The fundamental reason PTFE O-rings are suitable for food production machinery is that virgin, additive-free Polytetrafluoroethylene (PTFE) is chemically inert and compliant with FDA regulations. This ensures the material will not react with or contaminate food products, safeguarding consumer health and product integrity.

While FDA compliance is the entry ticket, the true value of PTFE lies in its unique combination of chemical resistance, temperature tolerance, and non-stick properties that meet the rigorous demands of food processing environments.

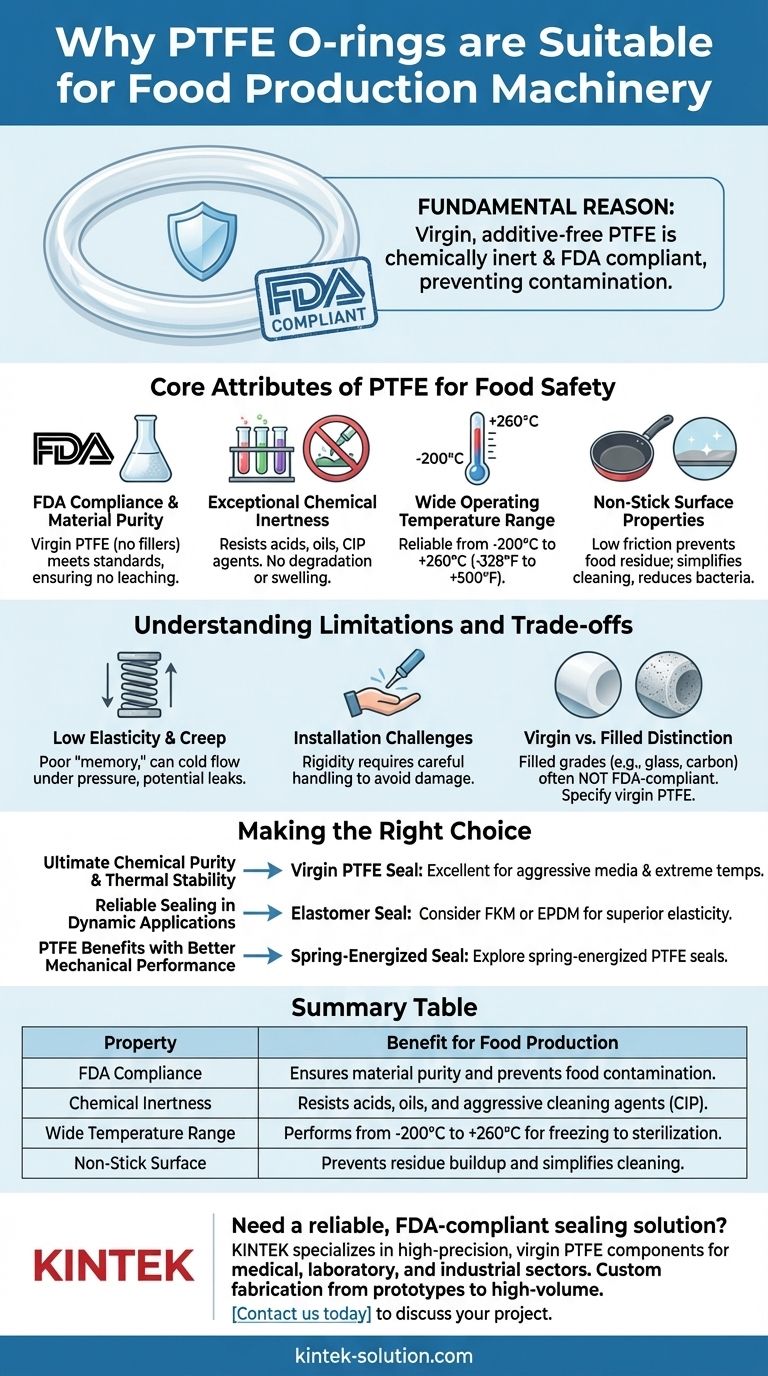

The Core Attributes of PTFE for Food Safety

To understand why PTFE is a trusted material in this industry, we must look beyond basic compliance and analyze the specific properties that make it so effective.

FDA Compliance and Material Purity

The U.S. Food and Drug Administration (FDA) has specific regulations for materials that come into contact with food. Virgin PTFE, meaning PTFE without any fillers or additives, meets these standards.

This compliance certifies that the material will not leach harmful substances into the food products it touches, preventing contamination and ensuring the final product is safe for consumption.

Exceptional Chemical Inertness

Food and beverage production involves a wide range of substances, from acidic fruit juices to fatty oils and aggressive cleaning agents used in Clean-in-Place (CIP) systems.

PTFE is virtually inert to almost all industrial chemicals. This means an O-ring made from virgin PTFE will not degrade, swell, or break down when exposed to these substances, ensuring a long service life and preventing seal failure.

Wide Operating Temperature Range

The food industry utilizes processes that span extreme temperatures, from flash freezing to high-temperature sterilization and cooking.

PTFE O-rings perform reliably across a vast temperature spectrum, typically from -200°C up to +260°C (-328°F to +500°F). This stability prevents the material from becoming brittle at low temperatures or degrading at high temperatures.

Non-Stick Surface Properties

PTFE is well-known for its low coefficient of friction, giving it a non-stick or "self-lubricating" surface.

In food machinery, this property is invaluable. It helps prevent food particles and other residues from adhering to the O-ring, which simplifies cleaning processes and minimizes potential sites for bacterial growth.

Understanding the Limitations and Trade-offs

No material is perfect for every application. While PTFE excels in chemical and thermal resistance, its mechanical properties present specific challenges that are critical to understand.

Low Elasticity and Creep

Unlike traditional rubber elastomers, PTFE is a relatively rigid plastic with poor "memory." It does not spring back to its original shape easily after being compressed.

This characteristic can lead to creep, or cold flow, where the material slowly deforms under constant pressure. In certain applications, this can eventually lead to a loss of sealing force and potential leaks.

Installation Challenges

The rigidity of PTFE can make installation more difficult compared to flexible rubber O-rings. Care must be taken to avoid scratching or damaging the seal during assembly, as any surface imperfections can create a leak path.

The Critical "Virgin vs. Filled" Distinction

To improve its mechanical properties like creep resistance, PTFE is often mixed with fillers such as glass, carbon, or bronze.

However, these "filled" grades of PTFE are often not FDA-compliant. It is absolutely critical to specify virgin, additive-free PTFE for any application involving direct food contact to ensure regulatory compliance.

Making the Right Choice for Your Application

Selecting the correct sealing material requires balancing the demands of the application with the properties of the material.

- If your primary focus is ultimate chemical purity and thermal stability in a static seal: Virgin PTFE is an excellent choice, offering unmatched resistance in environments with aggressive media or extreme temperatures.

- If your primary focus is reliable sealing in a dynamic or high-pressure application: Consider other FDA-compliant elastomers like FKM or EPDM, which offer superior elasticity and resistance to compression set.

- If you need the benefits of PTFE but require better mechanical performance: Explore spring-energized PTFE seals, which use a metal spring to overcome PTFE's low elasticity and maintain a consistent sealing force.

By understanding PTFE's unique strengths and its inherent limitations, you can confidently select the right sealing solution to ensure both product safety and operational reliability.

Summary Table:

| Property | Benefit for Food Production |

|---|---|

| FDA Compliance | Ensures material purity and prevents food contamination. |

| Chemical Inertness | Resists acids, oils, and aggressive cleaning agents (CIP). |

| Wide Temperature Range | Performs from -200°C to +260°C for freezing to sterilization. |

| Non-Stick Surface | Prevents residue buildup and simplifies cleaning. |

Need a reliable, FDA-compliant sealing solution for your food production machinery?

At KINTEK, we specialize in manufacturing high-precision, virgin PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment meets the highest standards of purity and performance.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit for your specific application.

Contact us today to discuss your project requirements and ensure product safety and operational reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs