The primary mechanical benefit of PTFE Teflon washers is their ability to create a reliable, long-lasting seal under high compressive loads without deforming. This unique combination of strength and flexibility, along with its exceptionally low friction, makes it invaluable in high-pressure systems like plumbing and hydraulics, where it also prevents wear on connecting parts.

The central takeaway is that while virgin PTFE is a relatively soft material, its mechanical strength is context-dependent. It excels under compression for sealing but requires reinforcement with fillers like glass or carbon to handle high tensile loads or abrasive conditions.

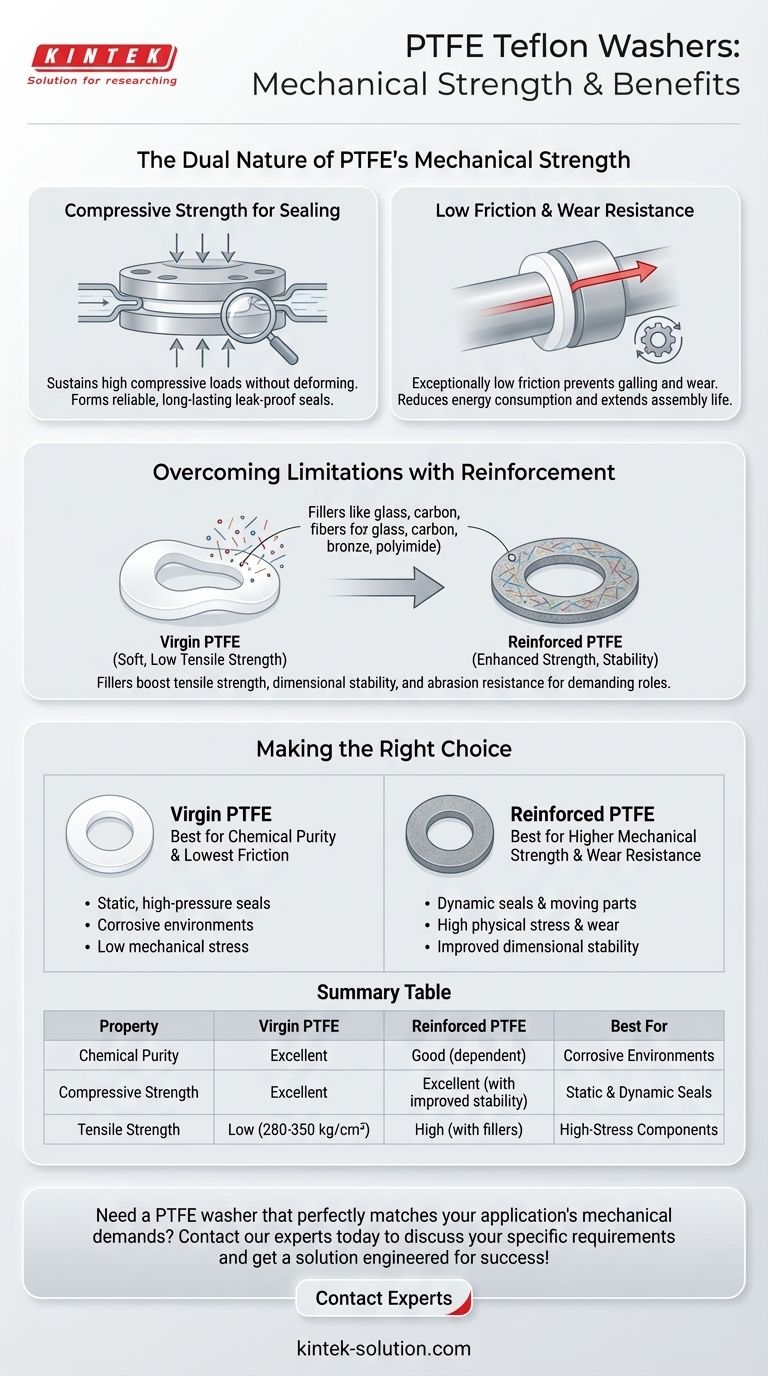

The Dual Nature of PTFE's Mechanical Strength

Understanding PTFE requires recognizing that it isn't "strong" in the same way metal is. Its value comes from a unique combination of properties that serve specific mechanical functions exceptionally well.

Compressive Strength for Sealing

PTFE's most significant mechanical advantage is its performance under compression. It is a lightweight yet resilient material that can sustain significant compressive forces without cracking or permanently deforming.

This makes it an ideal material for creating seals in high-pressure fluid and gas systems. The washer conforms to surface irregularities to form a tight barrier, preventing leaks.

Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material. This inherent lubricity is a powerful mechanical benefit in systems with moving or vibrating parts.

Using a PTFE washer prevents galling and wear on adjacent components, reducing energy consumption and dramatically extending the service life of the entire assembly.

Inherent Softness and Tensile Limits

It is crucial to acknowledge that virgin PTFE is a soft material. It has relatively low tensile strength (rated at 280-350 kg/cm²) and can be easily indented or scratched.

This softness is a limitation in applications where the washer is subjected to pulling forces (tension) or significant abrasion, as it may stretch or wear away.

Overcoming Limitations with Reinforcement

To overcome the inherent softness of virgin PTFE, manufacturers often enhance it with reinforcing additives, creating composite materials tailored for more demanding roles.

The Role of Fillers

Common fillers like glass fibers, carbon, bronze, or polyimide are blended with the raw PTFE resin.

These additives act as a structural matrix within the material, fundamentally changing its mechanical properties without sacrificing its core benefits like chemical resistance.

Enhanced Strength and Stability

Reinforcement significantly boosts the washer's performance. Fillers increase tensile strength, dimensional stability, and abrasion resistance.

This allows reinforced PTFE washers to be used in more demanding applications, such as dynamic seals or components that experience higher physical stress and wear.

Understanding the Trade-offs

Choosing the right type of PTFE washer requires balancing its strengths against its limitations for your specific application.

Virgin PTFE vs. Reinforced PTFE

Virgin PTFE is the best choice when chemical purity and the lowest possible friction are the top priorities. It is ideal for medical, food-grade, or highly corrosive environments with low mechanical stress.

Reinforced PTFE is necessary when higher mechanical strength, wear resistance, or dimensional stability under load is required. The trade-off is a slight increase in friction and a change in chemical compatibility depending on the filler.

Potential for Deformation (Creep)

Under sustained, heavy loads—especially at elevated temperatures—PTFE can be susceptible to "creep" or cold flow. This is a slow, gradual deformation of the material.

While its compressive strength is excellent for initial sealing, reinforcement with fillers like glass or carbon is critical for applications where the washer must maintain its precise dimensions under a constant, long-term load.

Making the Right Choice for Your Application

Selecting the correct PTFE washer is a matter of matching the material's properties to the mechanical demands of the system.

- If your primary focus is creating a leak-proof seal in a static, high-pressure system: Virgin PTFE's excellent compressive strength and conformability are often the ideal solution.

- If your primary focus is a dynamic application with moving parts and moderate loads: Reinforced PTFE is necessary to provide the required wear resistance and dimensional stability.

- If your primary focus is maximum chemical resistance in a low-stress environment: Virgin PTFE is the superior choice due to its inertness and purity.

By understanding this critical distinction between virgin and reinforced PTFE, you can leverage its unique mechanical advantages for your specific engineering goal.

Summary Table:

| Property | Virgin PTFE | Reinforced PTFE |

|---|---|---|

| Best For | Chemical purity, low friction | High strength, wear resistance |

| Compressive Strength | Excellent for sealing | Excellent, with improved stability |

| Tensile Strength | Low (280-350 kg/cm²) | High (with fillers like glass/carbon) |

| Key Applications | Static seals, corrosive environments | Dynamic seals, high-stress components |

Need a PTFE washer that perfectly matches your application's mechanical demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including seals and washers, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the chemical purity of virgin PTFE or the enhanced strength of a reinforced composite, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that delivers reliable performance and longevity.

Contact our experts today to discuss your specific requirements and get a solution engineered for success!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications