In short, PTFE gaskets are essential in any industry where chemical resistance, product purity, or performance in extreme temperatures is non-negotiable. Their unique properties make them a cornerstone material in sectors ranging from chemical processing and pharmaceuticals to food and beverage, oil and gas, and aerospace.

The widespread use of PTFE gaskets is not a matter of preference, but of necessity. Their unmatched ability to resist aggressive chemicals and maintain purity makes them the default choice for critical applications where seal failure could lead to contamination, safety hazards, or catastrophic equipment damage.

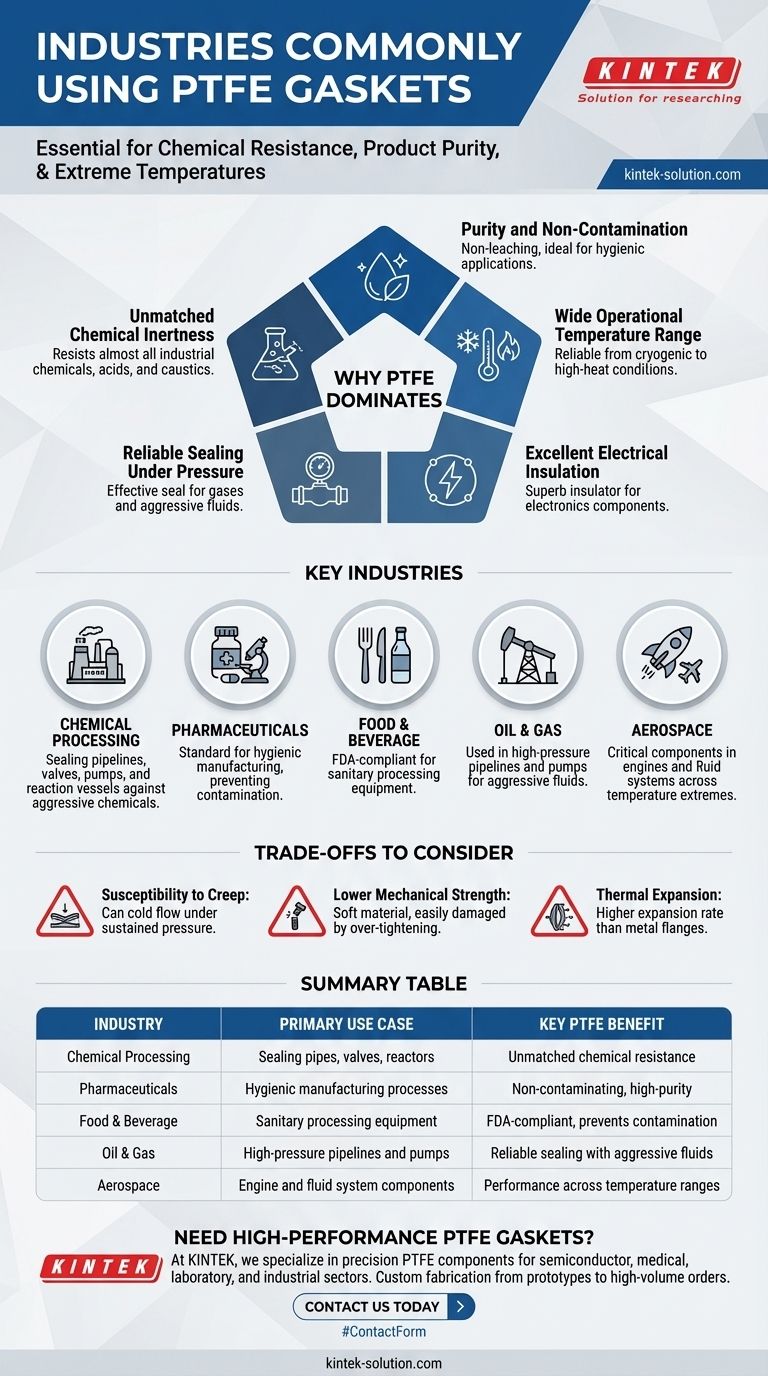

Why PTFE Dominates in Demanding Sectors

The value of a Polytetrafluoroethylene (PTFE) gasket lies in its fundamental material properties. These characteristics directly solve the most pressing challenges faced by engineers and operators in highly regulated and harsh industrial environments.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and caustics. This makes it an ideal sealing material in environments where corrosive fluids are being processed or transported.

This property is the primary reason for its ubiquity in the petrochemical and chemical processing industries for sealing pipelines, valves, pumps, and reaction vessels.

Purity and Non-Contamination

PTFE is an exceptionally pure and clean material that does not leach or contaminate the media it contacts. This is a critical requirement for hygienic applications.

For this reason, it is the standard in pharmaceutical manufacturing and food and beverage processing, where preventing product contamination is paramount to ensuring safety and quality.

Wide Operational Temperature Range

PTFE gaskets perform reliably across an exceptionally broad temperature spectrum, maintaining their integrity in both cryogenic conditions and high-heat applications.

This versatility makes them suitable for demanding processes in power generation facilities and for critical components in the aerospace industry, from engines to fluid systems.

Reliable Sealing Under Pressure

While pure PTFE has limitations, its ability to conform to sealing surfaces creates a highly effective and reliable seal, especially in applications involving gases and aggressive fluids.

This makes it a trusted solution in oil and gas operations for high-pressure pipelines and in industrial mechanical equipment like compressors and pumps.

Excellent Electrical Insulation

PTFE is also a superb electrical insulator. This property, combined with its temperature and chemical resistance, makes it a valuable material for sealing and insulating components in the electronics industry.

Understanding the Trade-offs

While PTFE is a superior material, it is not universally perfect. Acknowledging its limitations is key to using it effectively and preventing seal failure.

Susceptibility to Creep

The most significant limitation of PTFE is its tendency to "creep" or "cold flow." Under sustained pressure, especially at elevated temperatures, the material can slowly deform and move out of the flange, potentially leading to a loss of sealing pressure.

Lower Mechanical Strength

PTFE is a relatively soft material. It can be easily damaged by over-tightening during installation, which can compromise the seal's integrity from the start.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than the metal flanges it typically seals. This means it expands and contracts more with temperature changes, a factor that must be considered in applications with significant thermal cycling.

Making the Right Choice for Your Goal

Selecting a gasket material requires matching its properties to the primary demands of your application.

- If your primary focus is product purity and hygiene: PTFE is the industry standard for pharmaceutical and food-grade applications due to its inert, non-contaminating nature.

- If your primary focus is resisting aggressive chemicals: PTFE's unparalleled chemical resistance makes it the safest and most reliable choice for chemical and petrochemical processing.

- If your primary focus is high mechanical stress or pressure cycling: Consider "filled" PTFE gaskets, which incorporate materials like glass or carbon to reduce creep and improve mechanical strength.

Ultimately, understanding the core strengths of PTFE allows you to leverage it for creating safe, pure, and reliable sealed systems.

Summary Table:

| Industry | Primary Use Case | Key PTFE Benefit |

|---|---|---|

| Chemical Processing | Sealing pipes, valves, reactors | Unmatched chemical resistance to acids and caustics |

| Pharmaceuticals | Hygienic manufacturing processes | Non-contaminating, high-purity material |

| Food & Beverage | Sanitary processing equipment | FDA-compliant, prevents product contamination |

| Oil & Gas | High-pressure pipelines and pumps | Reliable sealing with aggressive fluids and gases |

| Aerospace | Engine and fluid system components | Performance across extreme temperature ranges |

Need high-performance PTFE gaskets for your critical applications?

At KINTEK, we specialize in manufacturing precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact sealing solution your operation demands.

Contact us today to discuss your specific requirements and discover how our PTFE components can enhance the safety, purity, and reliability of your sealed systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials