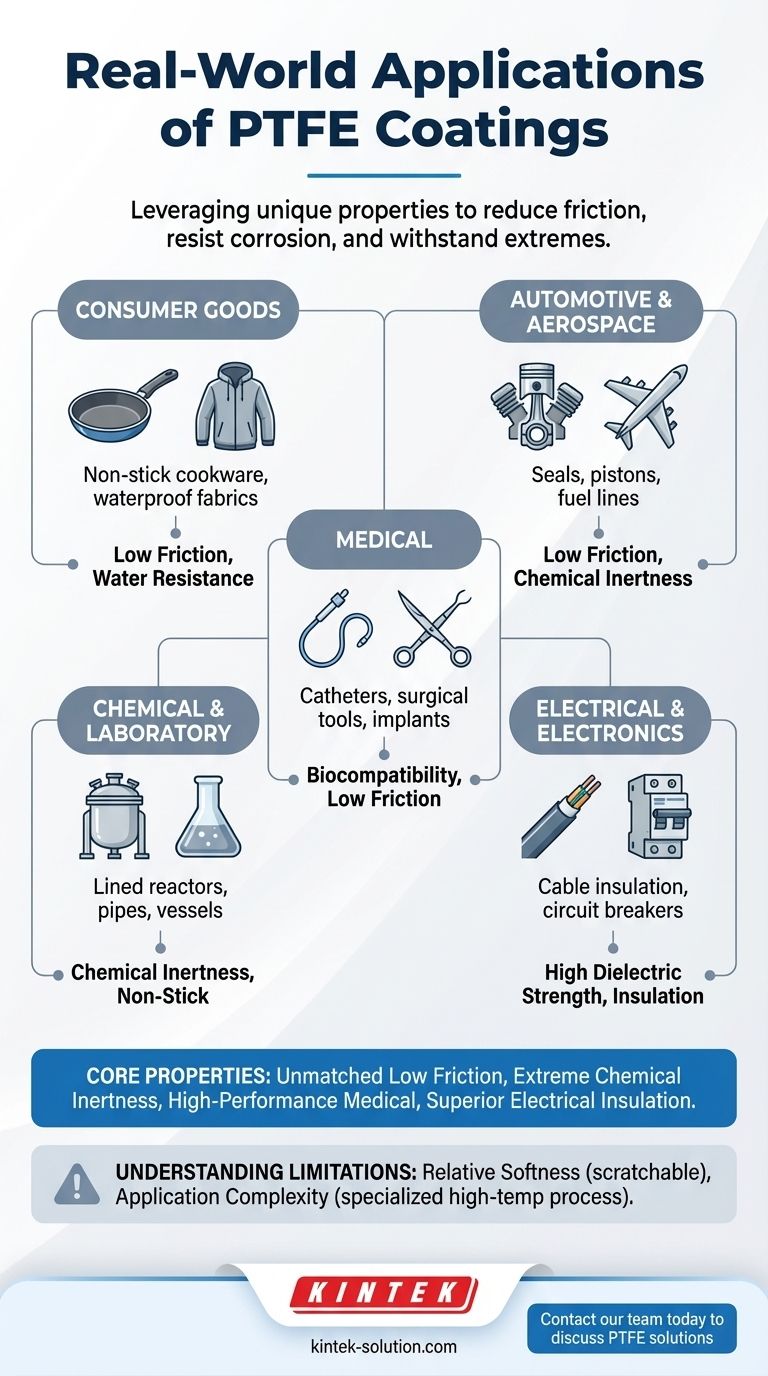

In the modern world, Polytetrafluoroethylene (PTFE) coatings are used in a vast range of applications, from everyday non-stick cookware and waterproof clothing to critical components in the aerospace, medical, and automotive industries. These coatings are leveraged for their unique ability to reduce friction, resist chemical corrosion, and withstand extreme temperatures, making them essential for enhancing performance and safety.

The true value of PTFE coatings isn't a single feature, but a powerful combination of properties. Understanding how its low friction, chemical inertness, and temperature resistance are applied is key to recognizing its role as a problem-solver across nearly every major industry.

Why PTFE is So Widely Used: The Core Properties

The versatility of PTFE stems from a few fundamental characteristics. Different industries emphasize different properties to solve specific engineering challenges.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material, a property often compared to wet ice on wet ice. This makes surfaces incredibly slick.

This is the principle behind non-stick cookware and industrial food processing equipment, where it prevents materials from adhering, simplifying both use and cleaning.

In automotive and industrial machinery, this property is used on gears, pistons, valves, and slide plates. The coating reduces wear and tear, lowers energy consumption, and ensures smoother, more reliable operation.

Extreme Chemical Inertness

PTFE is non-reactive and resists corrosion from the vast majority of chemicals and solvents. This makes it an ideal protective barrier in harsh environments.

This is critical in chemical processing plants and laboratory research, where PTFE is used to line reactors, pipes, tubes, and vessels. It prevents corrosion of the equipment and contamination of the substances being handled.

The same principle applies to fuel and hydraulic lines in vehicles and aircraft, ensuring the smooth flow of aggressive fluids without degrading the components.

High-Performance Medical Applications

The medical field leverages PTFE's properties to improve patient safety and device performance. Its non-reactive nature means it is highly biocompatible and unlikely to cause an adverse reaction within the body.

On catheters and guidewires, the low-friction coating allows for smoother insertion and navigation through blood vessels, minimizing patient discomfort and trauma.

Surgical instruments are often coated to prevent biological material from sticking, which makes them far easier to clean and sterilize, ultimately reducing the risk of infection. PTFE is also used for medical implants and graft materials.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, meaning it does not conduct electricity. This property, known as high dielectric strength, makes it invaluable for electrical and electronic applications.

It is commonly used for cable insulation and wiring, especially in high-performance aerospace and computing applications where signal integrity is paramount.

Larger components in the power grid, such as transformers and circuit breakers, also rely on PTFE coatings to prevent electrical arcing and ensure safe operation.

Understanding the Limitations

While incredibly useful, PTFE coatings are not a universal solution. Acknowledging their trade-offs is crucial for proper application.

Relative Softness

PTFE is a relatively soft material. This is why non-stick pans can be easily scratched by metal utensils, which compromises the coating's integrity. In industrial applications, it may not be suitable for high-load, abrasive environments without being reinforced.

Application Complexity

Applying a PTFE coating is a specialized industrial process. The material, which comes in powder or liquid form, must be applied evenly using methods like electrostatic spraying and then cured at high temperatures. This process restricts the types of materials that can be coated and adds to manufacturing complexity and cost.

Making the Right Choice for Your Goal

The decision to use a PTFE coating depends entirely on the primary problem you need to solve. By focusing on the material's core strengths, you can determine its suitability for your specific application.

- If your primary focus is reducing wear and energy loss: Leverage PTFE's extremely low friction for mechanical components like gears, bearings, and pistons.

- If your primary focus is preventing contamination and corrosion: Utilize its chemical inertness for lining pipes, vessels, and containers in chemical, food, or laboratory settings.

- If your primary focus is enhancing safety and biocompatibility: Apply its non-stick and non-reactive properties to medical devices like catheters, surgical tools, and implants.

- If your primary focus is electrical safety and signal integrity: Depend on its high dielectric strength for insulating critical cables, wires, and electronic components.

Ultimately, PTFE coatings serve as a powerful tool for engineers and product designers to overcome friction, corrosion, and contamination in the most demanding environments.

Summary Table:

| Industry | Key Application | Primary PTFE Property Used |

|---|---|---|

| Consumer Goods | Non-stick cookware, waterproof fabrics | Low friction, water resistance |

| Automotive & Aerospace | Seals, pistons, fuel lines | Low friction, chemical inertness |

| Medical | Catheters, surgical tools, implants | Biocompatibility, low friction |

| Chemical & Laboratory | Lined reactors, pipes, vessels | Chemical inertness, non-stick |

| Electrical & Electronics | Cable insulation, circuit breakers | High dielectric strength, insulation |

Need high-performance PTFE components for your application?

KINTEK specializes in the precision manufacturing of custom PTFE seals, liners, labware, and more. Whether you require prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures components that deliver superior chemical resistance, low friction, and reliability.

Contact our team today to discuss how our PTFE solutions can enhance your product's performance and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry