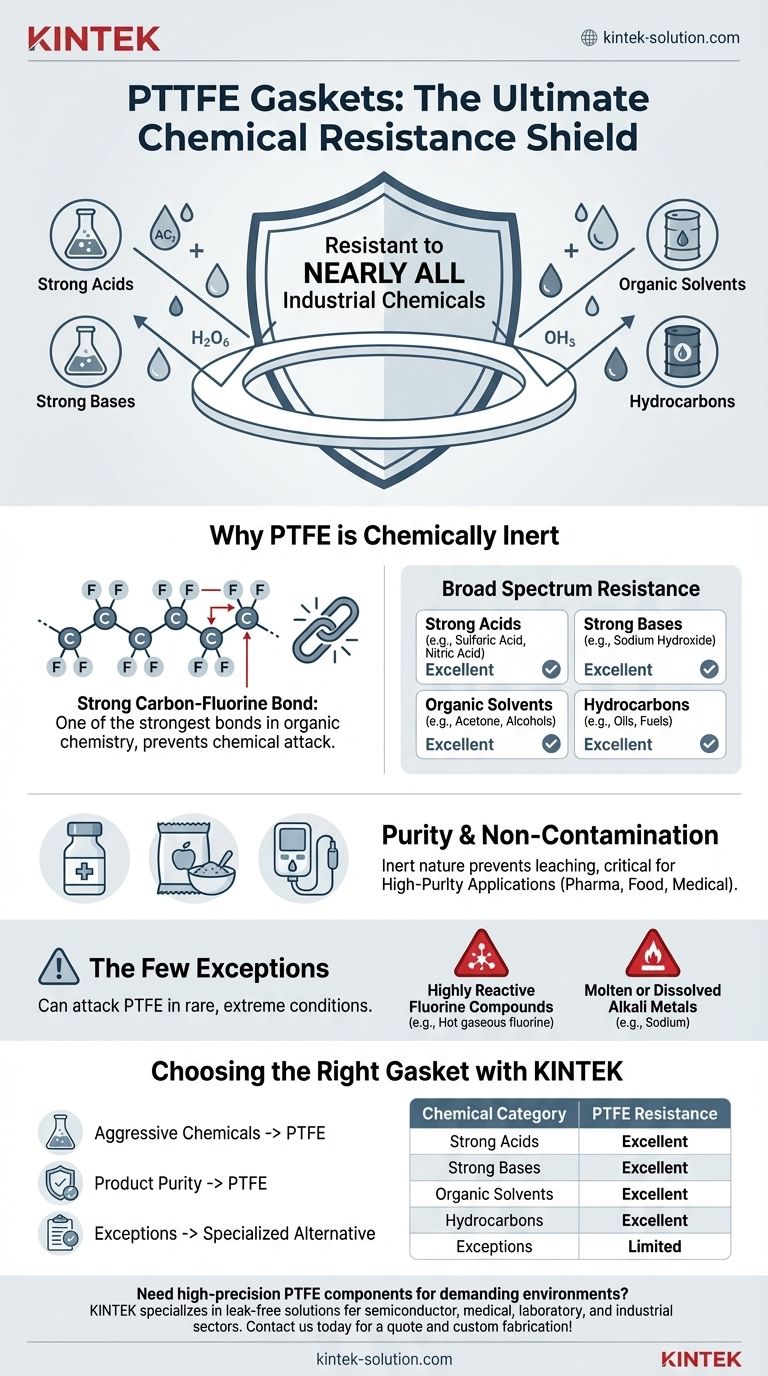

In short, PTFE gaskets are resistant to nearly all industrial chemicals. This includes a vast range of aggressive substances like concentrated acids, alkalis (bases), and organic solvents that would degrade most other materials. Its remarkable chemical inertness makes it a default choice for the most demanding sealing applications.

PTFE's chemical resistance is so comprehensive that it's often easier to define it by the very few, highly reactive chemicals that can attack it. For virtually all common industrial and laboratory applications, PTFE is considered universally compatible.

The Foundation of PTFE's Chemical Inertness

To understand why PTFE (Polytetrafluoroethylene) is so versatile, we need to look at its molecular structure. This foundational knowledge is key to trusting its performance in critical applications.

The Strength of the Carbon-Fluorine Bond

The core of PTFE's resilience lies in the powerful bonds between its carbon and fluorine atoms. This is one of the strongest single bonds in organic chemistry.

This molecular stability means that other chemicals lack the energy to break these bonds and react with the material. PTFE remains stable and does not dissolve in any known solvent at room temperature.

Broad Spectrum Resistance

Because of its inert chemical nature, PTFE is an excellent choice for sealing a wide array of media.

This includes strong acids like sulfuric and nitric acid, strong bases like sodium hydroxide, and virtually all solvents, hydrocarbons, and alcohols.

Purity and Non-Contamination

PTFE’s inertness also means it does not leach chemicals or contaminate the media it contacts.

This property is critical in high-purity applications such as pharmaceutical manufacturing, food processing, and medical device assembly, where preventing product contamination is paramount.

Understanding the Trade-offs: The Few Exceptions

While its resistance is nearly total, no material is perfect. A true technical understanding requires knowing the specific, and generally rare, conditions where PTFE is not suitable.

Highly Reactive Fluorine Compounds

PTFE can be attacked by a few exotic and highly aggressive chemicals.

These include hot gaseous fluorine, chlorine trifluoride, and oxygen difluoride. These substances are powerful enough to disrupt the stable carbon-fluorine structure.

Molten or Dissolved Alkali Metals

The other major exception is molten or dissolved alkali metals, such as sodium.

These metals are highly reactive and are one of the few chemical classes capable of corroding PTFE's surface. However, these are specialized conditions not found in most industrial processes.

Making the Right Choice for Your Goal

Your choice of gasket material should always align with the specific chemical environment and operational goals of your system.

- If your primary focus is handling aggressive acids, bases, or solvents: PTFE is one of the most reliable and safest sealing choices available for these common but challenging applications.

- If your primary focus is product purity and preventing contamination: PTFE's inherent inertness makes it the ideal material for applications in the food, pharmaceutical, and medical industries.

- If you are working with molten alkali metals or specific fluorine compounds: You must seek a specialized alternative, as these are the rare exceptions that fall outside of PTFE's capabilities.

Ultimately, understanding PTFE's near-universal chemical resistance and its specific, rare exceptions empowers you to select the right sealing material with confidence.

Summary Table:

| Chemical Category | PTFE Resistance | Common Examples |

|---|---|---|

| Strong Acids | Excellent | Sulfuric Acid, Nitric Acid, Hydrochloric Acid |

| Strong Bases (Alkalis) | Excellent | Sodium Hydroxide, Potassium Hydroxide |

| Organic Solvents | Excellent | Acetone, Toluene, Alcohols |

| Hydrocarbons | Excellent | Oils, Fuels, Greases |

| Exceptions | Limited | Molten Alkali Metals, Specific Fluorine Compounds |

Need a PTFE gasket that can handle your most aggressive chemicals?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, gaskets, liners, and labware. Our expertise ensures leak-free performance in the most demanding environments across the semiconductor, medical, laboratory, and industrial sectors.

Whether you require a standard solution or a custom-fabricated part—from prototypes to high-volume orders—we deliver the chemical resistance and purity your application demands.

Contact us today to discuss your specific chemical resistance requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments