The non-stick nature of PTFE is fundamental to its success in sealing technology. This unique property prevents process media from adhering to the seal surface, which could otherwise cause contamination, buildup, and eventual failure. This non-stick characteristic is a direct result of PTFE's extremely low coefficient of friction, which also drastically reduces wear and heat generation in dynamic applications, leading to a longer and more reliable service life.

While its non-stick quality is crucial for preventing system contamination and seal degradation, PTFE's true value emerges from the synergy of this low-friction surface with its exceptional chemical resistance and unique ability to physically conform to mating surfaces.

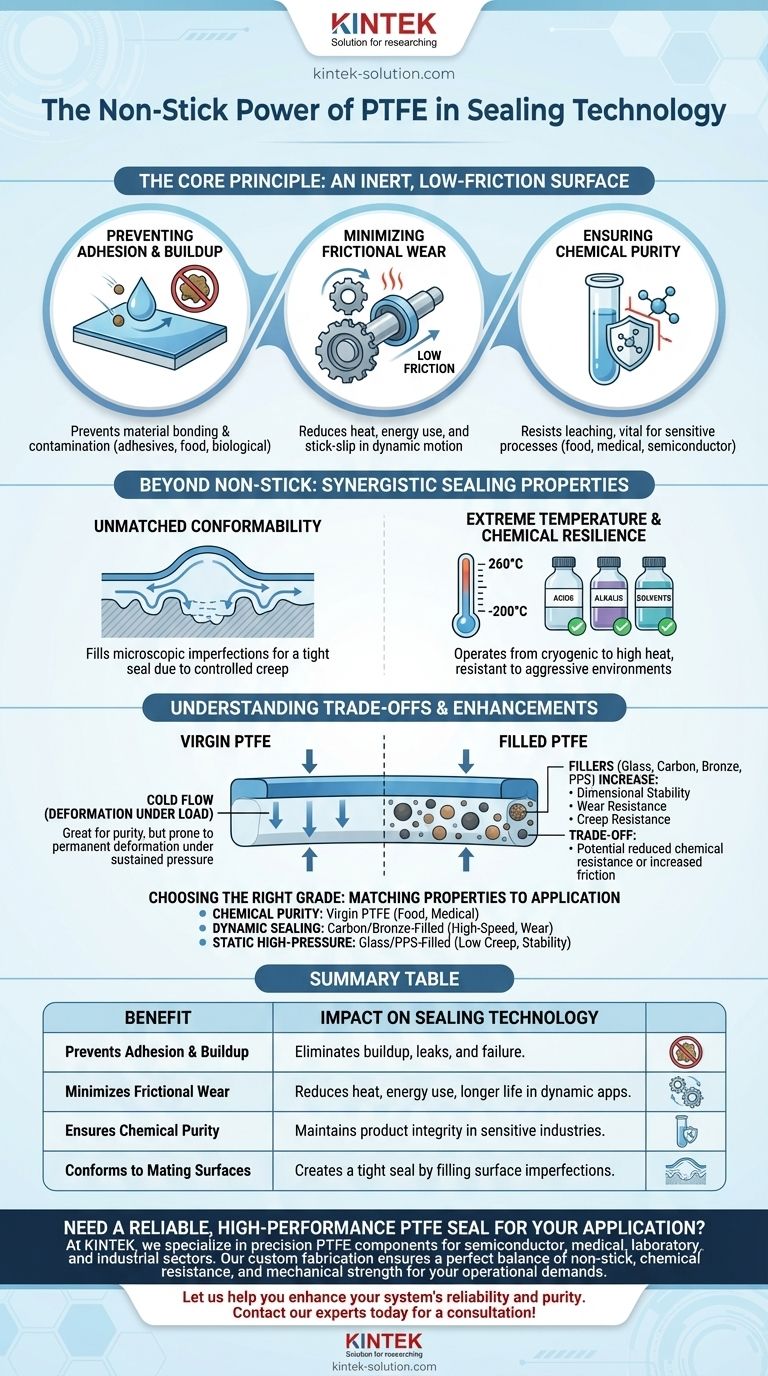

The Core Principle: An Inert and Low-Friction Surface

The benefits of PTFE’s non-stick properties in sealing are twofold: they protect the purity of the system and the physical integrity of the seal itself.

Preventing Adhesion and Buildup

In many industrial processes, the substances being sealed are sticky or prone to leaving deposits. PTFE’s non-stick surface ensures that materials like adhesives, food products, or biological matter slide past without bonding to the seal.

This prevents the gradual buildup of material that could compromise the seal's geometry and lead to leaks.

Minimizing Frictional Wear

A seal in a dynamic application, such as on a rotating shaft, is in constant motion. PTFE’s low coefficient of friction—one of the lowest of any solid material—is critical here.

It minimizes the "stick-slip" phenomenon, where the seal alternately grabs and releases the moving surface. This results in smoother operation, less heat generation, lower energy consumption, and significantly less wear on both the seal and the shaft.

Ensuring Chemical Purity

PTFE's non-stick surface is an extension of its chemical inertness. Because it resists bonding with other molecules, it does not react with or leach into the media it is sealing.

This property is non-negotiable in sensitive applications like food production, medical devices, and semiconductor manufacturing, where maintaining the purity of the end product is paramount.

Beyond Non-Stick: Properties That Create a Superior Seal

While the non-stick quality is a headline feature, it works in concert with other unique characteristics to make PTFE an elite sealing material.

Unmatched Conformability

Pure PTFE exhibits a property known as creep, or a lack of "material memory." While this can be a drawback in some contexts, it is a significant advantage in sealing.

This allows the PTFE to flow under pressure into the microscopic imperfections and irregularities of the mating surfaces, creating a highly effective and tight seal where more rigid materials would fail.

Extreme Temperature and Chemical Resilience

PTFE maintains its integrity across an exceptionally wide temperature range, from cryogenic lows of -200°C (-328°F) to highs of 260°C (500°F).

Furthermore, it is resistant to nearly all industrial acids, alkalis, and solvents. This makes it the default choice for aggressive chemical environments where conventional elastomers would quickly degrade.

Understanding the Trade-offs and Enhancements

Virgin PTFE is not a universal solution. Its primary weakness must be understood and managed for successful application.

The Challenge of 'Cold Flow'

The same material creep that allows PTFE to conform so well can also be a liability. Under sustained high pressure and temperature, pure PTFE can permanently deform or "flow" away from the load point.

This phenomenon, known as cold flow, can lead to a loss of sealing force over time, particularly in static, high-load applications.

The Role of Fillers

To counteract cold flow and enhance other properties, PTFE is often blended with fillers. Each filler offers a different set of improvements.

Fillers like glass fiber, carbon, bronze, or PPS are added to increase dimensional stability, improve wear resistance, and significantly reduce the tendency to creep under load. Additives like graphite can further reduce friction.

Balancing Properties for the Application

Introducing a filler is a trade-off. While it enhances mechanical strength and stability, it can sometimes slightly diminish the material's chemical resistance or increase the coefficient of friction compared to virgin PTFE.

Therefore, the choice of a filled or unfilled PTFE depends entirely on the specific demands of the sealing environment.

Making the Right Choice for Your Application

Selecting the correct grade of PTFE requires matching its properties to the operational demands of your system.

- If your primary focus is chemical purity and preventing contamination: Choose virgin PTFE for its unmatched inertness and non-stick surface, ideal for food, medical, or semiconductor processes.

- If your primary focus is high-speed dynamic sealing: Select a carbon or bronze-filled PTFE to manage frictional heat, provide superior wear resistance, and ensure a long operational life.

- If your primary focus is static sealing under high pressure: Use a glass-filled or PPS-filled PTFE to significantly reduce material creep and maintain a consistent sealing force over time.

By understanding how PTFE’s core properties solve specific engineering challenges, you can select the precise material to ensure a durable and reliable seal.

Summary Table:

| Benefit | Impact on Sealing Technology |

|---|---|

| Prevents Adhesion & Buildup | Eliminates material buildup that can cause leaks and seal failure. |

| Minimizes Frictional Wear | Reduces heat, energy use, and wear for longer service life in dynamic applications. |

| Ensures Chemical Purity | Maintains product integrity in sensitive industries like medical and semiconductor. |

| Conforms to Mating Surfaces | Creates a tight seal by filling microscopic imperfections on flange or shaft surfaces. |

Need a reliable, high-performance PTFE seal for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a seal that perfectly balances non-stick properties, chemical resistance, and mechanical strength for your specific operational demands.

Let us help you enhance your system's reliability and purity. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance