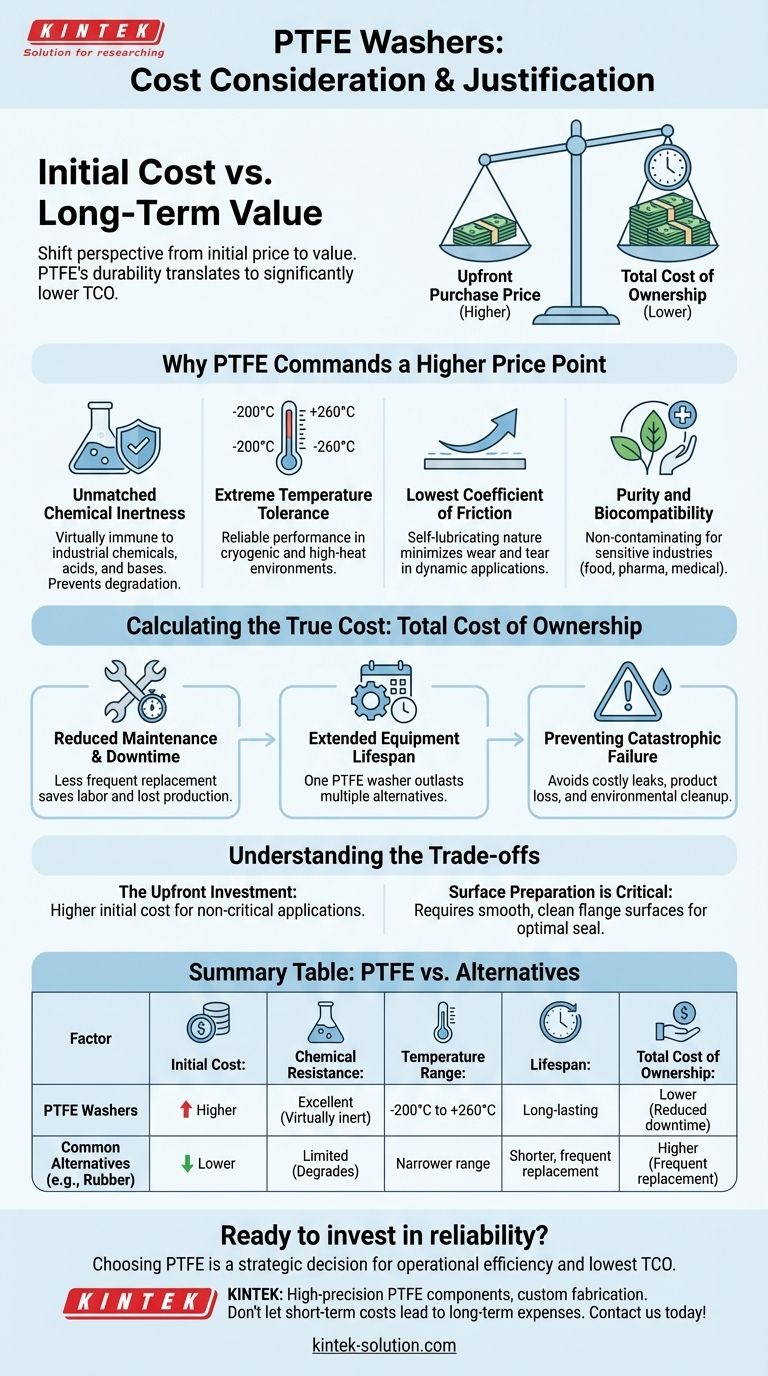

At first glance, PTFE washers appear more expensive than common alternatives like rubber or fiber. This higher initial purchase price is a valid consideration, but it represents only a fraction of the total cost equation. The justification for this cost lies in PTFE's exceptional durability and performance characteristics, which translate into a significantly lower total cost of ownership over the component's lifespan.

The core consideration is shifting your perspective from upfront purchase price to long-term value. The higher initial investment in PTFE is often justified by drastically reduced maintenance, minimal downtime, and superior reliability in demanding environments where cheaper materials would quickly fail.

Why PTFE Commands a Higher Price Point

The manufacturing process and raw material properties that give PTFE its superior performance characteristics are inherently more complex than those for traditional elastomers. This investment delivers tangible benefits.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack from almost all industrial chemicals, acids, and bases. This resistance prevents the degradation, swelling, or breakdown that other materials experience, ensuring a long-lasting, reliable seal in corrosive environments.

Extreme Temperature Tolerance

PTFE washers perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). This stability prevents them from becoming brittle in cryogenic applications or melting in high-heat situations, a range that far exceeds that of rubber or fiber.

The Lowest Coefficient of Friction

Known for its non-stick properties, PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating nature minimizes wear and tear in dynamic applications, extending the operational life of both the washer and the surrounding components.

Purity and Biocompatibility

PTFE is inherently non-contaminating and can be manufactured to meet stringent biocompatibility standards. This makes it an essential material in sensitive industries like food processing, pharmaceuticals, and medical devices, where material purity is non-negotiable.

Calculating the True Cost: Total Cost of Ownership

Focusing solely on the purchase price ignores the most significant expenses in any industrial operation: maintenance and downtime. This is where PTFE provides a clear return on investment.

Reduced Maintenance and Downtime

Because PTFE washers do not degrade from chemical or thermal stress, they require replacement far less frequently. Each avoided replacement cycle saves not only the cost of a new washer but also the significant labor costs and lost production from system downtime.

Extended Equipment Lifespan

A single PTFE washer can outlast multiple rubber or fiber washers in a demanding application. Over the life of a piece of equipment, the cumulative cost of repeatedly buying and installing cheaper, failing washers can easily exceed the one-time cost of a PTFE component.

Preventing Catastrophic Failure

In critical systems, a seal failure is not an inconvenience; it is a significant operational risk. The cost of a leak—including product loss, environmental cleanup, and potential damage to expensive equipment—dwarfs the initial cost difference of a high-performance washer.

Understanding the Trade-offs and Requirements

While PTFE is a superior material, objectivity requires acknowledging its specific needs and limitations to ensure it is the right choice.

The Upfront Investment

The most obvious trade-off is the higher initial cost. For non-critical, room-temperature applications with no chemical exposure, a less expensive material may be sufficient and more economical.

Surface Preparation is Critical

PTFE is a harder material than rubber and is less forgiving of surface imperfections. To achieve an optimal seal, PTFE washers require smooth, clean flange surfaces. Factoring in proper surface preparation during installation is crucial for leveraging the material's full sealing potential.

Making the Right Choice for Your Goal

Your application's specific demands will determine whether the investment in PTFE is justifiable.

- If your primary focus is minimizing upfront cost for a non-critical application: A standard rubber or fiber washer may be the most economical choice.

- If your primary focus is reliability in harsh chemical or extreme temperature environments: PTFE's durability makes it the most effective and safest long-term solution.

- If your primary focus is reducing system downtime and lifetime maintenance costs: PTFE's extended lifespan provides the lowest total cost of ownership and is the superior financial investment.

Ultimately, choosing PTFE is a strategic decision to invest in reliability and prevent the significant future costs of failure.

Summary Table:

| Factor | PTFE Washers | Common Alternatives (e.g., Rubber) |

|---|---|---|

| Initial Cost | Higher | Lower |

| Chemical Resistance | Excellent (Virtually inert) | Limited (Degrades over time) |

| Temperature Range | -200°C to +260°C | Narrower range |

| Lifespan | Long-lasting | Shorter, requires frequent replacement |

| Total Cost of Ownership | Lower (Due to reduced downtime & maintenance) | Higher (Due to frequent replacements & downtime) |

Ready to invest in reliability and reduce your long-term costs?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including washers, seals, liners, and labware. Our expertise ensures you get components that deliver superior performance in the most demanding environments—from semiconductor and medical applications to industrial and laboratory settings.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific needs. Don't let a short-term cost perspective lead to long-term expenses.

Contact us today to discuss how our PTFE solutions can enhance your operational efficiency and provide the lowest total cost of ownership!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some common industries and applications for PTFE/Teflon machined parts? Solve Harsh Environment Challenges

- What industries are particularly suited for PTFE with fillers? Enhance Performance in Demanding Applications

- What are the advantages of unreinforced PTFE laminates? Achieve Ultimate Signal Integrity for High-Frequency Designs

- What unique feature does the PTFE oil seal have for fluid retention? Active Hydrodynamic Sealing Explained

- What are the properties and uses of carbon-filled PTFE? Enhance Wear Resistance & Conductivity

- What type of sealing is used for the ball shaft in PTFE ball valves? Discover the Maintenance-Free V-Ring System

- How do the coefficients of friction compare between PTFE and graphite packing? PTFE Offers Lower Friction

- How are control valves customized for different processes? Tailor Performance for Your Application