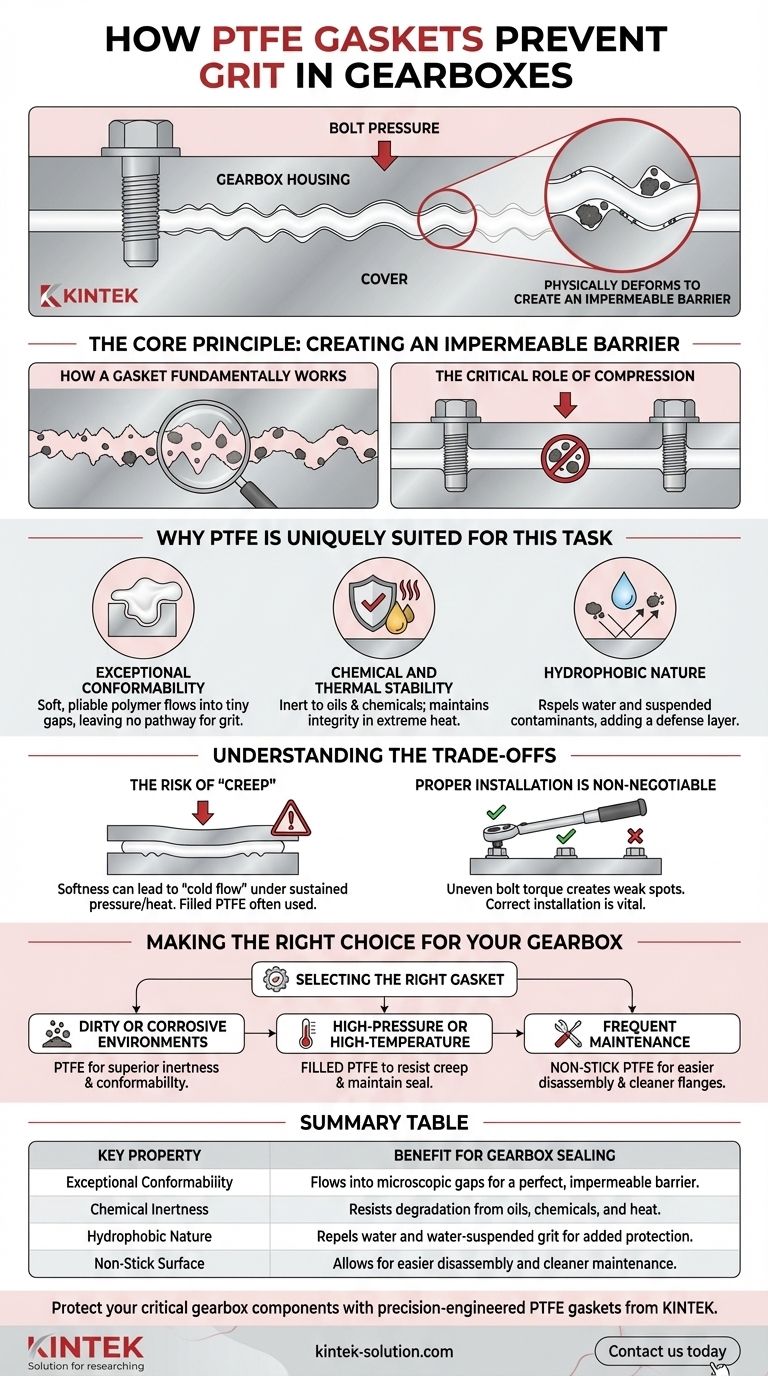

At its core, a PTFE gasket prevents grit from entering a gearbox by physically deforming under pressure to fill the microscopic imperfections between two mating surfaces. When the gearbox cover is bolted to the housing, the soft, pliable PTFE material flows into every tiny gap, creating a solid, continuous, and impermeable barrier that solid contaminants like grit and dust cannot penetrate.

The real challenge isn't just stopping grit at a single moment, but maintaining a perfect seal over time in harsh conditions. PTFE's effectiveness comes from a unique combination of physical conformability and chemical resilience, ensuring the barrier against contaminants doesn't degrade from heat, oil, or vibration.

The Core Principle: Creating an Impermeable Barrier

To understand why PTFE is so effective, we first need to look at how any gasket functions. The goal is to create a perfect seal between two imperfect surfaces.

How a Gasket Fundamentally Works

No matter how well-machined, the metal surfaces of a gearbox housing and its access cover have microscopic peaks and valleys.

When these two surfaces are pressed together, these tiny gaps create pathways for contaminants like grit, dust, and moisture to enter. A gasket is a piece of softer material placed between these surfaces.

The Critical Role of Compression

When the bolts are tightened, the gasket material is compressed. This force causes the material to flow and deform, filling every valley and gap.

This creates a complete, unbroken seal, transforming an imperfect metal-to-metal connection into a single, sealed unit. Grit is physically blocked from finding any path to the sensitive gears and bearings inside.

Why PTFE Is Uniquely Suited for This Task

While many materials can be compressed to form a seal, PTFE (Polytetrafluoroethylene) has a set of properties that make it exceptionally reliable for protecting gearboxes in demanding environments.

Exceptional Conformability

PTFE is a soft, pliable polymer. It requires relatively little bolt pressure to deform and create an effective seal.

This high degree of "flow" ensures it creates an extremely detailed impression of the metal surfaces, leaving virtually no pathway for even the smallest particles of grit to squeeze through.

Chemical and Thermal Stability

A gearbox environment is hostile. The seal is constantly exposed to lubricating oils, heat, and potentially external chemicals.

PTFE is almost completely chemically inert. It will not swell, harden, or degrade when exposed to gearbox oils or industrial contaminants. It also maintains its integrity across a wide temperature range, ensuring the seal remains effective whether the gearbox is cold or at peak operating temperature.

Hydrophobic Nature

PTFE naturally repels water. This property, known as being hydrophobic, helps prevent moisture from being drawn into the sealing interface.

By keeping water out, it also keeps out the fine grit and contaminants that are often suspended in it, providing another layer of defense for the internal components.

Understanding the Trade-offs

No material is perfect. While PTFE is an excellent choice for sealing, it's critical to understand its limitations to ensure proper application and reliability.

The Risk of "Creep"

The very softness that makes PTFE conform so well can also be a weakness. Under sustained pressure and high temperatures, pure PTFE can slowly deform over time, a phenomenon known as creep or cold flow.

This can cause the bolts to lose their clamping force, potentially compromising the seal. For this reason, filled PTFE gaskets (mixed with materials like glass or carbon) are often used to increase rigidity and resistance to creep in more demanding applications.

Proper Installation is Non-Negotiable

The effectiveness of any gasket, including PTFE, is highly dependent on correct installation.

Uneven or improper bolt torque can create high and low-pressure spots across the gasket. This can either crush the material or leave insufficient pressure to form a proper seal, creating an entry point for the very grit you're trying to block.

Making the Right Choice for Your Gearbox

Selecting the right gasket requires matching the material's properties to the operational demands and environment of the equipment.

- If your primary focus is operating in extremely dirty or corrosive environments: PTFE's superior chemical inertness and conformability provide the most reliable long-term barrier against contamination.

- If your primary focus is managing high-pressure or high-temperature applications: Ensure you are using a filled PTFE grade specifically engineered to resist creep and maintain sealing pressure under stress.

- If your primary focus is frequent maintenance and accessibility: The non-stick nature of PTFE allows for easier disassembly and cleaner flange surfaces, reducing labor and downtime during service.

Ultimately, choosing a PTFE gasket is an investment in protecting the precise, sensitive components at the heart of your machinery.

Summary Table:

| Key Property | Benefit for Gearbox Sealing |

|---|---|

| Exceptional Conformability | Flows into microscopic gaps to create a perfect, impermeable barrier. |

| Chemical Inertness | Resists degradation from oils, chemicals, and heat, maintaining seal integrity. |

| Hydrophobic Nature | Repels water and water-suspended grit for added protection. |

| Non-Stick Surface | Allows for easier disassembly and cleaner maintenance. |

Protect your critical gearbox components with precision-engineered PTFE gaskets from KINTEK.

Whether you operate in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom PTFE fabrication ensures you get a seal perfectly matched to your application's demands—from prototypes to high-volume orders. We prioritize precision production to deliver components that guarantee reliability and reduce downtime.

Contact us today to discuss your specific sealing challenges and discover how KINTEK's PTFE solutions can enhance your equipment's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance