In scientific filtration, Polytetrafluoroethylene (PTFE) filters are the specialists for harsh conditions. They are the default choice for working with aggressive chemicals, organic solvents, and gases where sample purity is paramount. Common applications include preparing samples for chromatography (HPLC), sterile venting of containers and bioreactors, and filtering strong acids or bases that would destroy other filter materials.

The decision to use a PTFE filter is driven by its two defining properties: extreme chemical resistance and natural hydrophobicity. This makes it the go-to material for filtering aggressive organic liquids or sterilely venting air, applications where other filters would either degrade or allow unwanted aqueous contaminants to pass through.

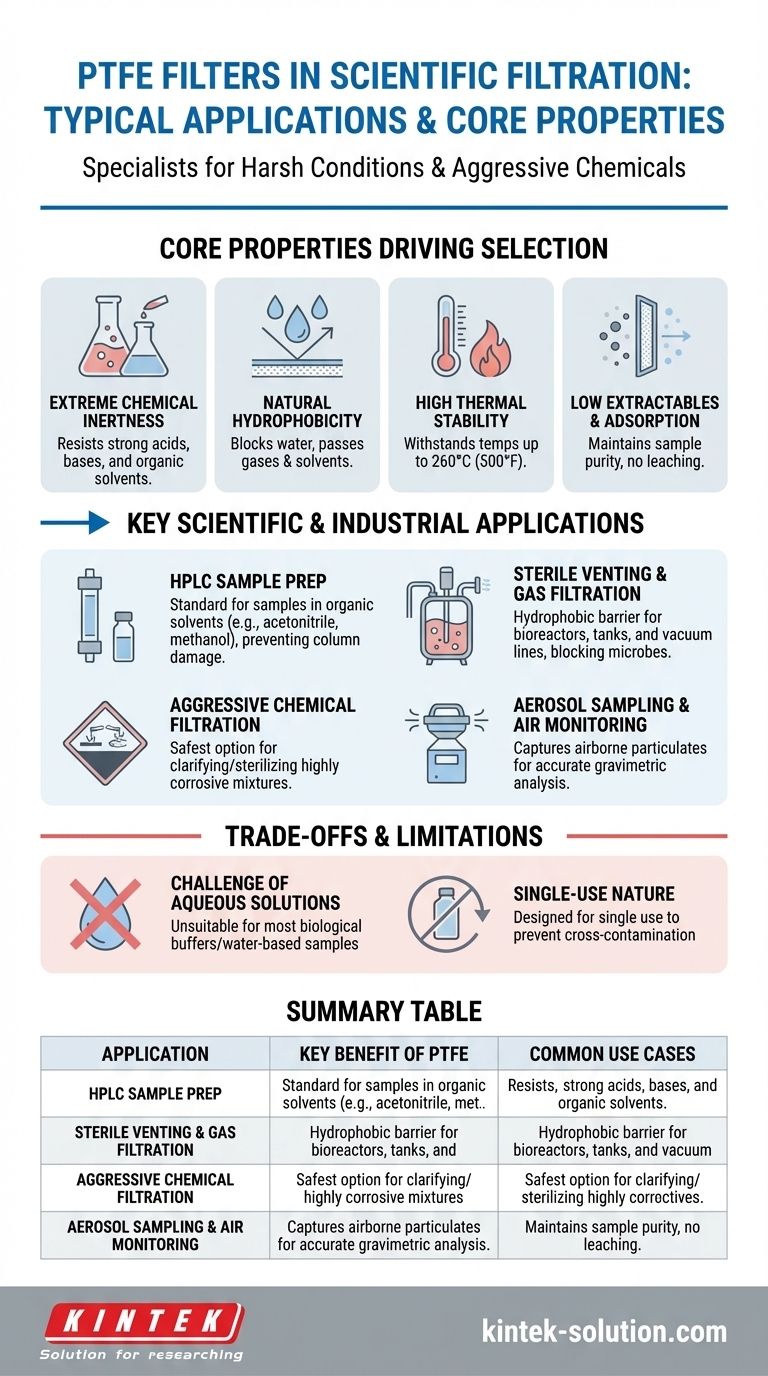

The Core Properties Driving PTFE Filter Selection

To understand where PTFE filters are used, you must first understand the fundamental material properties that make them suitable for specific tasks. These characteristics dictate their entire range of applications.

Extreme Chemical Inertness

PTFE is one of the most non-reactive substances known. It offers exceptional resistance to a vast range of chemicals, including strong acids, aggressive bases, and nearly all organic solvents.

This inertness ensures the filter itself does not break down, swell, or leach impurities into the sample being filtered. This is critical for maintaining the purity of the filtrate, especially in sensitive analytical techniques.

Natural Hydrophobicity

PTFE naturally repels water. This hydrophobic nature prevents aqueous solutions from passing through the membrane under normal pressure.

While this makes it unsuitable for filtering water-based samples directly, it is a significant advantage for applications like venting, gas filtration, and aerosol sampling, as it allows gases to pass freely while blocking moisture and aqueous contaminants.

High Thermal Stability

PTFE filters can withstand high temperatures, often up to 260°C (500°F). This makes them suitable for processes involving hot gases, air, or steam sterilization.

Low Extractables and Adsorption

A well-made PTFE filter contributes minimal foreign material (extractables) to the sample. It also exhibits very low protein binding.

This ensures that the chemical composition of your sample remains unchanged after filtration, a crucial requirement for accurate chemical analysis.

Key Scientific and Industrial Applications

Based on its core properties, PTFE is deployed in several critical filtration scenarios.

Preparing Samples for Chromatography (HPLC)

This is a primary application. When preparing samples dissolved in organic solvents for analysis by High-Performance Liquid Chromatography (HPLC), a PTFE filter is the standard choice.

Its resistance to solvents like acetonitrile, methanol, and others ensures that the filter doesn't degrade and introduce particles or chemical contaminants that could damage the expensive chromatography column and interfere with the results.

Sterile Venting and Gas Filtration

The hydrophobic nature of PTFE makes it an excellent barrier to aqueous microbes and aerosols while allowing sterile gas exchange.

PTFE vent filters are commonly used on fermentation tanks, bioreactors, sterile water containers, and vacuum pump lines to prevent contamination from entering while allowing pressure to equalize.

Filtering Aggressive Solvents and Chemicals

For any lab procedure that requires clarifying or sterilizing a highly corrosive chemical, PTFE is the safest option.

This includes filtering strong acids, bases, or other reactive mixtures that would quickly dissolve materials like nylon or cellulose.

Aerosol Sampling and Air Monitoring

PTFE filters are used in environmental science and industrial hygiene to capture airborne particulates.

Their chemical inertness and low tare mass allow for accurate gravimetric analysis (weighing) of the collected sample without interference from the filter media itself.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Understanding its limitations is key to using it correctly.

The Challenge of Aqueous Solutions

The most significant limitation is PTFE's hydrophobicity. It will not allow water or primarily aqueous solutions to pass through without applying very high pressure.

Because of this, standard PTFE filters are completely unsuitable for filtering most biological buffers or water-based samples. For these applications, you must use a hydrophilic filter (like PES, PVDF, or nylon) or a specially treated hydrophilic PTFE membrane.

Single-Use Nature

Most PTFE syringe filters and membranes are designed for single use. Attempting to clean and reuse them can compromise their integrity and lead to cross-contamination, making them a recurring cost.

Mechanical Properties

Compared to some other polymers, PTFE is softer and has lower tensile strength. While this is rarely an issue in a properly supported filter housing, the membrane must be handled with care to avoid punctures or tears.

Making the Right Choice for Your Application

Ultimately, your filtration goal determines the correct material.

- If your primary focus is filtering aggressive organic solvents or strong acids: PTFE is your safest and most reliable choice due to its unparalleled chemical inertness.

- If your primary focus is sterile venting or gas/air filtration: The natural hydrophobicity of PTFE makes it ideal for preventing moisture and microbial contamination from entering your system.

- If your primary focus is filtering aqueous (water-based) solutions: You should avoid standard PTFE and instead choose a hydrophilic filter material like nylon, PES, or a hydrophilic-treated PTFE.

Understanding these core principles empowers you to select the right filter based on chemical compatibility and application needs, ensuring the integrity of your work.

Summary Table:

| Application | Key Benefit of PTFE | Common Use Cases |

|---|---|---|

| HPLC Sample Prep | Resists degradation by organic solvents | Filtering samples in acetonitrile or methanol for analysis |

| Sterile Venting | Hydrophobic barrier blocks microbes | Venting bioreactors, fermentation tanks, and sterile containers |

| Aggressive Chemical Filtration | Inert to strong acids, bases, and solvents | Clarifying or sterilizing corrosive liquids without contamination |

| Gas Filtration & Aerosol Sampling | Allows gas flow while blocking moisture | Air monitoring, vacuum pump protection, and environmental sampling |

Need a reliable PTFE filter for your demanding application?

At KINTEK, we specialize in manufacturing high-purity PTFE components, including custom filters, seals, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production ensures your filters deliver unmatched chemical resistance and performance—from prototypes to high-volume orders.

Contact us today to discuss your specific filtration challenges and get a custom solution that protects your samples and processes.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE preferred over glass in certain labware applications? Achieve Superior Resilience for Harsh Conditions

- In which industries are PTFE lined caps commonly used? Ensure Product Purity & Chemical Resistance

- How does the durability of PTFE vials contribute to cost savings? Lower Your Lab's Total Cost of Ownership

- How do Teflon membranes contribute to the accuracy and reliability of laboratory experiments? Ensure Purity and Precision

- What are the temperature limits for the PTFE bottle? Ensure Safety from -200°C to 260°C

- What are the primary uses of PTFE filters? Achieve Pure, Sterile Filtration for Aggressive Chemicals

- What overall role do PTFE/silicone septa play in HPLC workflows? Protect Sample Integrity for Accurate Results

- What are the primary uses of PTFE silicone septa? Ensure Sample Integrity in GC/LC Analysis