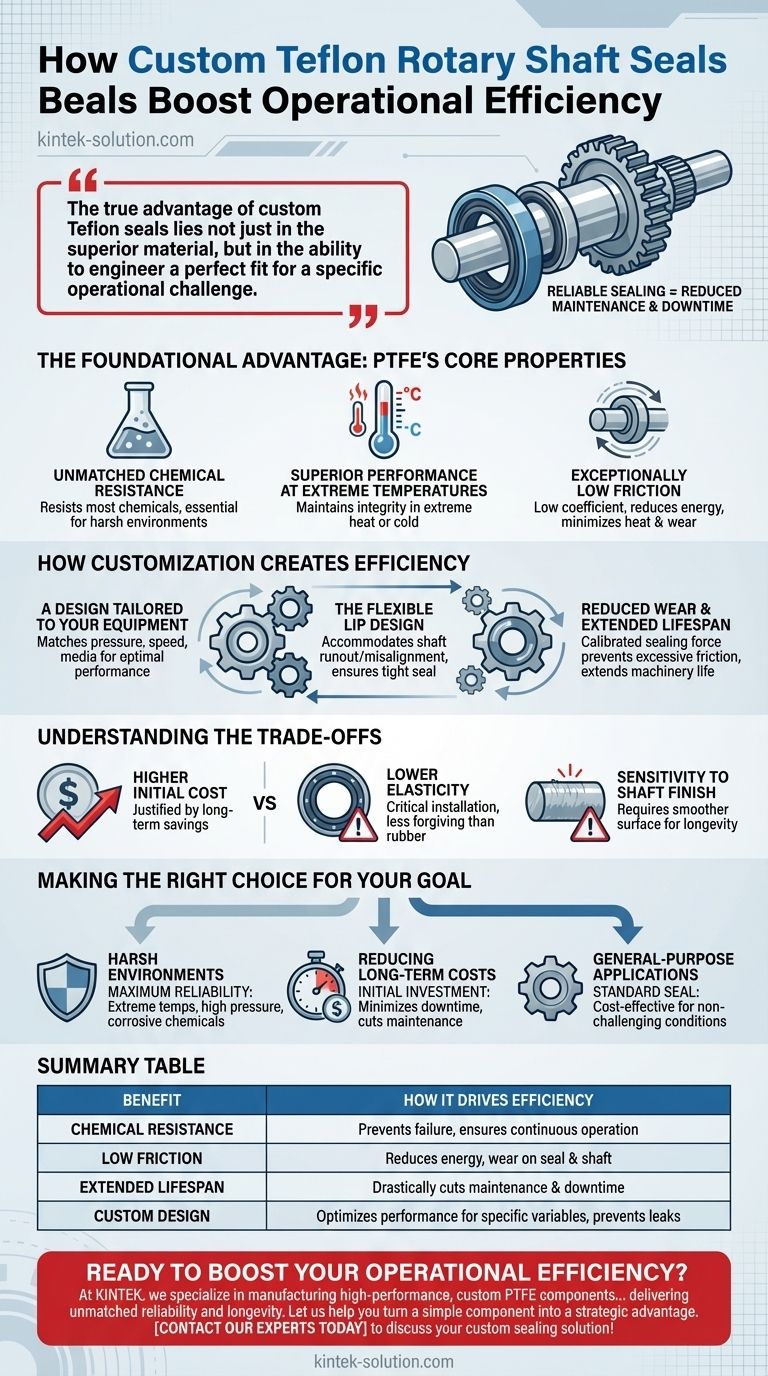

At their core, custom Teflon rotary shaft seals contribute to operational efficiency by providing a highly reliable, long-lasting sealing solution that drastically reduces maintenance requirements and equipment downtime. Their effectiveness stems from the unique properties of Polytetrafluoroethylene (PTFE) combined with design elements tailored specifically to the demands of a given application.

The true advantage of custom Teflon seals lies not just in the superior material, but in the ability to engineer a perfect fit for a specific operational challenge. This precision minimizes friction, prevents leaks under harsh conditions, and turns a simple component into a significant driver of long-term cost savings.

The Foundational Advantage: PTFE's Core Properties

To understand the impact of these seals, we must first understand the material itself. Custom rotary seals are fabricated from Polytetrafluoroethylene (PTFE), a fluoropolymer more commonly known by the brand name Teflon.

Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals and corrosive media. This makes it an essential choice in industries like chemical processing, where standard elastomer seals would quickly degrade and fail.

Superior Performance at Extreme Temperatures

These seals maintain their integrity and performance across an exceptionally wide temperature range. This resilience is critical for high-performance applications in the aerospace and automotive sectors, where machinery operates in extreme heat or cold.

Exceptionally Low Friction

One of PTFE's most significant properties is its extremely low coefficient of friction. This "slipperiness" reduces the energy needed to turn the shaft, minimizes heat generation, and dramatically cuts down on wear to both the seal and the shaft itself.

How Customization Creates Efficiency

While the material is foundational, the "custom" aspect is what unlocks its full potential. A generic seal cannot account for the unique variables of your equipment.

A Design Tailored to Your Equipment

Customization allows the seal's profile, materials, and spring-energizer to be matched perfectly to the application's pressure, speed, and media. This ensures optimal performance where an off-the-shelf part would be a compromise.

The Flexible Lip Design

A key feature is the flexible lip, which can be engineered to maintain constant, effective contact with the shaft. This design accommodates minor shaft runout or misalignment, ensuring a tight seal and preventing leaks even under challenging, real-world conditions.

Reduced Wear and Extended Lifespan

By optimizing the design, the sealing force is calibrated to be just enough to prevent leakage without creating excessive friction. This balance is key to extending the lifespan of the machinery and minimizing the need for premature replacement, directly reducing maintenance needs.

Understanding the Trade-offs

No engineering choice is without its compromises. A clear understanding of the limitations is essential for making an informed decision.

Higher Initial Cost

Custom-engineered PTFE seals typically have a higher upfront cost than standard, mass-produced elastomeric (rubber) seals. The investment is justified by the reduction in long-term operational and maintenance expenses.

Lower Elasticity

Compared to rubber, PTFE has less "memory" and is more rigid. This makes proper installation technique absolutely critical. An improperly installed PTFE seal is more likely to fail than a more forgiving elastomeric counterpart.

Sensitivity to Shaft Finish

For optimal performance and longevity, PTFE seals often require a smoother shaft surface finish than traditional seals. A rough shaft can accelerate wear on the seal lip, negating its long-life benefits.

Making the Right Choice for Your Goal

Ultimately, the decision to use custom Teflon seals depends on your primary operational objective.

- If your primary focus is maximum reliability in harsh environments: Custom Teflon seals are the superior choice for applications involving extreme temperatures, high pressures, or corrosive chemicals.

- If your primary focus is reducing long-term operational costs: The initial investment in these seals provides significant returns by minimizing downtime, cutting maintenance labor, and extending the life of critical equipment.

- If your primary focus is general-purpose, low-demand applications: A standard elastomeric seal may be a more cost-effective solution when operating conditions are not challenging.

Choosing the right seal is a strategic investment in the reliability and efficiency of your entire operation.

Summary Table:

| Benefit | How It Drives Efficiency |

|---|---|

| Chemical Resistance | Prevents failure in harsh environments, ensuring continuous operation. |

| Low Friction | Reduces energy consumption and wear on both the seal and shaft. |

| Extended Lifespan | Drastically cuts maintenance frequency and associated downtime. |

| Custom Design | Optimizes performance for specific pressure, speed, and media, preventing leaks. |

Ready to boost your operational efficiency and reduce long-term costs?

At KINTEK, we specialize in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering ensures a perfect fit for your specific application, delivering unmatched reliability and longevity.

Let us help you turn a simple component into a strategic advantage. Contact our experts today to discuss your custom sealing solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials