The short answer is that there is no single standard tolerance for PTFE balls; it depends entirely on the grade and intended application. Tolerances can range from a broad ±5% for general-purpose use to as tight as ±0.003 inches for precision engineering applications.

The key takeaway is that PTFE ball tolerances are not universal. They are a specification you must define based on your application's needs, with a direct trade-off between precision and cost.

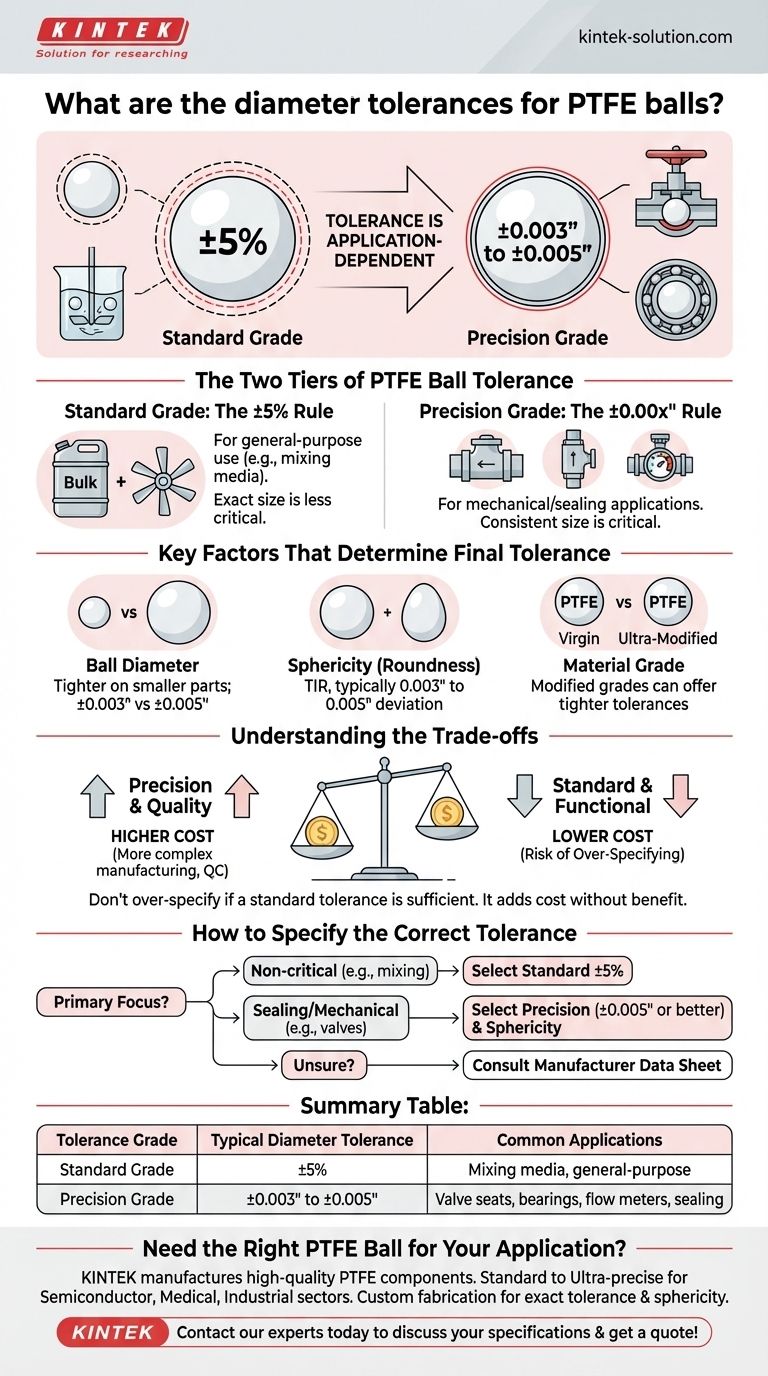

The Two Tiers of PTFE Ball Tolerance

PTFE's unique properties make it suitable for a wide range of uses, from simple mixing media to high-performance valve seats. This has led to two distinct tiers of manufacturing tolerance.

Standard Grade: The ±5% Rule

For many bulk applications, a loose tolerance is perfectly acceptable. A ±5% diameter tolerance is a common specification for these general-purpose balls.

This grade is often used where the ball's exact size is less critical than its chemical inertness or low-friction properties, such as in mixing or media agitation.

Precision Grade: The ±0.00x" Rule

For mechanical or sealing applications, a much tighter tolerance is required. Here, tolerances are specified in thousandths of an inch.

These precision balls are manufactured for specific engineering functions where consistent size is critical for performance, such as in check valves, bearings, or flow meters.

Key Factors That Determine Final Tolerance

When you move into precision grades, several interconnected factors determine the achievable tolerance. You must consider these when specifying a part.

Ball Diameter

The size of the ball itself is a primary factor. As a general manufacturing principle, a tighter absolute tolerance is often easier to hold on smaller parts.

- Larger Balls: Typically have a tolerance around

±0.005 inches. - Smaller Balls: Can often be held to a tighter tolerance, such as

±0.003 inches.

Sphericity (Roundness)

Diameter tolerance alone does not guarantee a part is perfectly round. Sphericity, often measured as Total Indicator Reading (TIR), specifies how much the ball's surface deviates from a perfect sphere.

A ball can be within its diameter tolerance at every point of measurement but still be slightly egg-shaped. Therefore, precision applications require specifying both a diameter tolerance and a maximum TIR, which can also range from 0.003" to 0.005".

Material Grade

The type of PTFE resin used also plays a role. PTFE balls are available in different grades, such as Virgin or Ultra-Modified.

Modified grades can offer enhanced dimensional stability and resistance to creep, which may allow for more consistent and tighter manufacturing tolerances compared to standard virgin PTFE.

Understanding the Trade-offs

Choosing the right tolerance is a critical design decision with direct consequences for your project's budget and performance.

The Cost of Precision

Tighter tolerances are never free. Achieving a ±0.003" tolerance with a 0.003" TIR requires more sophisticated manufacturing processes, stricter quality control, and higher rejection rates.

This means a precision-grade PTFE ball can cost significantly more than a standard-grade ball of the same size.

The Risk of Over-Specifying

A common engineering mistake is to specify a tighter tolerance than the application truly requires. This adds unnecessary cost and manufacturing complexity without providing any functional benefit.

If a ±5% tolerance is sufficient for the ball to perform its function, specifying anything tighter is a waste of resources.

How to Specify the Correct Tolerance

Base your decision on the specific functional requirements of your design.

- If your primary focus is a non-critical application (e.g., mixing media): A standard ±5% diameter tolerance is almost always sufficient and is the most cost-effective choice.

- If your primary focus is a sealing or mechanical application (e.g., valve seats, bearings): You must specify a precision tolerance (like ±0.005" or better) and a sphericity (TIR) based on your engineering analysis.

- If you are replacing a part or are unsure: Always consult the manufacturer's data sheet for the specific part number, as tolerances are ultimately defined on an item-by-item basis.

Ultimately, matching the specification to the true engineering need is the most effective approach to selecting your component.

Summary Table:

| Tolerance Grade | Typical Diameter Tolerance | Common Applications |

|---|---|---|

| Standard Grade | ±5% | Mixing media, general-purpose use where exact size is non-critical |

| Precision Grade | ±0.003" to ±0.005" | Valve seats, bearings, flow meters, sealing applications |

Need the Right PTFE Ball for Your Application?

At KINTEK, we manufacture high-quality PTFE components, including precision balls, seals, liners, and labware. Whether you require standard-grade mixing media or ultra-precise components for the semiconductor, medical, or industrial sectors, we deliver. Our expertise in custom fabrication ensures you get the exact tolerance and sphericity your design demands, from prototypes to high-volume orders.

Contact our experts today to discuss your specifications and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments