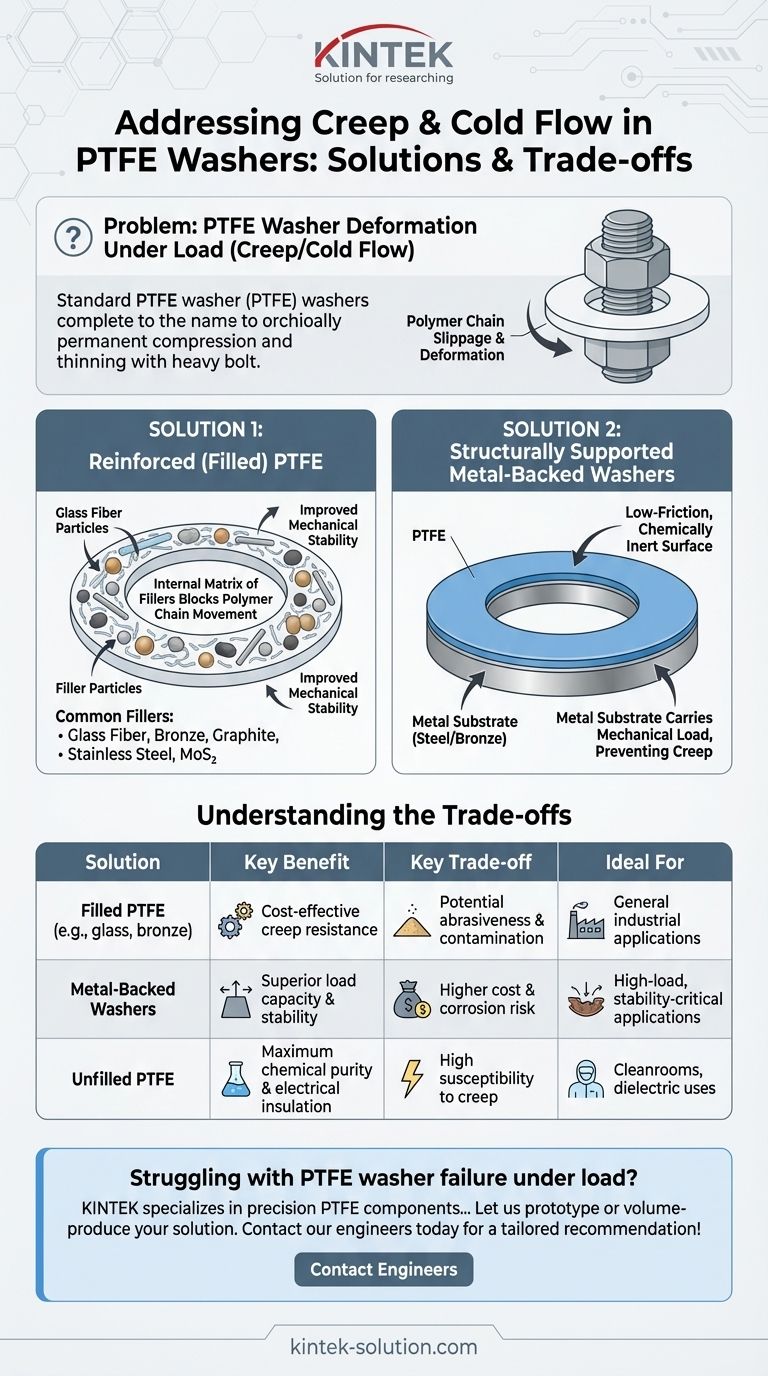

To address creep and cold flow in PTFE washers, the two primary solutions are to use reinforced (filled) grades of PTFE or to employ structurally supported metal-backed washers. These methods improve the material's mechanical stability under constant load, preventing the deformation inherent in standard, unfilled PTFE.

The core challenge is not simply stopping PTFE from deforming, but doing so without introducing new problems. The optimal solution depends on a careful trade-off between the need for mechanical stability and other critical application requirements like chemical purity, wear on mating parts, and electrical insulation.

Understanding the Root Problem: Creep in PTFE

What is Creep (or Cold Flow)?

Creep, often called cold flow, is the tendency of a solid material to deform permanently over time when subjected to a persistent mechanical stress.

This is especially prevalent in soft polymers like PTFE. Under a constant load, like a tightened bolt, the long polymer chains within the material will slowly slip past one another, causing the washer to thin out and lose its clamping force.

Why Standard PTFE is Susceptible

Pure PTFE has an exceptionally low coefficient of friction, which is one of its most valued properties. However, this same molecular slipperiness, combined with its relative softness, is what makes it prone to cold flow.

Primary Solutions to Counteract PTFE Creep

To mitigate this natural tendency, the PTFE must be mechanically constrained. This is achieved either internally with fillers or externally with structural support.

Solution 1: Reinforcing with Fillers

The most common strategy is to create a composite material by adding a filler to the PTFE resin before it is molded. These fillers create an internal matrix that physically blocks the PTFE polymer chains from moving.

Common fillers include glass fiber, bronze, graphite, stainless steel, and molybdenum disulfide (MoS₂). Each one imparts a different balance of properties, but all serve to drastically improve creep resistance.

Solution 2: Structural Support with Metal Backing

This approach involves bonding a thin layer of PTFE to a rigid metal washer, typically made of steel or bronze.

In this design, the metal backing carries the mechanical load, preventing any possibility of creep. The PTFE layer simply provides the low-friction, chemically inert surface required for the application.

Understanding the Trade-offs of Each Solution

Choosing a solution requires a clear understanding of the potential downsides, as improving creep resistance often comes at a cost to other properties.

The Downsides of Filled PTFE

While effective, fillers fundamentally alter the nature of the material.

Abrasiveness: Hard fillers, particularly glass fiber, can increase wear on softer mating surfaces like aluminum or other plastics.

Contamination: The filler material can shed particles, making many filled grades unsuitable for high-purity applications in the food, medical, or semiconductor industries.

Altered Electrical Properties: Standard PTFE is an excellent electrical insulator. Adding conductive fillers like graphite, bronze, or stainless steel will destroy this property, making the material unsuitable for dielectric applications.

Limitations of Metal-Backed Washers

This design provides superior mechanical stability but has its own set of constraints.

Complexity and Cost: These are composite parts that are more complex and expensive to manufacture than a simple molded washer.

Corrosion Potential: The metal backing introduces a potential point of failure from corrosion if the application environment is not compatible with the chosen metal.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important requirement of your design.

- If your primary focus is maximum load capacity and stability: A metal-backed washer is almost always the superior choice, as the metal substrate handles the entire mechanical load.

- If your primary focus is a cost-effective balance of performance: A filled PTFE, such as glass- or bronze-filled, provides a significant improvement in creep resistance for most industrial applications.

- If your primary focus is a clean environment or electrical insulation: You must carefully select a non-contaminating, non-conductive filler or accept the inherent creep of unfilled PTFE if purity and dielectric strength cannot be compromised.

By understanding these trade-offs, you can select a washer that provides the necessary stability without compromising other critical aspects of your design.

Summary Table:

| Solution | Key Benefit | Key Trade-off | Ideal For |

|---|---|---|---|

| Filled PTFE (e.g., glass, bronze) | Cost-effective creep resistance | Potential abrasiveness & contamination | General industrial applications |

| Metal-Backed Washers | Superior load capacity & stability | Higher cost & corrosion risk | High-load, stability-critical applications |

| Unfilled PTFE | Maximum chemical purity & electrical insulation | High susceptibility to creep | Cleanrooms, dielectric uses |

Struggling with PTFE washer failure under load? KINTEK specializes in precision PTFE components—from custom seals and liners to labware—for semiconductor, medical, and industrial applications. Our expertise in filled PTFE formulations and metal-backed designs ensures your washers resist creep without compromising on purity, wear, or insulation. Let us prototype or volume-produce your solution. Contact our engineers today for a tailored recommendation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability