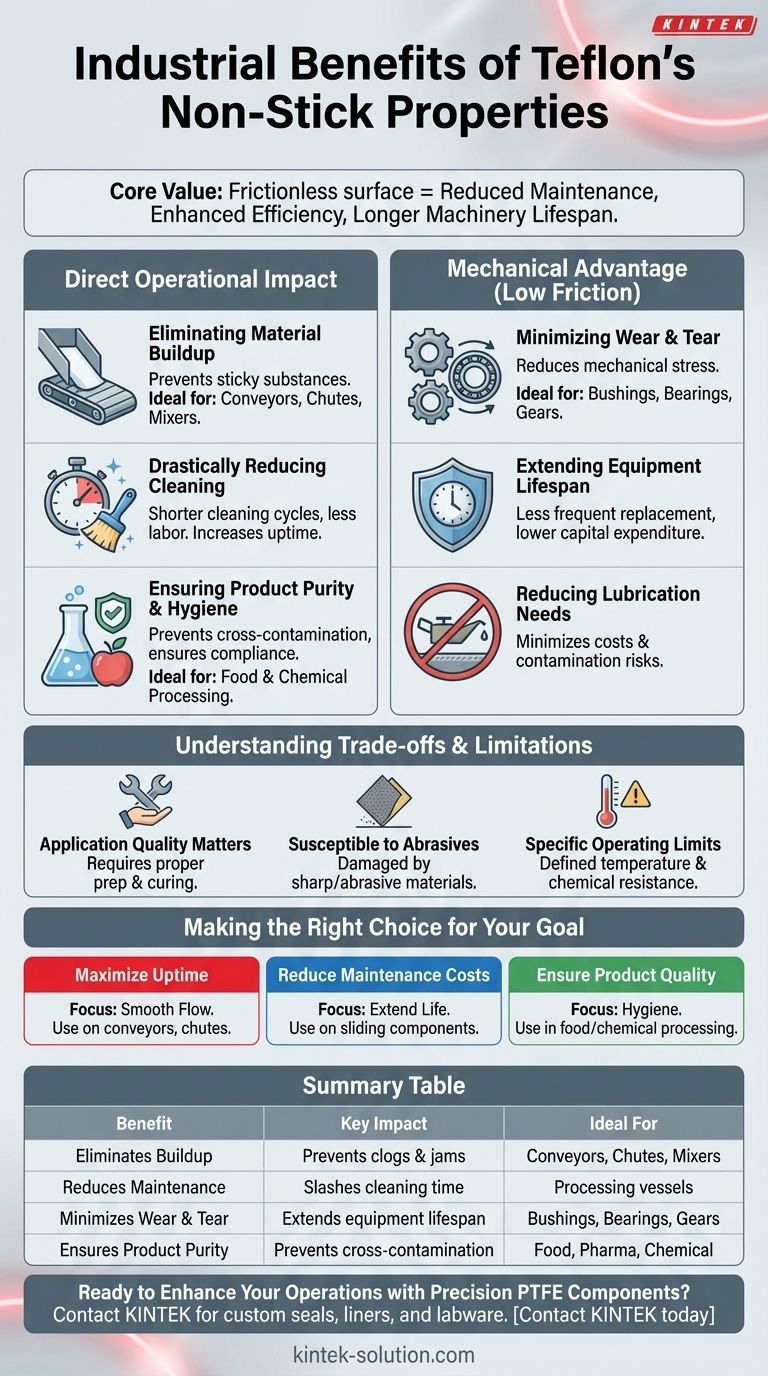

In an industrial context, the primary benefit of Teflon's non-stick property is its ability to create a nearly frictionless surface that repels a wide range of materials. This quality directly translates into reduced maintenance downtime, enhanced operational efficiency, and a longer lifespan for critical machinery by preventing the buildup of viscous substances, contaminants, and processing residue.

The core value of Teflon (PTFE) in industry is not merely that things don't stick to it; it's that this single property systematically reduces friction, contamination, and wear, leading to more resilient, efficient, and cost-effective operations.

The Direct Impact of Non-Stick Surfaces on Operations

The most immediate benefits of Teflon coatings are seen in the day-to-day flow of production and maintenance schedules. The inability of materials to adhere to a treated surface solves several fundamental operational challenges.

Eliminating Material Buildup

Teflon’s non-stick nature prevents sticky or viscous substances from adhering to equipment. This is critical for machinery like conveyor belts, chutes, and containers used in food processing, adhesive manufacturing, and packaging.

By repelling materials, the coating ensures a smooth, uninterrupted flow of products, preventing clogs and jams that would otherwise halt production.

Drastically Reducing Cleaning and Maintenance

When residue and contaminants do not adhere to surfaces, the need for intensive cleaning is significantly reduced. This leads to shorter cleaning cycles and less required labor.

This reduction in cleaning downtime means equipment is operational for more hours in a day, directly boosting productivity and output.

Ensuring Product Purity and Hygiene

In industries like food processing, preventing material buildup is essential for maintaining hygienic conditions. Teflon-coated surfaces are easier to clean and prevent cross-contamination between batches.

This ensures a higher quality, more consistent final product and simplifies compliance with regulatory standards.

The Mechanical Advantage of Low Friction

Beyond its non-stick quality, Teflon's exceptionally low coefficient of friction provides distinct mechanical and financial benefits, particularly for moving parts. It functions as a permanent dry lubricant.

Minimizing Wear and Tear

On components like bushings, bearings, and gears, the low-friction surface drastically reduces the mechanical stress caused by parts moving against each other.

This reduction in friction minimizes wear, which is the primary cause of mechanical failure and degradation over time.

Extending Equipment Lifespan

By mitigating the constant wear on machinery, Teflon coatings directly contribute to a longer operational lifespan for expensive equipment.

This reduces the frequency of component replacement and lowers long-term capital expenditure, delivering significant cost savings.

Reducing Lubrication Needs

The self-lubricating nature of a Teflon surface often minimizes or even eliminates the need for liquid lubricants. This cuts down on material costs and the labor required for regular lubrication.

It also removes a potential source of contamination, which is a critical benefit in cleanroom or food-grade environments.

Understanding the Trade-offs

While highly effective, Teflon coatings are not a universal solution. Understanding their limitations is key to successful implementation.

Application Is Key

The performance and durability of a Teflon coating depend heavily on the quality of its application. Proper surface preparation and curing are essential for achieving a strong bond and a flawless surface.

Susceptibility to Abrasives

Teflon coatings, while durable, can be damaged by sharp or highly abrasive materials. In environments with hard particulate matter, the non-stick surface can be scratched or worn away, diminishing its effectiveness.

Specific Operating Limits

Every formulation of Teflon has defined temperature and chemical resistance limits. Exposing a coating to conditions beyond its design specifications can cause it to degrade, compromising its performance and integrity.

Making the Right Choice for Your Goal

To leverage Teflon's properties effectively, align the application with your primary operational objective.

- If your primary focus is maximizing uptime: Use Teflon coatings on conveyors, chutes, and mixing vessels to prevent product buildup and slash cleaning times.

- If your primary focus is reducing long-term maintenance costs: Apply Teflon to bushings, gears, and sliding components to minimize wear and extend the life of your machinery.

- If your primary focus is product quality and purity: Implement Teflon coatings in food or chemical processing equipment to ensure hygienic conditions and prevent cross-contamination.

Ultimately, integrating Teflon's unique surface properties into your industrial environment is a strategic decision that creates more robust and efficient systems.

Summary Table:

| Benefit | Key Impact | Ideal For |

|---|---|---|

| Eliminates Material Buildup | Prevents clogs & jams; ensures smooth product flow | Conveyors, chutes, mixers |

| Reduces Maintenance | Slashes cleaning time & labor; increases uptime | Processing vessels, containers |

| Minimizes Wear & Tear | Acts as a dry lubricant; extends equipment lifespan | Bushings, bearings, gears |

| Ensures Product Purity | Prevents cross-contamination; simplifies hygiene | Food, pharmaceutical, chemical processing |

Ready to Enhance Your Operations with Precision PTFE Components?

KINTEK specializes in manufacturing high-performance PTFE (Teflon) components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a solution tailored to maximize your uptime, reduce maintenance costs, and protect product integrity.

Contact KINTEK today to discuss how our PTFE solutions can solve your specific industrial challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do the non-stick properties of PTFE benefit sealing technology? Enhance Seal Life and Purity

- Why are PTFE valves used in chemical flow applications? For Unmatched Chemical Inertness and Purity

- How do custom Teflon rotary shaft seals contribute to operational efficiency? Maximize Reliability & Cut Costs

- Why is the manufacturing cost of PTFE processing machines high? The Engineering Behind High-Performance Polymer Processing

- What considerations are important for PTFE CNC machining? Master Precision Machining for High-Performance Components

- What is PTFE and why is it used in fasteners for medical devices? Ensure Safety with Biocompatible Materials

- What are the best practices for precision PTFE machining? Master the Finesse for Flawless Components

- What are the advantages of PTFE bushings? Achieve Maintenance-Free, High-Performance Operation