In essence, the ergonomic design of a PTFE shovel transforms it from a simple scoop into a precision instrument that directly benefits the user's physical well-being and task performance. Its primary advantages are a significant reduction in physical strain and enhanced user comfort, particularly during repetitive or prolonged laboratory work.

The core value of an ergonomic PTFE shovel extends beyond simple comfort. It represents a crucial intersection of user safety, operational efficiency, and data integrity by minimizing the physical fatigue that often leads to errors and injuries.

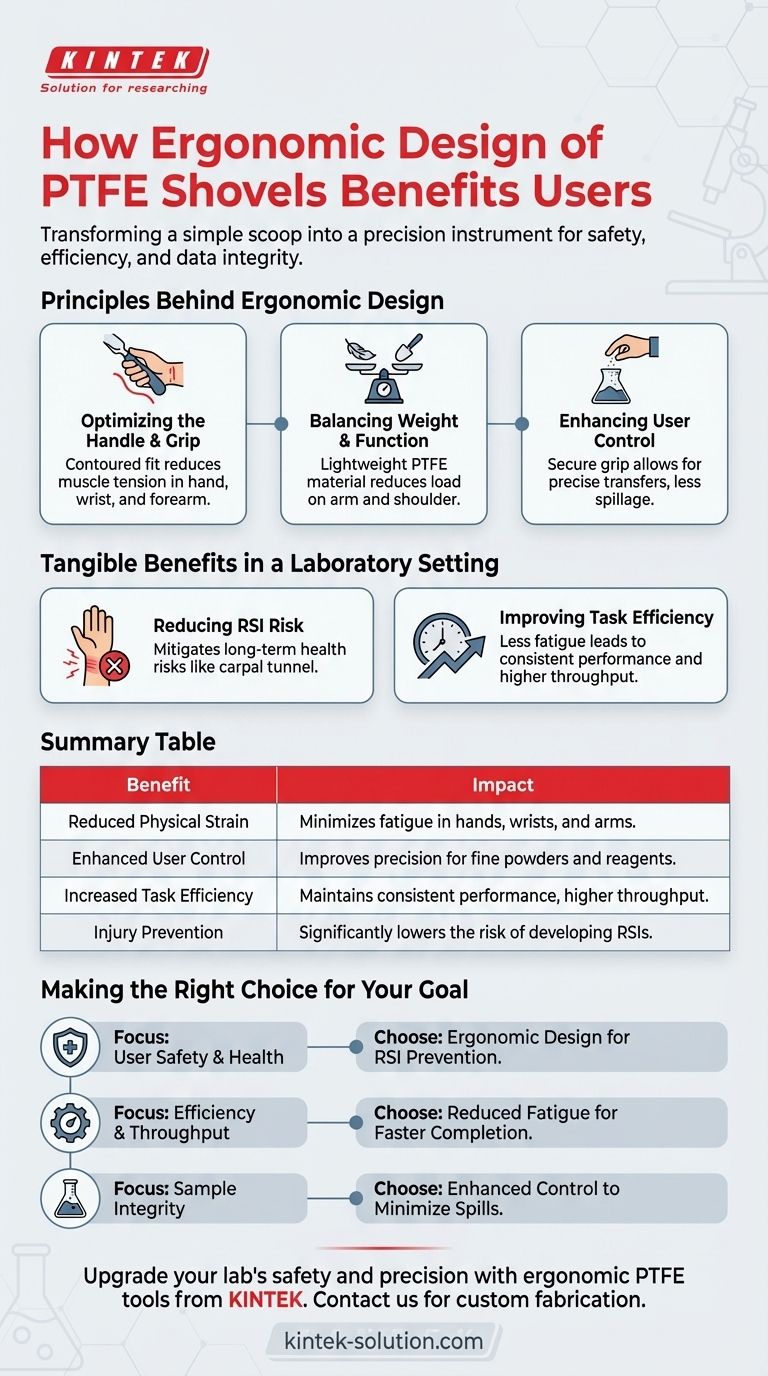

The Principles Behind Ergonomic Design

An effective ergonomic design is not an accident; it is a deliberate engineering choice. It focuses on how the tool interacts with the human body to optimize function and minimize stress.

Optimizing the Handle and Grip

The handle is the most critical ergonomic component. A well-designed handle is contoured to fit the natural curve of the hand, allowing for a secure grip with less muscle exertion.

This design reduces the tension required in the hand, wrist, and forearm, which is a primary cause of fatigue.

Balancing Weight and Function

Ergonomic shovels are engineered to be lightweight without sacrificing the structural integrity needed for their task. The use of a material like PTFE is key to achieving this balance.

A lighter tool reduces the load on the user's arm and shoulder, making repetitive motions feel significantly less strenuous over the course of a workday.

Enhancing User Control

A comfortable, secure grip translates directly to superior control over the shovel head. This is critical when handling fine powders, expensive reagents, or sensitive materials.

Better control means more precise transfers, less spillage, and a reduced risk of cross-contamination, directly impacting the quality of the work.

Tangible Benefits in a Laboratory Setting

The principles of ergonomic design deliver concrete advantages that can be observed and measured in any professional lab environment.

Reducing Risk of Repetitive Strain Injury (RSI)

Prolonged, repetitive scooping motions are a known risk factor for developing RSIs like carpal tunnel syndrome or tendonitis.

The reduced strain afforded by an ergonomic handle is the single most important factor in mitigating this long-term health risk for laboratory personnel.

Improving Task Efficiency

When a user experiences less fatigue, they can maintain a consistent level of performance for longer periods.

Tasks are completed more smoothly and with fewer pauses, leading to an overall increase in throughput and operational efficiency without compromising user well-being.

Understanding the Trade-offs

While highly beneficial, it's important to approach these specialized tools with a complete understanding of their context.

Cost Considerations

Ergonomically designed, specialized tools like PTFE shovels typically carry a higher initial purchase price than their non-ergonomic, generic counterparts.

This cost should be weighed against the long-term benefits of increased efficiency and reduced risk of workplace injury.

Specificity of Application

These shovels are purpose-built for scooping and transferring materials in a lab setting. Their design, while excellent for this task, is not intended for high-leverage or heavy-duty prying applications where a metal tool might be required.

Making the Right Choice for Your Goal

Selecting the right tool depends on prioritizing the challenges you aim to solve in your specific workflow.

- If your primary focus is user safety and long-term health: The investment in an ergonomic design is critical for preventing repetitive strain injuries in staff who perform frequent sampling tasks.

- If your primary focus is efficiency and throughput: The reduction in user fatigue directly supports more consistent and faster task completion over long shifts.

- If your primary focus is sample integrity: The enhanced control provided by a secure, ergonomic grip minimizes costly spills and the risk of cross-contamination.

Ultimately, choosing an ergonomically designed PTFE shovel is a strategic decision to invest in both human well-being and scientific accuracy.

Summary Table:

| Benefit | Impact |

|---|---|

| Reduced Physical Strain | Minimizes fatigue in hands, wrists, and arms during repetitive tasks. |

| Enhanced User Control | Improves precision for handling fine powders and expensive reagents. |

| Increased Task Efficiency | Maintains consistent performance, leading to higher throughput. |

| Injury Prevention | Significantly lowers the risk of developing Repetitive Strain Injuries (RSI). |

Upgrade your lab's safety and precision with ergonomic PTFE tools from KINTEK.

Our shovels are designed for professionals in the semiconductor, medical, and laboratory industries who demand both user comfort and sample integrity. We specialize in custom fabrication, from prototypes to high-volume orders, ensuring you get the perfect tool for your specific workflow.

Contact KINTEK today to discuss your requirements and experience the difference precision engineering makes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs