unmatched Chemical Inertness

PTFE is virtually non-reactive and resists nearly all industrial chemicals, acids, and bases. This makes it an indispensable material in chemical processing, laboratories, and pharmaceutical manufacturing.

Because of this inertness and its non-stick surface, PTFE is also FDA-approved for use in food and beverage applications, where purity and ease of cleaning are paramount.

Exceptional Thermal Stability

PTFE washers perform reliably across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This allows them to function effectively in everything from cryogenic applications to high-heat industrial equipment without becoming brittle or degrading, a range that far exceeds that of most other polymers.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material, giving it a uniquely slippery, non-stick surface.

This self-lubricating property is critical for applications with rotating or sliding parts, as it minimizes wear, reduces operational energy, and prevents galling between surfaces. It also allows for easier installation.

Superior Electrical and Thermal Insulation

PTFE is an outstanding electrical insulator with high dielectric strength. It does not conduct electricity, making it an ideal material for isolating components in electronics and electrical equipment.

It also serves as an effective thermal insulator, helping to prevent heat transfer between assembled components.

Excellent Water and Weather Resistance

PTFE is almost completely resistant to water, exhibiting near-zero moisture absorption. This ensures dimensional stability and prevents the material from swelling or degrading in humid or submerged environments.

Its inherent resistance to UV radiation and weathering also contributes to its long service life in exposed applications.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's limitations to ensure it is specified correctly.

Susceptibility to Creep

PTFE is a relatively soft material. Under a high, constant compressive load, it can be susceptible to "creep" or "cold flow," where the material slowly deforms over time. For this reason, it is not ideal for high-pressure structural applications without reinforcement.

Lower Abrasion Resistance

While its low-friction surface reduces wear in sliding applications, PTFE is not as resistant to abrasion from hard, sharp particles as other engineering polymers like PEEK or Nylon. In environments with abrasive contaminants, it may wear more quickly.

Higher Relative Cost

PTFE is a high-performance polymer, and its cost is typically higher than that of common commodity plastics like polyethylene or polypropylene. Its use is justified when the application's performance demands exceed the capabilities of less expensive materials.

Making the Right Choice for Your Application

Selecting the correct washer material requires a clear understanding of your primary engineering goal. PTFE is not a universal solution, but it is an unbeatable one for its intended applications.

- If your primary focus is sealing against aggressive chemicals: PTFE is the industry standard due to its near-universal chemical inertness.

- If your primary focus is low-friction movement for dynamic parts: PTFE's self-lubricating, non-stick surface is unmatched among solid materials.

- If your primary focus is electrical insulation across a wide temperature range: PTFE's dielectric properties remain stable in both cryogenic and high-heat conditions.

- If your primary focus is a high-load structural application: You should evaluate harder polymers or consider reinforced PTFE, as standard PTFE can be prone to creep.

By understanding PTFE's unique profile of strengths and limitations, you can confidently specify it for the demanding environments where it truly excels.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Chemical Inertness | Resists nearly all acids, bases, and solvents; FDA-approved for food/medical use. |

| Thermal Stability | Performs reliably from cryogenic (-200°C) to high-heat (260°C) environments. |

| Lowest Friction | Self-lubricating surface minimizes wear, reduces energy use, and prevents galling. |

| Excellent Insulation | High dielectric strength and thermal insulation for electrical/electronic applications. |

| Moisture Resistance | Near-zero water absorption ensures dimensional stability in wet or humid conditions. |

Need High-Performance PTFE Washers for Your Application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right PTFE solution—whether you require custom prototypes or high-volume production—to handle aggressive chemicals, extreme temperatures, and demanding dynamic applications.

Contact us today to discuss your specific requirements and leverage our precision production capabilities for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability