The fundamental benefit of PTFE's hydrophobicity is its ability to prevent water and ambient moisture from blocking the filter's pores. This ensures consistent, reliable performance in applications involving gases, air, aggressive solvents, and acids, where a water-saturated (or "wet-out") filter would fail.

The core value of a PTFE filter's water-repelling nature is not simply an abstract property; it is the key to its reliability. This hydrophobicity guarantees that air and specific liquids can pass through freely, even in high-humidity environments that would render other filters useless.

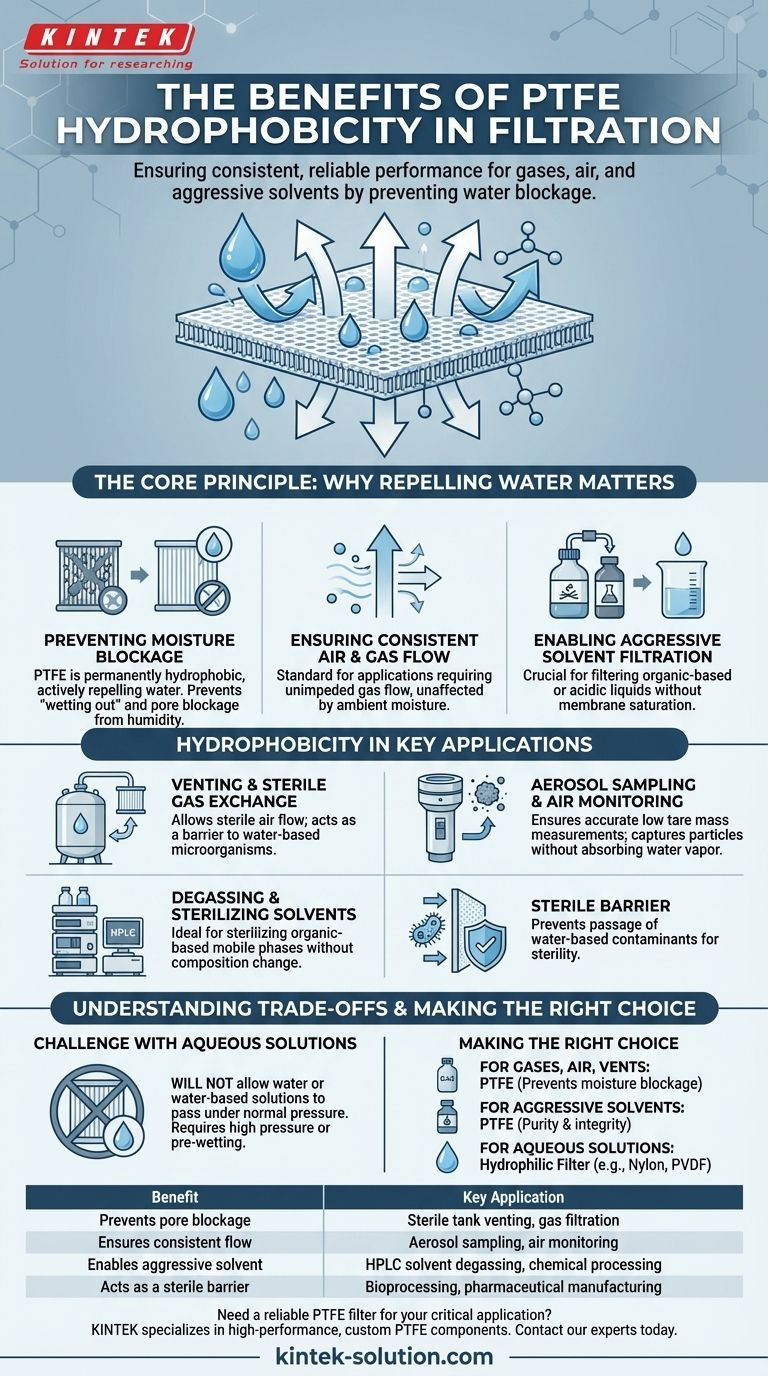

The Core Principle: Why Repelling Water Matters

A filter's job is to allow certain substances to pass through while blocking others. When a filter membrane becomes saturated with a liquid it wasn't designed for, its performance is compromised.

Preventing Moisture Blockage

Unlike hydrophilic filters that readily absorb water, PTFE membranes are permanently hydrophobic. They actively repel water molecules.

This means they will not become clogged by humidity in the air or by trace amounts of water in a sample. This phenomenon, known as "wetting out," can completely block airflow in a hydrophilic filter.

Ensuring Consistent Air and Gas Flow

Because PTFE filters do not get wet from ambient moisture, they are the standard for applications that demand unimpeded gas flow.

This makes them exceptionally reliable for sterile venting, sampling airborne particles, and filtering high-purity gases without pressure fluctuations or blockages.

Enabling Aggressive Solvent Filtration

While PTFE's renowned chemical inertness is critical for filtering aggressive solvents, its hydrophobicity is equally important.

It ensures that organic-based or highly acidic liquids can be filtered without the membrane becoming saturated by any residual aqueous content, preserving the purity of the filtrate.

Hydrophobicity in Key Applications

The theoretical benefit of repelling water translates directly into superior performance in several critical industrial and laboratory settings.

Venting and Sterile Gas Exchange

PTFE filters are essential for applications like protecting the contents of a fermentation tank or sterile container.

They allow sterile air to move in and out to equalize pressure while their hydrophobic surface prevents water-based microorganisms and contaminants from entering, effectively acting as a sterile barrier.

Aerosol Sampling and Air Monitoring

When measuring airborne particulates for environmental or occupational safety, accuracy is paramount.

PTFE filters capture solid particles without absorbing water vapor from the air. This stability ensures the filter's weight remains constant (low tare mass), leading to precise and interference-free measurements.

Degassing and Sterilizing Solvents

In analytical chemistry, such as HPLC, it is crucial to use pure, degassed solvents.

PTFE membrane filters are ideal for this task. They can sterilize organic-based mobile phases without altering their composition, as the filter will not absorb or react with the solvent.

Understanding the Trade-offs

No material is perfect for every task. The very property that makes PTFE filters so effective in some areas becomes a limitation in others.

The Challenge with Aqueous Solutions

The primary trade-off of hydrophobicity is that PTFE filters will not allow water or water-based solutions to pass through under normal pressure.

This makes them unsuitable for filtering standard aqueous samples. Forcing an aqueous solution through requires very high pressure or pre-wetting the membrane with an alcohol, which adds complexity to the process.

Not a Universal Solution

PTFE is the right tool for a specific set of jobs. For filtering aqueous solutions, a hydrophilic filter (such as nylon, PVDF, or PES) is the correct choice.

Understanding this distinction is the most important factor in selecting the right filter membrane for your application.

Making the Right Choice for Your Goal

Your application's needs will determine whether PTFE's hydrophobicity is an asset or a liability.

- If your primary focus is filtering gases, air, or vents: PTFE is the ideal choice because its hydrophobicity prevents moisture from blocking the filter pores.

- If your primary focus is filtering aggressive organic solvents or strong acids: PTFE's combined hydrophobicity and chemical inertness ensure sample purity and filter integrity.

- If your primary focus is filtering water-based (aqueous) solutions: You must choose a hydrophilic filter, as a standard PTFE membrane will actively resist the flow of water.

By understanding its inherent water-repelling nature, you can leverage PTFE's reliability for the most demanding technical applications.

Summary Table:

| Benefit | Key Application |

|---|---|

| Prevents pore blockage from moisture | Sterile tank venting, gas filtration |

| Ensures consistent gas/air flow | Aerosol sampling, air monitoring |

| Enables aggressive solvent filtration | HPLC solvent degassing, chemical processing |

| Acts as a sterile barrier | Bioprocessing, pharmaceutical manufacturing |

Need a reliable PTFE filter for your critical application?

KINTEK specializes in manufacturing high-performance, custom PTFE components, including filters, seals, and labware. Our precision production ensures your equipment performs reliably with gases, aggressive solvents, and in high-humidity environments.

Contact our experts today to discuss your specific requirements for the semiconductor, medical, laboratory, or industrial sectors. We provide custom fabrication from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F