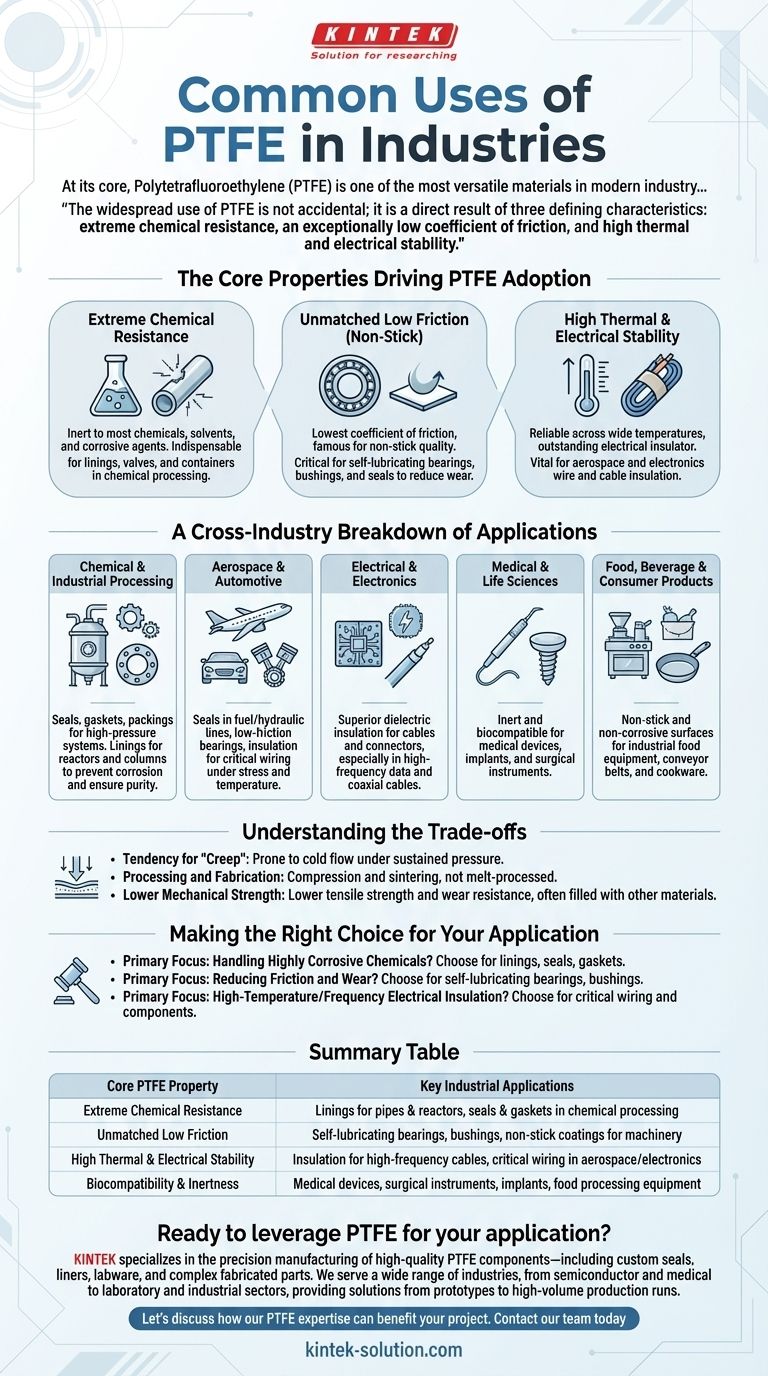

At its core, Polytetrafluoroethylene (PTFE) is one of the most versatile materials in modern industry due to its unique combination of properties. It is commonly used for high-performance seals, gaskets, and non-stick coatings, as well as critical components in the chemical, aerospace, electrical, and medical fields. Its applications range from lining pipes that carry corrosive acids to insulating high-frequency cables.

The widespread use of PTFE is not accidental; it is a direct result of three defining characteristics: extreme chemical resistance, an exceptionally low coefficient of friction, and high thermal and electrical stability. Understanding these properties is the key to understanding its role in any industry.

The Core Properties Driving PTFE Adoption

The value of PTFE in any application can almost always be traced back to one or more of its fundamental material properties. These attributes make it a problem-solver for engineering challenges that other materials cannot address.

### Extreme Chemical Resistance

PTFE is almost entirely inert, meaning it does not react with the vast majority of industrial chemicals, solvents, and corrosive agents.

This property makes it indispensable for lining pipes, valves, and containers in chemical processing and petrochemical plants, protecting equipment from degradation.

### Unmatched Low Friction (Non-Stick)

PTFE has one of the lowest coefficients of friction of any known solid material. This gives it its famous non-stick or lubricious quality.

While well-known in consumer cookware, this property is critical in industrial settings for creating self-lubricating bearings, bushings, and seals that reduce wear and energy consumption in machinery.

### High Thermal & Electrical Stability

PTFE can perform reliably across an exceptionally wide temperature range without degrading. It is also an outstanding electrical insulator.

This combination is vital in aerospace and electronics, where it is used for wire and cable insulation, particularly in high-frequency or high-temperature environments.

A Cross-Industry Breakdown of Applications

The core properties of PTFE translate into specific, high-value uses across nearly every major industrial sector.

### Chemical & Industrial Processing

In environments dealing with aggressive media, PTFE is the material of choice. It is fabricated into seals, gaskets, and packings to prevent leaks in high-pressure systems. It is also used to line reactors and columns, ensuring purity and preventing corrosion.

### Aerospace & Automotive

Both sectors rely on PTFE for components that must perform under stress. It is used for seals in fuel systems and hydraulic lines, low-friction bearings, and insulation for critical wiring where temperature stability and reliability are paramount.

### Electrical & Electronics

As a superior dielectric material, PTFE is fundamental to the electronics industry. Its primary use is as insulation for cables and connectors, especially in high-performance applications like data and coaxial cables where signal integrity is essential.

### Medical & Life Sciences

Due to its inertness and biocompatibility, PTFE is trusted for medical applications. It is used in manufacturing medical devices, implants, and surgical instruments that must not react with bodily fluids.

### Food, Beverage & Consumer Products

The non-stick and non-corrosive nature of PTFE makes it ideal for food processing. It is used for non-stick surfaces on industrial food equipment, conveyor belts, and, most famously, as the coating on non-stick cookware.

Understanding the Trade-offs

While incredibly useful, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations, which often involve a trade-off between its unique benefits and its mechanical characteristics.

### Tendency for "Creep"

PTFE is a relatively soft material. Under sustained pressure (compressive load), it can be prone to "creep" or cold flow, meaning it can slowly deform over time. This must be accounted for in high-load structural designs.

### Processing and Fabrication

Unlike many common plastics, PTFE cannot be melt-processed. It is typically shaped through a process of compression and sintering, which can be more complex and costly than standard injection molding.

### Lower Mechanical Strength

Compared to engineering plastics like PEEK or Nylon, PTFE has lower tensile strength and wear resistance. In applications with high mechanical abrasion, it is often "filled" with other materials like glass or carbon to improve its durability.

Making the Right Choice for Your Application

Selecting the right material requires aligning its strengths with your primary goal. The decision to use PTFE becomes clear when you focus on the problem you need to solve.

- If your primary focus is handling highly corrosive chemicals: PTFE's chemical inertness makes it one of the safest and most reliable choices for linings, seals, and gaskets.

- If your primary focus is reducing friction and wear in moving parts: The exceptionally low friction of PTFE makes it ideal for self-lubricating bearings, bushings, and surface coatings.

- If your primary focus is high-temperature or high-frequency electrical insulation: PTFE's thermal stability and excellent dielectric properties provide unmatched performance for critical wiring and electronic components.

By understanding its fundamental strengths and limitations, you can effectively leverage PTFE to solve some of the most demanding industrial challenges.

Summary Table:

| Core PTFE Property | Key Industrial Applications |

|---|---|

| Extreme Chemical Resistance | Linings for pipes & reactors, seals & gaskets in chemical processing |

| Unmatched Low Friction | Self-lubricating bearings, bushings, non-stick coatings for machinery |

| High Thermal & Electrical Stability | Insulation for high-frequency cables, critical wiring in aerospace/electronics |

| Biocompatibility & Inertness | Medical devices, surgical instruments, implants, food processing equipment |

Ready to leverage PTFE for your application?

PTFE's unique properties can solve your most demanding challenges in chemical resistance, friction reduction, and thermal/electrical stability. KINTEK specializes in the precision manufacturing of high-quality PTFE components—including custom seals, liners, labware, and complex fabricated parts.

We serve a wide range of industries, from semiconductor and medical to laboratory and industrial sectors, providing solutions from prototypes to high-volume production runs.

Let's discuss how our PTFE expertise can benefit your project. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do additives and fillers specialize PTFE-based PCB materials? Tailor High-Frequency Circuit Performance

- Why are PTFE liners considered cost-effective? Maximize Uptime and Reduce Long-Term Costs

- What are the advantages of PTFE over other polymers in CNC machining? Achieve Superior Performance in Demanding Applications

- What are the features of PTFE with a Proprietary Organic Fill? Protect Soft Metals with Low-Friction Performance

- What are the main types of PTFE lined valves? Find the Right Valve for Your Corrosive Application

- What advantages do PTFE gasket materials offer? Unmatched Chemical & Thermal Resistance

- What are some common structural types of PTFE gaskets? Choose the Right Seal for Your Application

- What are the tolerances for PTFE balls based on size? Precision vs. Standard Grade Explained