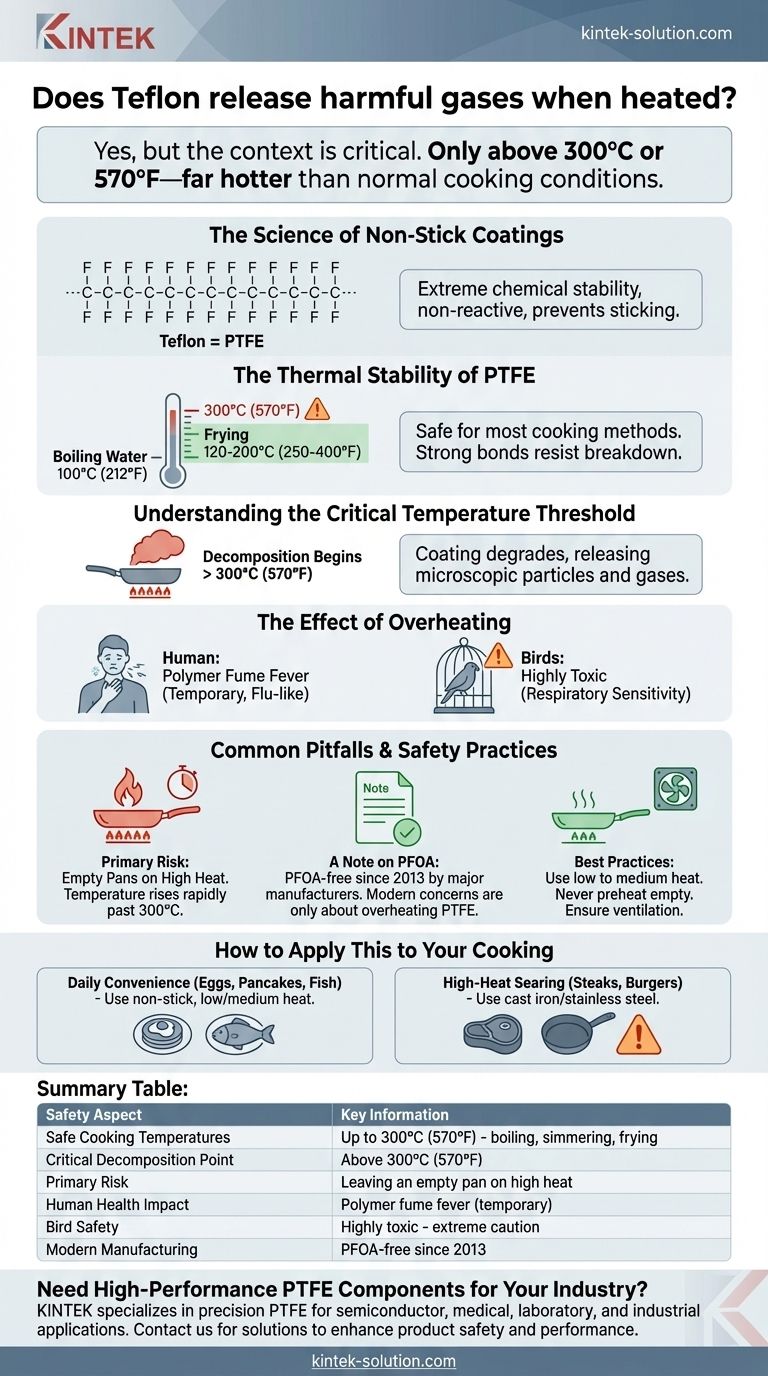

Yes, but the context is critical. Teflon cookware is exceptionally stable and safe under normal cooking conditions. It only begins to release potentially harmful fumes when heated to extremely high temperatures—above 300°C or 570°F—which is far hotter than the temperatures required for boiling, simmering, or frying.

The safety of Teflon cookware is not a question of if it can release fumes, but at what temperature it does. For all practical home cooking, the risk is negligible; the danger arises only from severe overheating, most commonly by leaving an empty pan on a high-heat burner.

The Science of Non-Stick Coatings

What is Teflon?

Teflon is a brand name for a synthetic polymer called Polytetrafluoroethylene (PTFE).

Its defining characteristic is extreme stability and non-reactivity. This chemical inertness is what makes its surface so slippery, preventing food from sticking.

The Thermal Stability of PTFE

The strong chemical bonds in PTFE make it resistant to breaking down. It maintains its integrity across a wide range of temperatures suitable for almost all cooking methods.

Water boils at 100°C (212°F), and most frying is done between 120-200°C (250-400°F). These temperatures are well within the safe operating range for PTFE coatings.

Understanding the Critical Temperature Threshold

When Decomposition Begins

The thermal breakdown of PTFE starts to occur at approximately 300°C (570°F).

Only when a pan exceeds this temperature does the coating begin to degrade, releasing microscopic particles and gases into the air.

The Effect of Overheating

If inhaled, these fumes can cause a temporary, flu-like condition in humans known as polymer fume fever.

It's important to note that these same fumes are highly toxic to birds, whose respiratory systems are far more sensitive.

Common Pitfalls and Safety Practices

The Primary Risk: Empty Pans

The most common way to dangerously overheat a non-stick pan is by leaving it empty on a high-heat burner.

Without food or liquid to absorb the energy, the pan's temperature can rise past the 300°C threshold in a matter of minutes.

A Note on PFOA

Many historical concerns about Teflon were related to PFOA, a chemical once used in its manufacturing process.

Major global manufacturers completely phased out the use of PFOA in their cookware starting in 2013. Modern concerns are focused solely on the issue of overheating the PTFE coating itself.

Best Practices for Safe Use

To eliminate any risk, always follow simple safety guidelines.

Never preheat an empty pan for an extended period. Use low to medium heat settings, which are sufficient for most non-stick cooking. And ensure your kitchen is properly ventilated.

How to Apply This to Your Cooking

To use your cookware safely and effectively, simply match the tool to the task.

- If your primary focus is daily convenience (eggs, pancakes, fish): Use your non-stick pans on low to medium heat and never leave them heating while empty.

- If your primary focus is high-heat searing (steaks, burgers): Use cookware made from cast iron or stainless steel, which are designed to handle these extreme temperatures without degrading.

- If you own pet birds: Be exceptionally cautious about any potential for overheating cookware, as their respiratory systems are uniquely sensitive.

By understanding the simple principles of heat management, you can confidently use non-stick cookware as the safe and effective tool it was designed to be.

Summary Table:

| Safety Aspect | Key Information |

|---|---|

| Safe Cooking Temperatures | Up to 300°C (570°F) - covers boiling, simmering, and frying |

| Critical Decomposition Point | Above 300°C (570°F) |

| Primary Risk | Leaving an empty pan on high heat |

| Human Health Impact | Polymer fume fever (temporary, flu-like symptoms) |

| Bird Safety | Highly toxic to birds - extreme caution required |

| Modern Manufacturing | PFOA-free since 2013 |

Need High-Performance PTFE Components for Your Industry?

At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that meet exact thermal and chemical stability requirements.

Contact us today to discuss how our PTFE solutions can enhance your product safety and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support