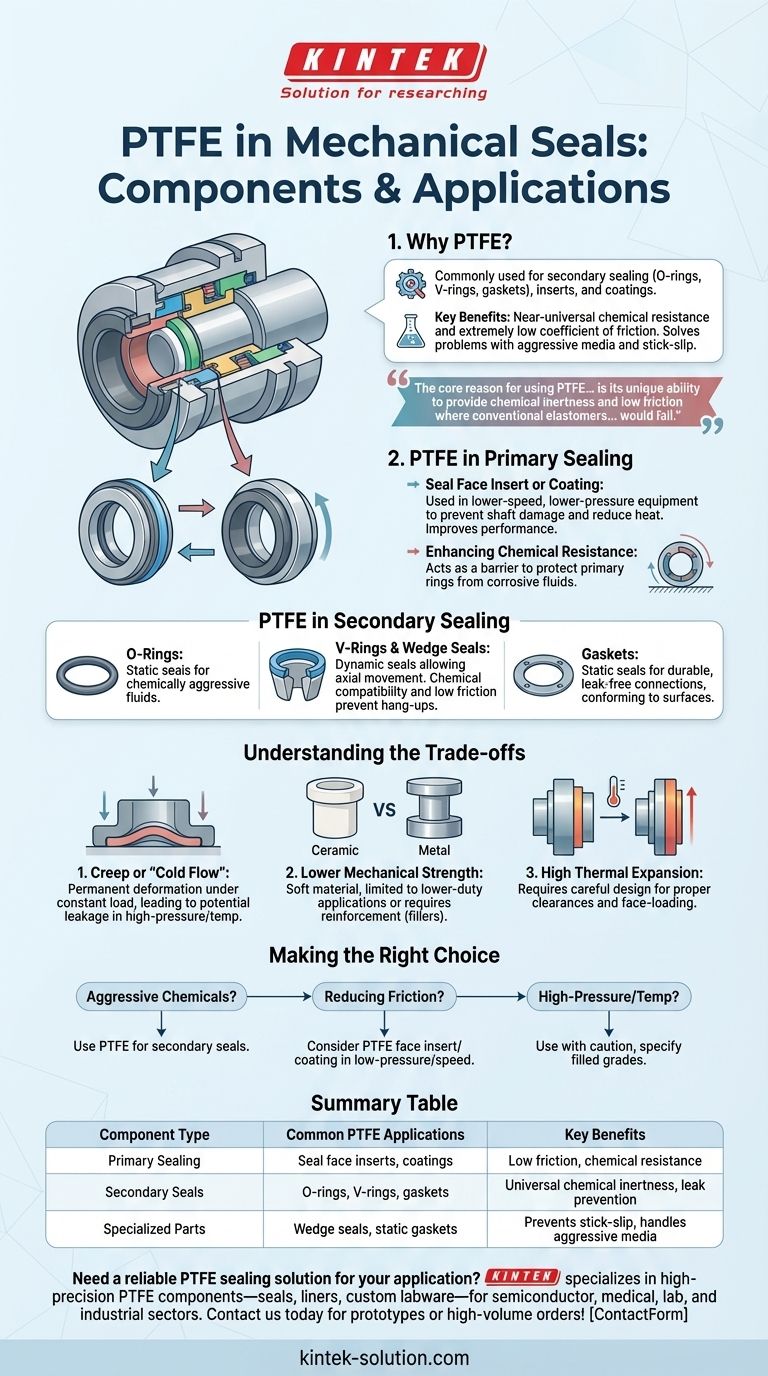

In a mechanical seal, PTFE is most commonly used for secondary sealing elements like O-rings, V-rings, and gaskets, as well as for inserts and coatings on primary seal faces. Its selection is driven by its near-universal chemical resistance and extremely low coefficient of friction, making it a problem-solver for aggressive media or applications where stick-slip is a concern.

The core reason for using PTFE in a mechanical seal is not for its strength, but for its unique ability to provide chemical inertness and low friction where conventional elastomers or other materials would fail.

The Role of PTFE in Primary Sealing

The primary seal is formed by two lapped faces, one rotating and one stationary. While not typically the main structural material for these faces, PTFE plays a critical specialized role.

As a Seal Face Insert or Coating

In certain applications, a PTFE insert is used as one of the primary seal faces. This is common in lower-speed, lower-pressure equipment where its low friction prevents shaft damage and reduces heat generation. It is also used as a coating to improve the performance of other components.

Enhancing Chemical Resistance

When a seal's primary rings are made of materials like carbon or silicon carbide, PTFE can be used as a chemically-resistant barrier. This protects less-resistant components of the seal assembly from corrosive or aggressive process fluids.

PTFE in Secondary Sealing Elements

Secondary seals are static or dynamic components that prevent leakage along the shaft and within the seal housing. This is where PTFE is most frequently employed.

O-Rings

PTFE O-rings are used as static seals between seal components. They are specified when the process fluid is too chemically aggressive for standard elastomers like Viton® or EPDM.

V-Rings and Wedge Seals

V-rings (or chevron packing) and wedges are dynamic secondary seals that allow for axial movement of the seal face. PTFE is the material of choice here due to its combination of chemical compatibility and low-friction "slipperiness," which prevents the seal from hanging up on the shaft.

Gaskets

PTFE is also used for static gaskets within the seal assembly, such as between the seal gland and the pump housing. Its ability to conform to surfaces while resisting chemical attack ensures a durable, leak-free connection.

Understanding the Trade-offs of Using PTFE

While highly effective, PTFE is a specialized material with clear limitations that must be respected in seal design.

Creep or "Cold Flow"

The most significant drawback of PTFE is its tendency to creep, or permanently deform over time when under a constant load. This can lead to a loss of sealing pressure and eventual leakage, especially in high-pressure or high-temperature applications.

Lower Mechanical Strength

Compared to ceramics, carbon, or metals, PTFE is a soft material. This limits its use as a primary seal face to lower-duty applications and is why it is often reinforced with fillers like glass, carbon, or bronze to improve its strength and wear resistance.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most other engineering materials. Seal designers must account for this to maintain proper clearances and face-loading across the operating temperature range.

Making the Right Choice for Your Goal

Selecting the right material is about matching its properties to the demands of the application.

- If your primary focus is sealing aggressive chemicals: Use PTFE for secondary seals like O-rings, wedges, and gaskets where elastomers would quickly degrade.

- If your primary focus is reducing friction or stick-slip: Consider PTFE as a seal face material or coating in low-pressure, low-speed applications.

- If your primary focus is high-pressure or high-temperature service: Use PTFE with caution, specifying a filled grade and ensuring the seal design mitigates the risk of cold flow.

Understanding where and why to use PTFE is key to designing and maintaining a robust and reliable mechanical seal.

Summary Table:

| Component Type | Common PTFE Applications | Key Benefits |

|---|---|---|

| Primary Sealing | Seal face inserts, coatings | Low friction, chemical resistance |

| Secondary Seals | O-rings, V-rings, gaskets | Universal chemical inertness, leak prevention |

| Specialized Parts | Wedge seals, static gaskets | Prevents stick-slip, handles aggressive media |

Need a reliable PTFE sealing solution for your application? KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, we deliver components that excel in chemical resistance and performance. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability