Beyond the frying pan, Teflon's role in the food and kitchenware industry is extensive and strategic. Its coating is applied not only to cookware but also to a wide range of small appliances like blenders and waffle irons, internal components of larger machines like dishwashers, and industrial equipment such as conveyor belts and food molds.

The core reason for Teflon's prevalence is its unique combination of properties. It solves the dual challenges of operational efficiency and product quality by providing a surface that is simultaneously non-stick, heat-resistant, easy to clean, and chemically inert.

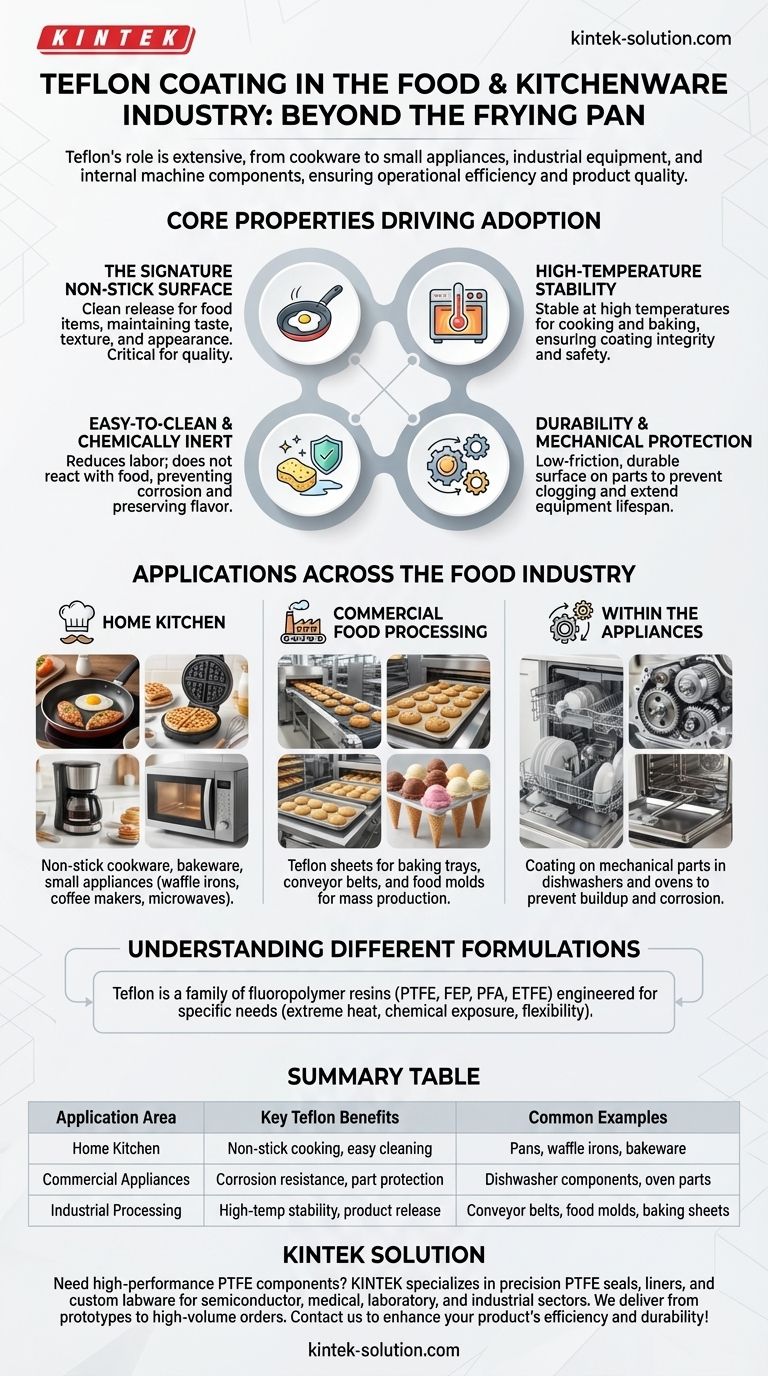

The Core Properties Driving Adoption

Teflon, a brand name for Polytetrafluoroethylene (PTFE), is valued for a specific set of characteristics that are exceptionally well-suited for food-related applications. These properties work in concert to improve processes in both home kitchens and industrial facilities.

The Signature Non-Stick Surface

The most recognized benefit is Teflon's non-stick, or "release," quality. This ensures that food items, from an egg in a skillet to muffins in a commercial mold, release cleanly without sticking.

This property is critical for maintaining the intended taste, texture, and appearance of food products.

High-Temperature Stability

Teflon coatings remain stable at the high temperatures required for cooking and industrial baking. This heat resistance ensures the coating's integrity and prevents the transfer of harmful chemicals to food during use.

Easy-to-Clean and Chemically Inert

The non-stick surface is inherently easy to clean, reducing labor in both domestic and commercial settings.

Furthermore, Teflon is chemically inert, meaning it does not react with food. This protects the equipment from corrosion and ensures the food's flavor is not altered.

Durability and Mechanical Protection

When applied to mechanical parts within appliances, Teflon coating provides a low-friction, durable surface. This helps prevent food particles from clogging gears and moving parts, extending the lifespan and reliability of the equipment.

Applications Across the Food Industry

Teflon's versatility allows it to be used in virtually every stage of food preparation, from small-scale home cooking to large-scale industrial manufacturing.

In the Home Kitchen

The most common application is non-stick cookware, including pans, skillets, and baking sheets.

It is also used to coat the interior surfaces of small appliances like waffle irons, coffee makers, and microwaves to simplify cooking and cleanup.

In Commercial Food Processing

In industrial settings, Teflon sheets are widely used as non-stick liners for baking trays and conveyor belts.

This application is crucial for mass-producing items like ice cream cones and baked goods, allowing for consistent quality and easy release from equipment.

Within the Appliances Themselves

A less visible but vital application is on the internal components of larger appliances.

In machines like dishwashers and ovens, Teflon coatings on mechanical parts prevent food buildup and corrosion, ensuring smooth and reliable operation over time.

Understanding the Different Formulations

It is important to recognize that "Teflon" is not a single substance but a family of related fluoropolymer resins. The specific formulation used is chosen based on the demands of the application.

Not All Coatings Are Identical

Different types of Teflon resins, such as PTFE, FEP, PFA, and ETFE, offer distinct advantages. Each is engineered to excel under specific conditions, whether it's extreme heat, chemical exposure, or the need for flexibility.

Matching the Resin to the Need

The coating required for a high-wear industrial conveyor belt is different from that needed for a home skillet. Manufacturers select the specific Teflon resin that provides the optimal balance of non-stick performance, durability, and heat resistance for the intended purpose.

Applying This to Your Needs

Understanding these applications helps clarify why certain products perform the way they do and what to look for based on your goals.

- If your primary focus is home cooking: The key benefit is the synergy between non-stick performance for better cooking results and the ease of cleanup afterward.

- If your primary focus is appliance design: Teflon provides a reliable solution for protecting internal components from food buildup while offering heat-resistant, easy-to-clean surfaces for the user.

- If your primary focus is industrial food production: The value lies in high-temperature stability and consistent release properties, which are critical for maintaining product quality and operational efficiency at scale.

Ultimately, Teflon's integration into the food industry is a clear example of how advanced material science can solve practical, everyday challenges.

Summary Table:

| Application Area | Key Teflon Benefits | Common Examples |

|---|---|---|

| Home Kitchen | Non-stick cooking, easy cleaning | Pans, waffle irons, bakeware |

| Commercial Appliances | Corrosion resistance, part protection | Dishwasher components, oven parts |

| Industrial Processing | High-temp stability, product release | Conveyor belts, food molds, baking sheets |

Need high-performance PTFE components for your food industry application? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We deliver custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact us today to discuss how our solutions can enhance your product's efficiency and durability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments