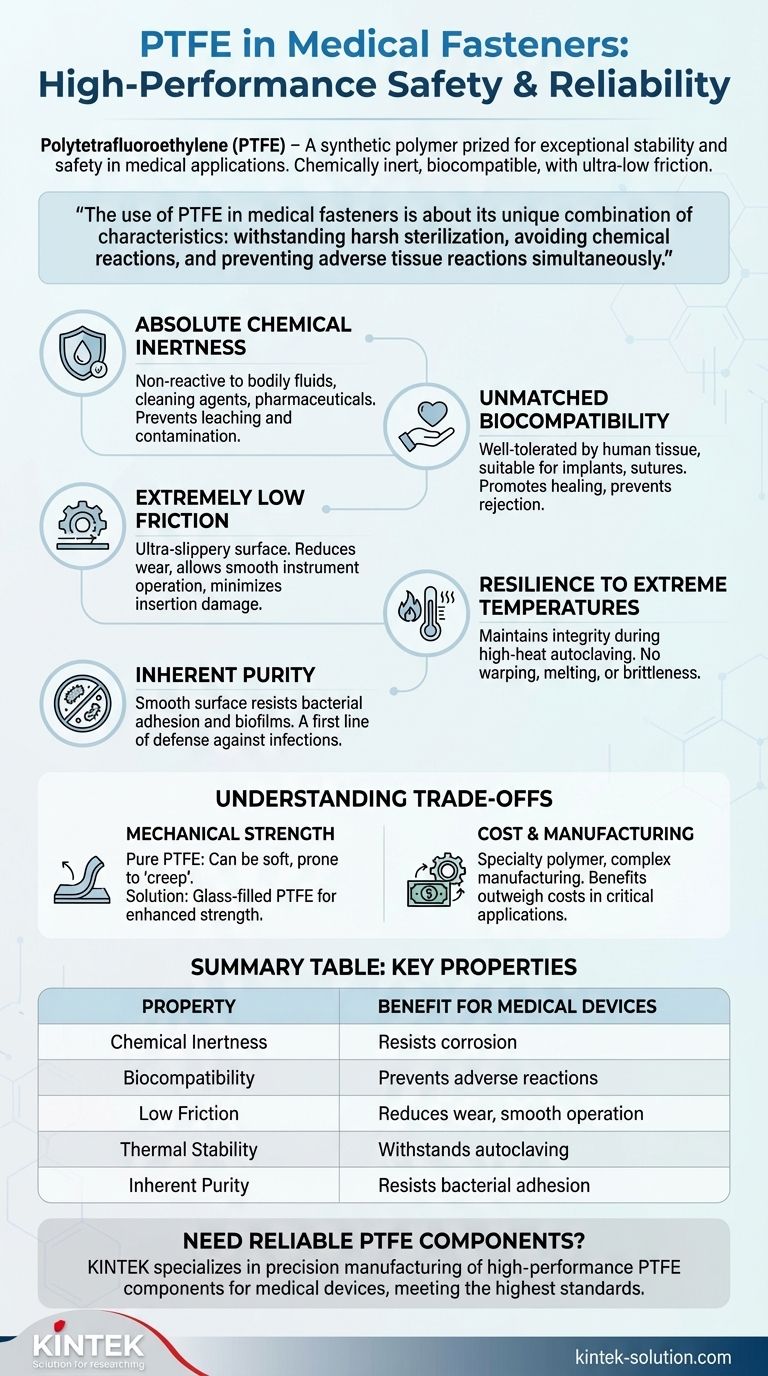

At its core, Polytetrafluoroethylene (PTFE) is a high-performance synthetic polymer prized in medical applications for its exceptional stability and safety. Fasteners made from or coated with PTFE are used in medical devices because they are chemically inert, biocompatible with human tissue, and possess an extremely low coefficient of friction, ensuring device reliability and patient safety.

The use of PTFE in medical fasteners is not about finding a single best property, but about its unique combination of characteristics. It is one of the few materials that can withstand harsh sterilization, avoid chemical reactions with bodily fluids, and prevent adverse tissue reactions simultaneously.

Why Material Choice is So Critical in Medicine

In medical device engineering, the choice of material is fundamental to patient safety and device efficacy. The internal environment of the human body is aggressive, and any component must perform flawlessly without causing harm.

The Problem of Bioreactivity

Most materials, when introduced into the body, trigger an immune response or degrade when exposed to bodily fluids. This can lead to inflammation, rejection, or device failure.

A material must be biocompatible, meaning it does not provoke an adverse reaction from living tissue. This is a non-negotiable requirement for implants and any device with direct tissue contact.

The Challenge of Contamination and Sterilization

Medical instruments must be completely sterile to prevent infection. This often involves harsh processes like high-temperature autoclaving or exposure to potent chemical agents.

The chosen material must withstand these sterilization cycles repeatedly without degrading. Furthermore, its surface must resist the adhesion and growth of bacteria to minimize contamination risk.

The Defining Properties of PTFE for Medical Fasteners

PTFE solves these medical challenges through a distinct set of inherent properties, making it an ideal choice for fasteners in everything from surgical tools to long-term implants.

Absolute Chemical Inertness

PTFE is one of the most non-reactive substances known. Fasteners made from it will not corrode or break down when exposed to bodily fluids, aggressive cleaning agents, or pharmaceuticals.

This inertness guarantees that the fastener will not leach harmful substances into the patient or contaminate sensitive diagnostic tests, preserving the integrity of the device and the procedure.

Unmatched Biocompatibility

Due to its chemical stability, PTFE is exceptionally well-tolerated by the human body. It is considered a highly biocompatible polymer, making it suitable for sutures, implants, and catheters.

This property ensures that PTFE fasteners will not cause irritation or an immune response, promoting better healing and long-term device acceptance.

Extremely Low Friction

PTFE has an incredibly low coefficient of friction, making its surface extremely slippery. This is why it is famous as a non-stick coating.

In medical devices, this low-friction surface reduces wear and tear on moving parts, allows instruments to operate smoothly, and helps catheters be inserted with minimal tissue damage.

Resilience to Extreme Temperatures

PTFE fasteners maintain their structural integrity across a wide range of temperatures. This is critical for any component that must endure the high heat and pressure of steam sterilization (autoclaving).

This thermal stability ensures that a fastener will not warp, melt, or become brittle, guaranteeing its reliability over many cycles of use.

Inherent Purity

The molecular structure and smooth surface of PTFE make it difficult for bacteria to adhere and form biofilms. This inherent purity is a first line of defense against device-related infections.

This quality is especially vital in applications like fluid handling systems and surgical instruments where preventing microbial contamination is paramount.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every application. Acknowledging its limitations is key to proper engineering design.

Mechanical Strength

Pure PTFE is a relatively soft material and can be prone to "creep," or deforming under a sustained load. It has lower tensile strength compared to metals or other engineering plastics.

To counteract this, PTFE is often enhanced with fillers like glass or carbon. Glass-filled PTFE offers significantly improved stiffness and wear resistance, making it suitable for more demanding structural roles in surgical tools or implants.

Cost and Manufacturing

PTFE is a specialty polymer that is more expensive and complex to manufacture into precise shapes than common materials like stainless steel or standard plastics.

The costs associated with raw material and specialized machining must be weighed against the critical performance benefits it provides, especially in high-stakes applications.

Making the Right Choice for Your Application

Selecting the correct fastener material depends entirely on the specific demands of the medical device and its intended use.

- If your primary focus is direct, long-term tissue contact (e.g., implants, sutures): The unmatched biocompatibility and chemical inertness of pure PTFE are non-negotiable.

- If your primary focus is reusable surgical instruments: The ability of PTFE to withstand repeated sterilization cycles and resist corrosion from cleaning agents is the most critical factor.

- If your primary focus is a structural component with high mechanical load: Consider a glass-filled PTFE to gain the necessary strength and rigidity while retaining its core chemical benefits.

Ultimately, leveraging PTFE in medical fasteners is a deliberate engineering choice to ensure a device is not just effective, but fundamentally safe.

Summary Table:

| Property | Benefit for Medical Devices |

|---|---|

| Chemical Inertness | Resists corrosion from bodily fluids and cleaning agents. |

| Biocompatibility | Prevents adverse tissue reactions, ideal for implants. |

| Low Friction | Reduces wear, allows for smooth operation and insertion. |

| Thermal Stability | Withstands repeated autoclaving and sterilization cycles. |

| Inherent Purity | Resists bacterial adhesion, minimizing infection risk. |

Need reliable PTFE components for your medical device?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including seals, liners, and custom fasteners. Our expertise ensures your medical, laboratory, or industrial products meet the highest standards of safety, reliability, and biocompatibility.

We offer custom fabrication from prototypes to high-volume orders, tailoring solutions for the semiconductor, medical, and other specialized industries.

Contact our experts today to discuss how our PTFE solutions can enhance your device's performance and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications