The high cost of PTFE processing machinery is a direct result of the material's uniquely challenging physical properties. Unlike common plastics, PTFE cannot be simply melted and molded. This requires fundamentally different, more complex, and robust machinery built from specialized, expensive materials to handle the extreme conditions necessary for processing.

The core reason for the high cost is a necessary chain reaction: PTFE's extreme melt viscosity forbids standard processing, forcing the use of complex, multi-stage techniques like compression and sintering. These techniques, in turn, demand machines built from expensive, highly durable, and corrosion-resistant alloys capable of withstanding immense pressure and temperature.

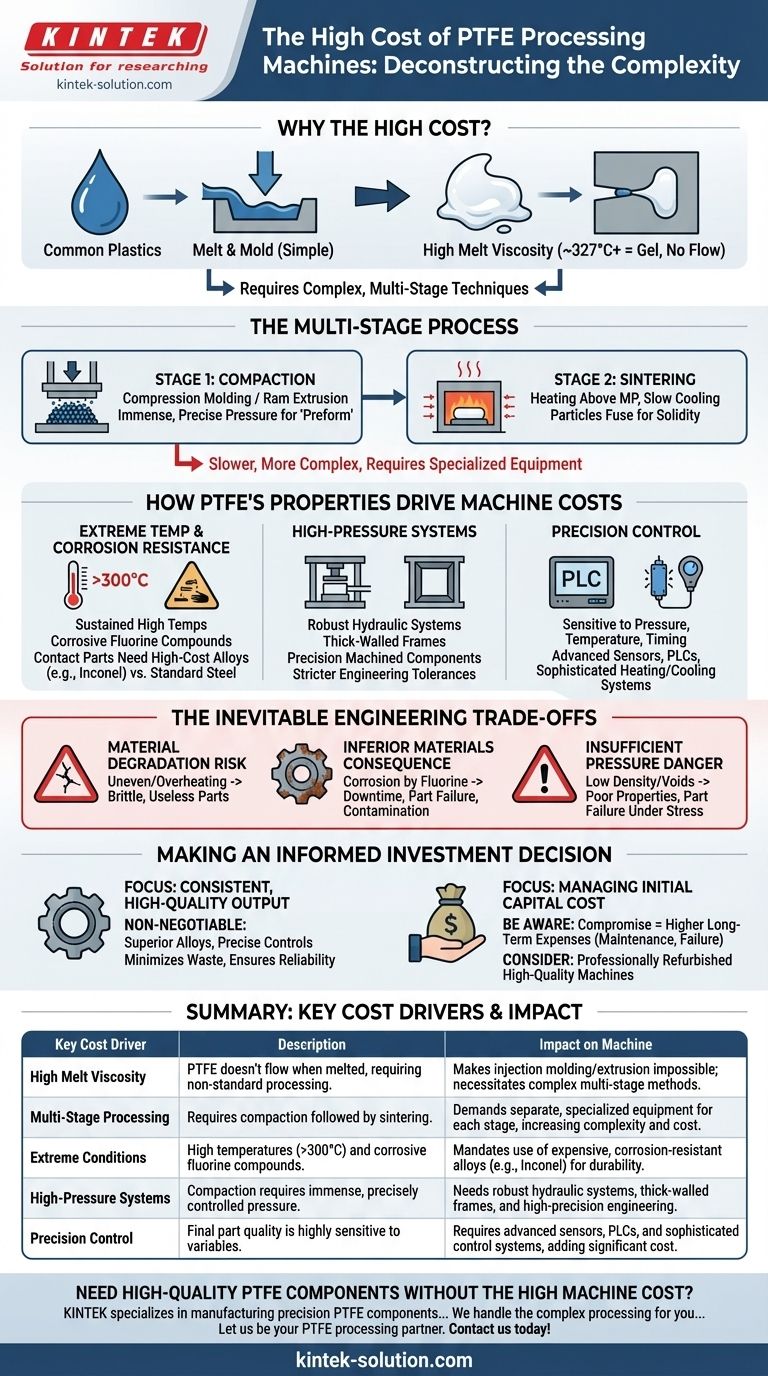

Deconstructing the "Complexity" of PTFE Processing

To understand the cost of the machinery, we must first understand the difficult nature of Polytetrafluoroethylene (PTFE) itself. It does not behave like a typical thermoplastic.

The High-Viscosity Challenge

PTFE has an exceptionally high melt viscosity, meaning even when heated past its melting point of ~327°C, it doesn't flow like a liquid. It becomes a translucent, weak gel.

This single property makes conventional, high-volume methods like injection molding or standard extrusion impossible. The material simply won't flow into a mold or through a standard die.

The Multi-Stage Process: Compaction and Sintering

Because it can't be melt-processed, PTFE requires a multi-stage approach similar to powder metallurgy.

First, the granular PTFE powder is compacted into a desired shape, called a "preform," using methods like compression molding or ram extrusion. This requires immense, carefully controlled pressure.

Second, this fragile preform must be heated in a special oven in a process called sintering. The part is heated above its melting point and then slowly cooled, allowing the individual PTFE particles to fuse together into a solid, durable object.

This two-step process is inherently slower, more complex, and requires more specialized equipment than the single-step processing of other polymers.

How PTFE's Properties Drive Machine Costs

The unconventional processing requirements dictate that the machinery must be engineered to a much higher standard than typical plastics equipment.

Extreme Temperature and Corrosion Resistance

Processing PTFE requires sustained, precise temperatures well above 300°C. At these temperatures, any impurities or degradation can release highly corrosive fluorine compounds.

Therefore, all machine components that contact the PTFE—such as barrels, molds, and dies—must be constructed from specialized, high-cost alloys like nickel-based superalloys (e.g., Inconel) that can resist both the heat and the chemical attack. Standard hardened steel would quickly fail.

High-Pressure System Requirements

The compaction stage requires machines capable of generating and containing enormous pressures to form the initial shape.

This necessitates robust hydraulic systems, thick-walled steel frames, and precision-machined components to ensure safety, reliability, and the consistent density of the preform. The engineering tolerances for these systems are far stricter than for standard machinery.

The Need for Precision Control

The quality of the final PTFE part is highly sensitive to the exact pressure, temperature, and timing used during both compaction and sintering.

The machinery must incorporate sophisticated control systems to manage these variables precisely. This adds significant cost through advanced sensors, programmable logic controllers (PLCs), and finely tuned heating and cooling systems.

The Inevitable Engineering Trade-offs

Attempting to reduce manufacturing costs by compromising on these core requirements is a common but costly mistake. The unique nature of PTFE processing leaves little room for shortcuts.

The Risk of Material Degradation

Using inferior heating elements or control systems can lead to uneven heating or overheating. This permanently degrades the PTFE, destroying its exceptional properties and resulting in brittle, useless parts.

The Consequence of Inferior Materials

Building contact parts from cheaper metals is a false economy. They will inevitably corrode from the hot, reactive fluorine compounds, leading to frequent and expensive machine downtime, part replacement, and contamination of the final product.

The Dangers of Insufficient Pressure

A machine unable to generate and sustain the required compaction pressure will produce parts with low density and voids. These parts will have poor mechanical properties and will fail under stress, rendering them unsuitable for high-performance applications.

Making an Informed Investment Decision

Understanding these cost drivers allows you to align your investment with your primary operational goal.

- If your primary focus is consistent, high-quality output: Investing in a machine built with superior corrosion-resistant alloys and equipped with precise thermal and pressure control is non-negotiable. This is the only way to minimize material waste and ensure final part reliability.

- If your primary focus is managing initial capital cost: Be aware that compromising on the core engineering of a new machine often leads to higher long-term expenses through maintenance, downtime, and product failure. A better alternative may be sourcing professionally refurbished, high-quality specialized machinery.

Ultimately, the investment in a PTFE processing machine is an investment in mastering one of the world's most demanding and valuable engineering polymers.

Summary Table:

| Key Cost Driver | Description | Impact on Machine |

|---|---|---|

| High Melt Viscosity | PTFE doesn't flow when melted, requiring non-standard processing. | Makes injection molding/extrusion impossible; necessitates complex multi-stage methods. |

| Multi-Stage Processing | Requires compaction (compression molding/ram extrusion) followed by sintering. | Demands separate, specialized equipment for each stage, increasing complexity and cost. |

| Extreme Conditions | Processing involves high temperatures (>300°C) and corrosive fluorine compounds. | Mandates use of expensive, corrosion-resistant alloys (e.g., Inconel) for durability. |

| High-Pressure Systems | Compaction requires immense, precisely controlled pressure. | Needs robust hydraulic systems, thick-walled frames, and high-precision engineering. |

| Precision Control | Final part quality is highly sensitive to pressure, temperature, and timing. | Requires advanced sensors, PLCs, and sophisticated control systems, adding significant cost. |

Need High-Quality PTFE Components Without the High Machine Cost?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We handle the complex processing for you, delivering custom-fabricated parts from prototypes to high-volume orders with the reliability and performance your applications demand.

Let us be your PTFE processing partner. Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers