To select the right PTFE gasket material, you must look beyond the base polymer and evaluate its physical construction against your specific operational conditions. The key factors are the material’s chemical compatibility with your media, its ability to withstand the combined pressure and temperature (Pr value), and whether its form—such as skived, expanded, or structured—is engineered to resist deformation under load.

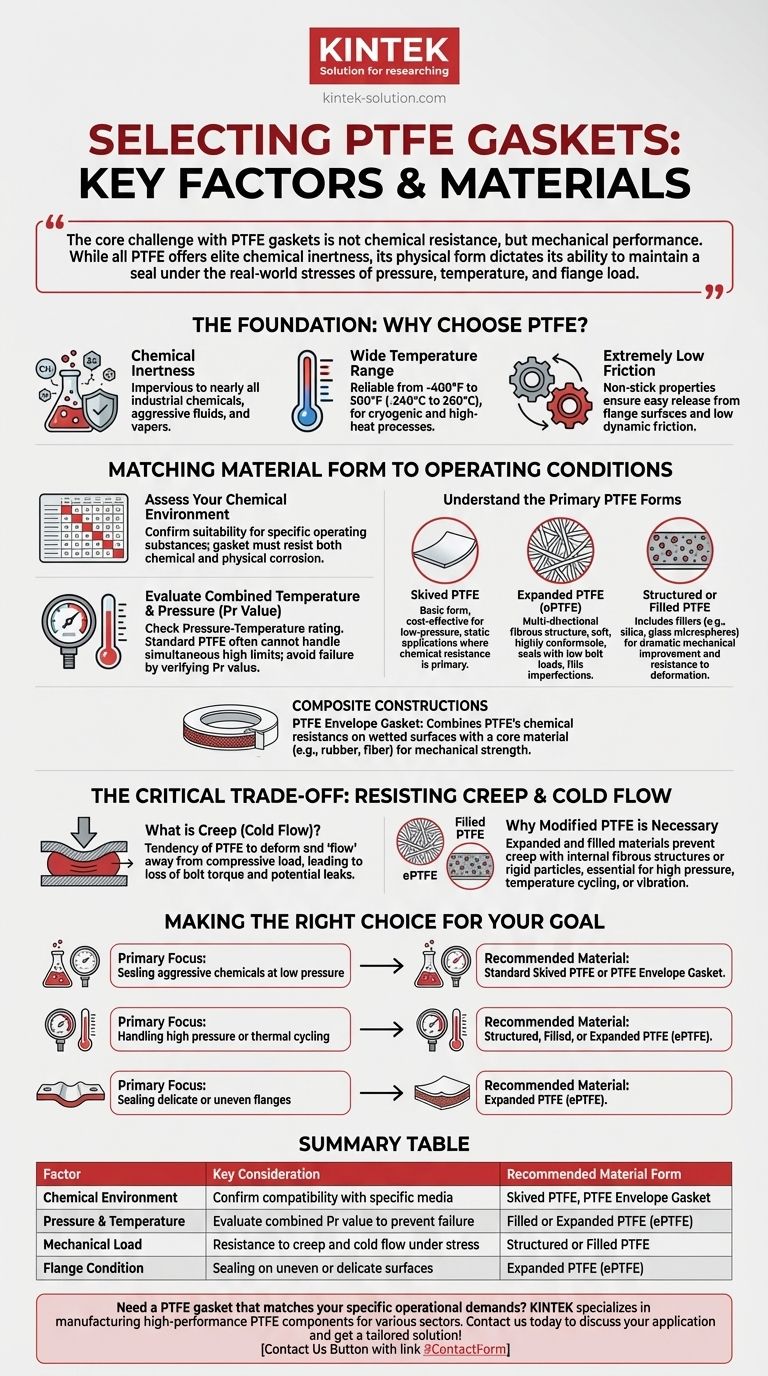

The core challenge with PTFE gaskets is not chemical resistance, but mechanical performance. While all PTFE offers elite chemical inertness, its physical form dictates its ability to maintain a seal under the real-world stresses of pressure, temperature, and flange load.

The Foundation: Why Choose PTFE?

Before comparing different types of PTFE, it's essential to understand the inherent strengths of the base material. These properties are why PTFE is a go-to choice for demanding sealing applications.

Unmatched Chemical Inertness

Polytetrafluoroethylene (PTFE) is one of the most chemically resistant materials available. Its non-reactive characteristics make it impervious to degradation from nearly all industrial chemicals, aggressive fluids, and vapors.

Wide Operational Temperature Range

PTFE performs reliably across an exceptionally broad temperature spectrum, typically from -400°F to 500°F (-240°C to 260°C). This makes it suitable for both cryogenic and high-heat processes.

Extremely Low Friction

The material has a very low coefficient of friction, which is beneficial in applications with any dynamic component or where easy release is required. It ensures that the gasket will not stick to flange surfaces.

Matching Material Form to Operating Conditions

The term "PTFE gasket" can refer to several distinct material constructions. Choosing the correct one requires a clear understanding of your application's mechanical and chemical demands.

Assess Your Chemical Environment

While PTFE is broadly resistant, you must confirm its suitability for your specific operating substance. The gasket must resist both chemical and physical corrosion to ensure a long service life.

For highly aggressive media, verifying compatibility is a critical first step, as certain rare, highly reactive chemicals can still pose a challenge.

Evaluate Combined Temperature and Pressure

A gasket's performance is dictated by its Pressure-Temperature rating, often called a Pr value. Most standard PTFE gaskets cannot simultaneously handle the upper limits of both high temperature and high pressure.

You must evaluate the gasket's specifications against your system's peak operating conditions to prevent failure.

Understand the Primary PTFE Forms

The "raw material" is often processed into different forms to enhance specific mechanical properties.

-

Skived PTFE: This is the most basic form, created by shaving a thin sheet from a larger billet. It is cost-effective and suitable for general use in low-pressure, static applications where its chemical resistance is the primary need.

-

Expanded PTFE (ePTFE): This material is engineered with a multi-directional fibrous structure. This expansion process creates a soft, highly conformable material that provides an excellent seal with low bolt loads and can fill in flange imperfections.

-

Structured or Filled PTFE: These gaskets include a filler material (like silica, glass microspheres, or barium sulfate) within the PTFE matrix. The filler dramatically improves the gasket's mechanical properties, especially its resistance to deformation.

Consider Composite Constructions

A PTFE envelope gasket combines the best of both worlds. It features a core material (like rubber or a non-asbestos fiber) wrapped in a thin, protective layer of PTFE.

This design uses the PTFE for its chemical resistance on all wetted surfaces while relying on the core material to provide mechanical strength and resilience.

The Critical Trade-off: Resisting Creep and Cold Flow

The single most important factor that distinguishes different PTFE gasket materials is their ability to resist deformation. This is the primary weakness of pure, unprocessed PTFE.

What is Creep (Cold Flow)?

Creep, also known as cold flow, is the tendency of PTFE to deform and "flow" away from a compressive load over time. When a flange is tightened, a pure PTFE gasket can slowly thin out, causing a loss of bolt torque and a potential leak.

Why Modified PTFE is Often Necessary

Expanded and filled PTFE materials were developed specifically to combat creep. The internal fibrous structure of ePTFE and the rigid particles in filled PTFE provide a stable backbone that prevents the material from flowing under pressure.

This makes them far more reliable in applications involving high pressure, temperature cycling, or significant vibration.

Making the Right Choice for Your Goal

Your final decision should be guided by the most critical demand of your application.

- If your primary focus is sealing aggressive chemicals at low pressure: A standard skived PTFE or a PTFE envelope gasket offers a cost-effective and reliable solution.

- If your primary focus is handling high pressure or thermal cycling: You must use a structured, filled, or expanded PTFE gasket designed to resist creep and maintain bolt load.

- If your primary focus is sealing delicate or uneven flanges: The soft, conformable nature of expanded PTFE (ePTFE) will provide the best seal with the lowest required bolt force.

Choosing the right gasket means matching the material's mechanical capabilities to the physical forces of your system.

Summary Table:

| Factor | Key Consideration | Recommended Material Form |

|---|---|---|

| Chemical Environment | Confirm compatibility with specific media | Skived PTFE, PTFE Envelope Gasket |

| Pressure & Temperature | Evaluate combined Pr value to prevent failure | Filled or Expanded PTFE (ePTFE) |

| Mechanical Load | Resistance to creep and cold flow under stress | Structured or Filled PTFE |

| Flange Condition | Sealing on uneven or delicate surfaces | Expanded PTFE (ePTFE) |

Need a PTFE gasket that matches your specific operational demands? KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our precision production ensures reliable performance under extreme conditions. Contact us today to discuss your application and get a tailored solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability