In chemical flow applications, PTFE valves are specified for one primary reason: their unparalleled chemical inertness. This synthetic fluoropolymer, also known as Polytetrafluoroethylene, does not react with even the most aggressive chemicals, which prevents two critical failures. It stops the valve itself from corroding and ensures the chemical product passing through it remains completely unaltered and pure.

The selection of PTFE for chemical valves is not just about resisting corrosion; it's about guaranteeing process integrity. Its unique combination of chemical inertness, thermal stability, and low-friction surfaces ensures the fluid remains pure and the valve operates reliably over a long lifespan.

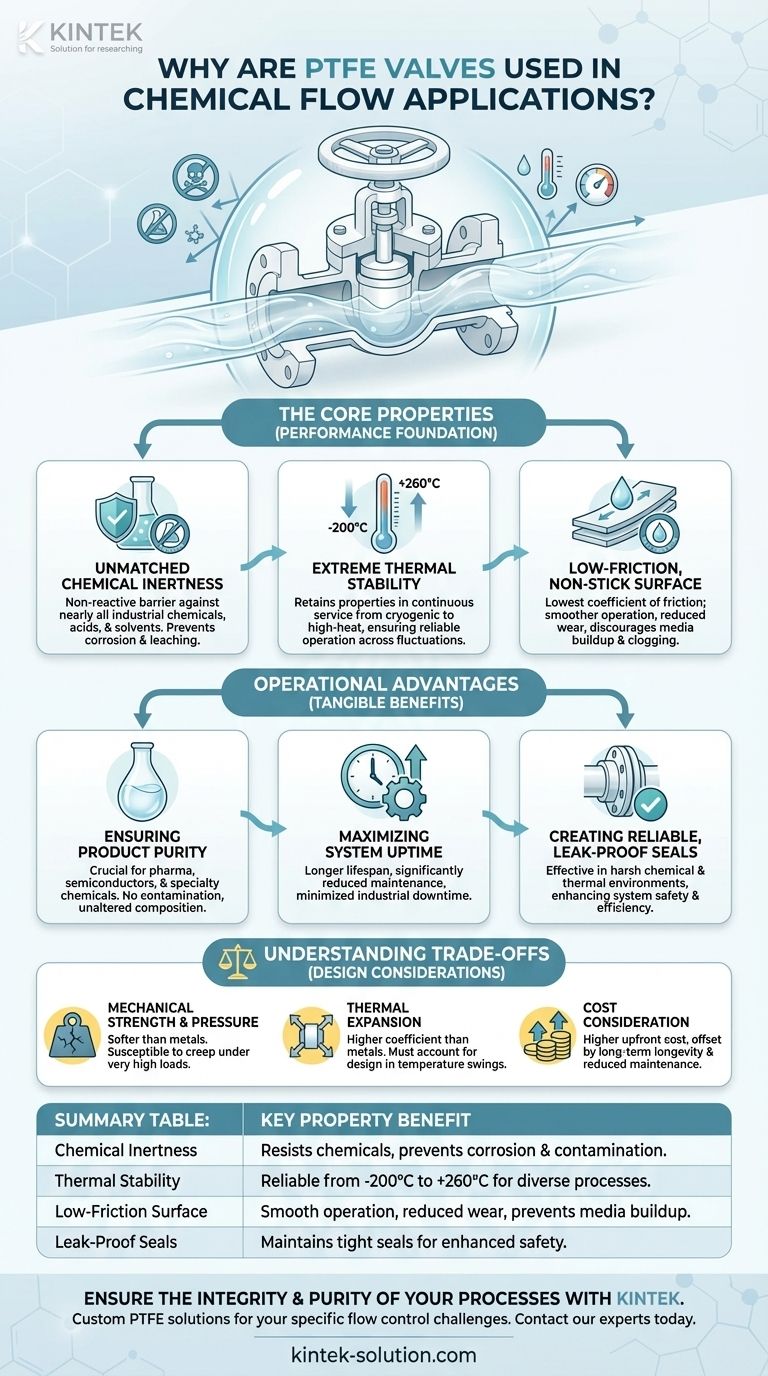

The Core Properties That Define PTFE Performance

To understand why PTFE is the default choice for demanding chemical environments, we must look at its fundamental material properties. These characteristics work together to deliver performance that traditional metals and other plastics cannot match.

Unmatched Chemical Inertness

PTFE is chemically inert, meaning it is highly resistant to reaction with nearly all industrial chemicals, acids, and solvents. This is its most critical feature for chemical handling.

Unlike metal alloys that can corrode or leach ions, PTFE provides a non-reactive barrier. This ensures the chemical's composition, color, or purity is not compromised during transit.

Extreme Thermal Stability

Industrial chemical processes often involve a wide range of temperatures. PTFE is exceptionally stable across these fluctuations.

It retains its core properties in continuous service from -200ºC up to +260ºC (-328ºF to +500ºF), making it one of the most thermally-stable plastics available. This allows a single valve material to be used in both cryogenic and high-temperature applications.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating an inherently non-stick and self-lubricating surface.

For a valve, this means smoother operation of moving parts, less torque required for actuation, and reduced wear over time. This property also discourages media buildup, which contributes to a self-cleaning effect and prevents clogging.

The Operational Advantages in Chemical Systems

These material properties translate directly into tangible operational benefits that are critical for industries where safety, purity, and uptime are paramount.

Ensuring Product Purity

In sectors like pharmaceuticals, semiconductors, or specialty chemicals, even trace contamination can ruin an entire batch. PTFE's inert nature is non-negotiable in these contexts.

For example, in a paint dispersion machine, a metal valve could slightly react with pigments, altering the final color. A PTFE valve eliminates this risk entirely.

Maximizing System Uptime

The durability and chemical resistance of PTFE components lead to a longer operational lifespan and significantly reduced maintenance requirements.

Fewer replacements and less need for service translate directly to minimized industrial downtime. This results in greater productivity and lower long-term operational costs.

Creating Reliable, Leak-Proof Seals

PTFE's physical properties make it an excellent material for gaskets and seals within the valve assembly.

It creates tight, leak-proof seals that remain effective even in harsh chemical and thermal environments, enhancing the safety and efficiency of the entire system.

Understanding the Trade-offs

While PTFE offers exceptional performance, it's essential to understand its limitations to make an informed engineering decision. No material is perfect for every scenario.

Mechanical Strength and Pressure

PTFE is a relatively soft material compared to metals. It can be susceptible to creep and deformation under very high mechanical loads or pressures, especially at elevated temperatures. In such cases, a PTFE-lined metal valve may be a better solution.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. This must be accounted for in the design of systems that experience significant temperature swings to avoid stress or sealing issues.

Cost Consideration

High-performance polymers like PTFE typically have a higher upfront material cost than common metals like stainless steel. However, this initial investment is often offset by the material's extended lifespan and reduced maintenance needs.

Making the Right Choice for Your Application

Selecting the correct valve material depends entirely on the specific demands of your process.

- If your primary focus is handling highly corrosive or high-purity fluids: PTFE is the default choice due to its chemical inertness, which protects both the valve and the medium.

- If your primary focus is high-pressure or high-mechanical-stress applications: You may need to consider metal valves or PTFE-lined metal valves to combine chemical resistance with structural strength.

- If your primary focus is minimizing long-term operational costs: The higher initial cost of PTFE is often justified by its longevity, reduced maintenance needs, and prevention of costly downtime.

Ultimately, choosing PTFE is an investment in the long-term reliability and integrity of your chemical flow system.

Summary Table:

| Key Property | Benefit for Chemical Flow Applications |

|---|---|

| Chemical Inertness | Resists virtually all chemicals, preventing corrosion and contamination. |

| Thermal Stability | Performs reliably from -200°C to +260°C, suitable for diverse processes. |

| Low-Friction Surface | Ensures smooth operation, reduces wear, and prevents media buildup. |

| Leak-Proof Seals | Maintains tight seals in harsh environments for enhanced safety. |

Ensure the integrity and purity of your chemical processes with precision-engineered PTFE components from KINTEK.

Whether you are in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom PTFE fabrication—from prototypes to high-volume orders—guarantees a solution tailored to your specific flow control challenges. Our components are designed to maximize uptime, protect your product, and reduce long-term costs.

Contact our experts today to discuss how we can support your application with high-performance PTFE valves, seals, liners, and labware.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection