At its core, PTFE's flexibility is the source of its remarkable durability and adaptability. This physical property allows it to absorb energy, conform to surfaces, and resist failure in environments where rigid materials would crack or break. It maintains this resilience across an exceptionally wide range of temperatures, from cryogenic lows to high-heat applications.

The critical takeaway is that PTFE's flexibility is not a single characteristic but a spectrum. It translates directly into mechanical resilience, but its expression—from the structural rigidity of standard PTFE to the soft compressibility of expanded PTFE (ePTFE)—must be matched to the specific demands of the application.

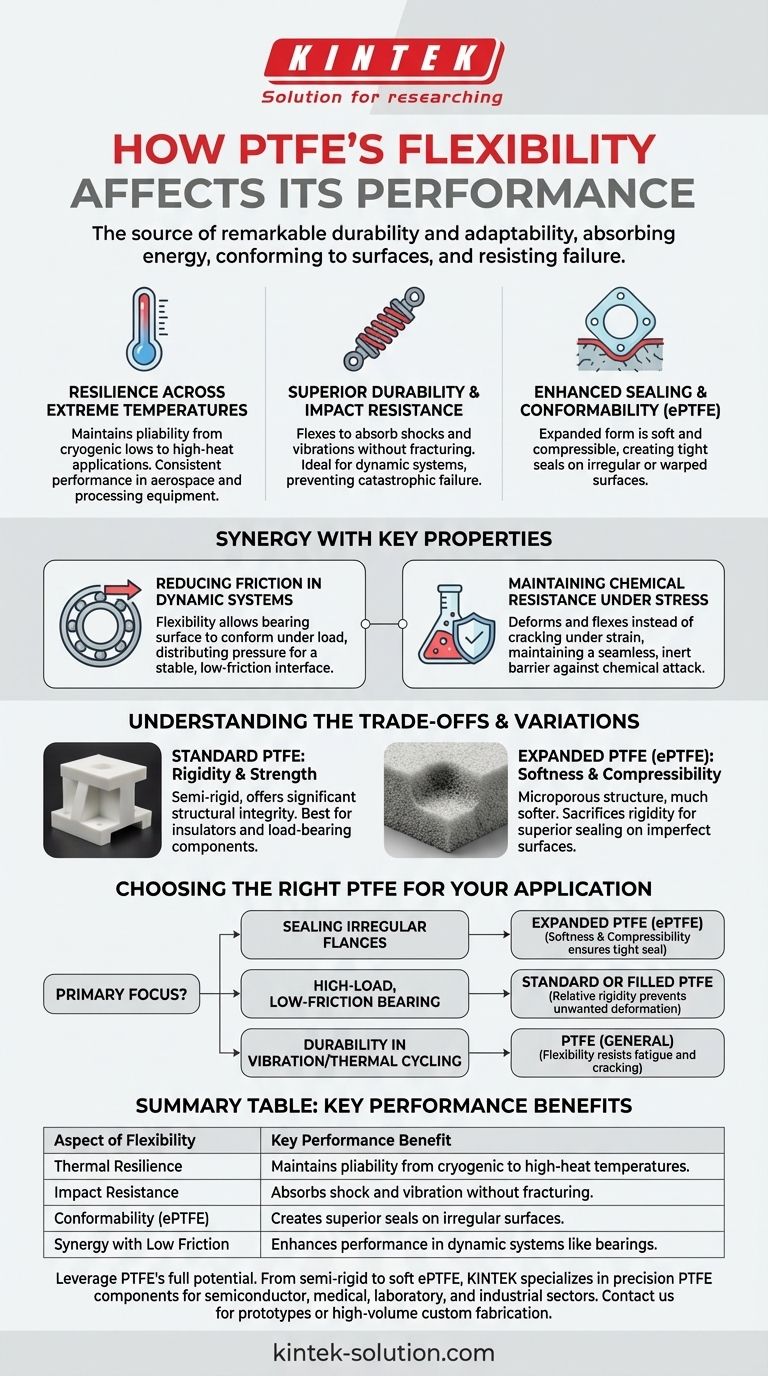

The Core Performance Benefits of Flexibility

The inherent flexibility of the Polytetrafluoroethylene polymer is a primary driver of its performance in demanding industrial and mechanical contexts.

Resilience Across Extreme Temperatures

Unlike many polymers that become brittle in the cold or deform excessively under heat, PTFE remains pliable. This thermal stability ensures consistent performance whether it's used in aerospace applications or high-temperature processing equipment.

Superior Durability and Impact Resistance

This material's ability to flex allows it to absorb shocks, vibrations, and physical impacts without fracturing. This makes it ideal for dynamic systems where stress and movement are constant, preventing catastrophic material failure.

Enhanced Sealing and Conformability

In its expanded form (ePTFE), the material is exceptionally soft and compressible. This allows it to create a tight seal by conforming perfectly to irregular, pitted, or warped surfaces, which is something a more rigid gasket material cannot do.

How Flexibility Complements Other Key Properties

PTFE’s flexibility does not exist in isolation. It works in synergy with its other well-known properties to create a uniquely high-performance material.

Reducing Friction in Dynamic Systems

In components like bearings, PTFE's low coefficient of friction is legendary. Its flexibility adds to this by allowing the bearing surface to conform slightly under load, distributing pressure evenly and maintaining a stable, low-friction interface.

Maintaining Chemical Resistance Under Stress

A rigid material under mechanical stress can develop micro-cracks, creating pathways for chemical attack. Because PTFE deforms and flexes instead of cracking, it maintains its seamless, chemically inert barrier even when subjected to physical strain.

Understanding the Trade-offs and Variations

Not all PTFE is the same, and its degree of flexibility is a key variable. Choosing the wrong type can lead to suboptimal performance.

Standard PTFE: Rigidity and Strength

Standard, or virgin, PTFE is best described as semi-rigid. While still flexible compared to metals or ceramics, it offers significant structural integrity. This makes it suitable for components like insulators or certain types of bearings where maintaining shape under load is critical.

Expanded PTFE (ePTFE): Softness and Compressibility

The manufacturing process can be altered to create expanded PTFE, a material with a microporous structure that is much softer and more conformable. This variant sacrifices some rigidity for superior sealing capabilities, especially on imperfect surfaces.

Choosing the Right PTFE for Your Application

Selecting the correct form of PTFE requires a clear understanding of your primary engineering goal.

- If your primary focus is sealing irregular or damaged flanges: Expanded PTFE (ePTFE) is the correct choice, as its softness and compressibility will ensure a tight seal.

- If your primary focus is a high-load, low-friction bearing: A standard or filled PTFE is superior, as its relative rigidity will prevent unwanted deformation under pressure.

- If your primary focus is durability in an environment with vibration or thermal cycling: PTFE's general flexibility makes it an excellent choice over more brittle plastics, as it will resist fatigue and cracking.

Ultimately, understanding the specific type of flexibility you need is key to leveraging PTFE's full potential.

Summary Table:

| Aspect of Flexibility | Key Performance Benefit |

|---|---|

| Thermal Resilience | Maintains pliability from cryogenic to high-heat temperatures. |

| Impact Resistance | Absorbs shock and vibration without fracturing. |

| Conformability (ePTFE) | Creates superior seals on irregular surfaces. |

| Synergy with Low Friction | Enhances performance in dynamic systems like bearings. |

Leverage PTFE's full potential for your application. The right type of PTFE—from semi-rigid for structural components to soft ePTFE for critical seals—is crucial for optimal performance. At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume custom fabrication, our expertise ensures you get a solution that perfectly balances flexibility with strength. Contact us today to discuss your project requirements! Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance