At its core, Polytetrafluoroethylene (PTFE) possesses one of the widest operating temperature ranges of any polymer. It maintains its critical properties in conditions from deep cryogenic freezing to high industrial heat, making it exceptionally versatile. For practical engineering purposes, PTFE can be used continuously at temperatures up to 260°C (500°F) and remains strong and tough at temperatures as low as -268°C (-450°F).

The true value of PTFE isn't just its ability to survive extreme temperatures, but its capacity to maintain excellent mechanical and chemical properties across that entire range, ensuring consistent and reliable performance where other materials would fail.

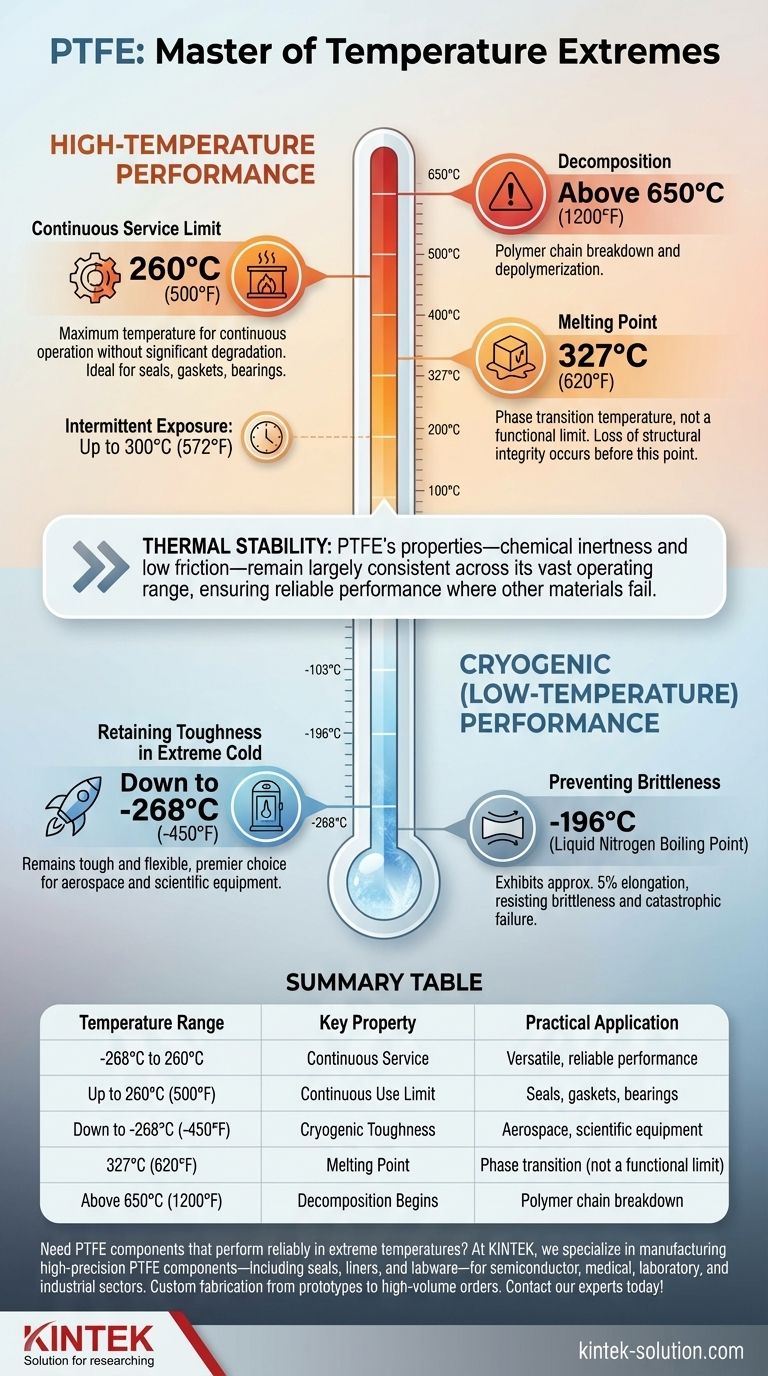

High-Temperature Performance

PTFE's behavior at high temperatures is defined by several key thresholds. Understanding the difference between its continuous service temperature, melting point, and decomposition temperature is critical for safe and effective application.

The Continuous Service Limit

The most important figure for engineers is the continuous service temperature, which for PTFE is 260°C (500°F). This is the maximum temperature at which the material can operate for extended periods without significant degradation of its properties.

Some grades can handle brief, intermittent exposure to temperatures as high as 300°C (572°F), but this should not be considered a standard operating limit.

The Melting Point

PTFE has a high melting point, typically around 327°C (620°F). This is a phase transition temperature, not a functional limit. Well before it reaches this point, the material will have lost most of its structural integrity and mechanical strength.

Decomposition

At extremely high temperatures, far above its melting point, PTFE does not burn but undergoes depolymerization. This process begins to occur at temperatures above 650°C (1200°F), where the polymer chain breaks down.

Cryogenic (Low-Temperature) Performance

Many materials become extremely brittle and fracture easily at very low temperatures. PTFE is a notable exception, making it a premier choice for cryogenic applications.

Retaining Toughness in Extreme Cold

PTFE remains remarkably tough and flexible even at temperatures approaching absolute zero. It can withstand temperatures down to approximately -268°C (-450°F).

Preventing Brittleness

Even at a temperature of -196°C (the boiling point of liquid nitrogen), PTFE still exhibits around 5% elongation. This demonstrates its ability to resist the brittleness that causes catastrophic failure in most other plastics under cryogenic conditions. This makes it invaluable for components in aerospace and scientific equipment.

Understanding the Practical Limits

Simply knowing the temperature range is not enough. To use PTFE effectively, you must understand the practical implications of these limits.

Service Temperature is Not Melting Point

A common mistake is to conflate the melting point with the maximum service temperature. The material's useful properties decline significantly as it approaches its melting point. Always design for the continuous service temperature of 260°C for any application requiring long-term reliability.

Thermal Stability is Key

PTFE's primary advantage is its thermal stability. This means its properties—such as chemical inertness and low friction—remain largely consistent across its vast operating temperature range. This predictability is essential for high-performance components in aerospace, automotive, and industrial machinery.

Application Determines the Limit

The specific grade of PTFE and the demands of the application will dictate the true thermal limits. For a coating on an industrial oven part, the high-temperature limit is paramount. For a seal in a liquid hydrogen fuel system, its toughness at cryogenic temperatures is the critical factor.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE's thermal profile meets your project's needs.

- If your primary focus is high-heat industrial use: Rely on the continuous service temperature of 260°C (500°F) for designing durable parts like seals, gaskets, and bearings.

- If your primary focus is cryogenic performance: PTFE is an elite choice due to its ability to maintain toughness and flexibility down to -268°C (-450°F), preventing brittle failure.

- If your primary focus is environments with wide temperature swings: The exceptional stability of PTFE across its entire range ensures reliable and predictable performance where conditions fluctuate dramatically.

Ultimately, PTFE's remarkable thermal resistance makes it one of the most dependable and versatile polymers for extreme engineering challenges.

Summary Table:

| Temperature Range | Key Property | Practical Application |

|---|---|---|

| -268°C to 260°C | Continuous Service | Versatile, reliable performance |

| Up to 260°C (500°F) | Continuous Use Limit | Seals, gaskets, bearings |

| Down to -268°C (-450°F) | Cryogenic Toughness | Aerospace, scientific equipment |

| 327°C (620°F) | Melting Point | Phase transition (not a functional limit) |

| Above 650°C (1200°F) | Decomposition Begins | Polymer chain breakdown |

Need PTFE components that perform reliably in extreme temperatures?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts maintain critical mechanical and chemical properties from deep cryogenic conditions to high industrial heat.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability for your most demanding applications.

Contact our experts today to discuss how our PTFE solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the primary applications of PTFE? Unlocking High-Performance Solutions

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables