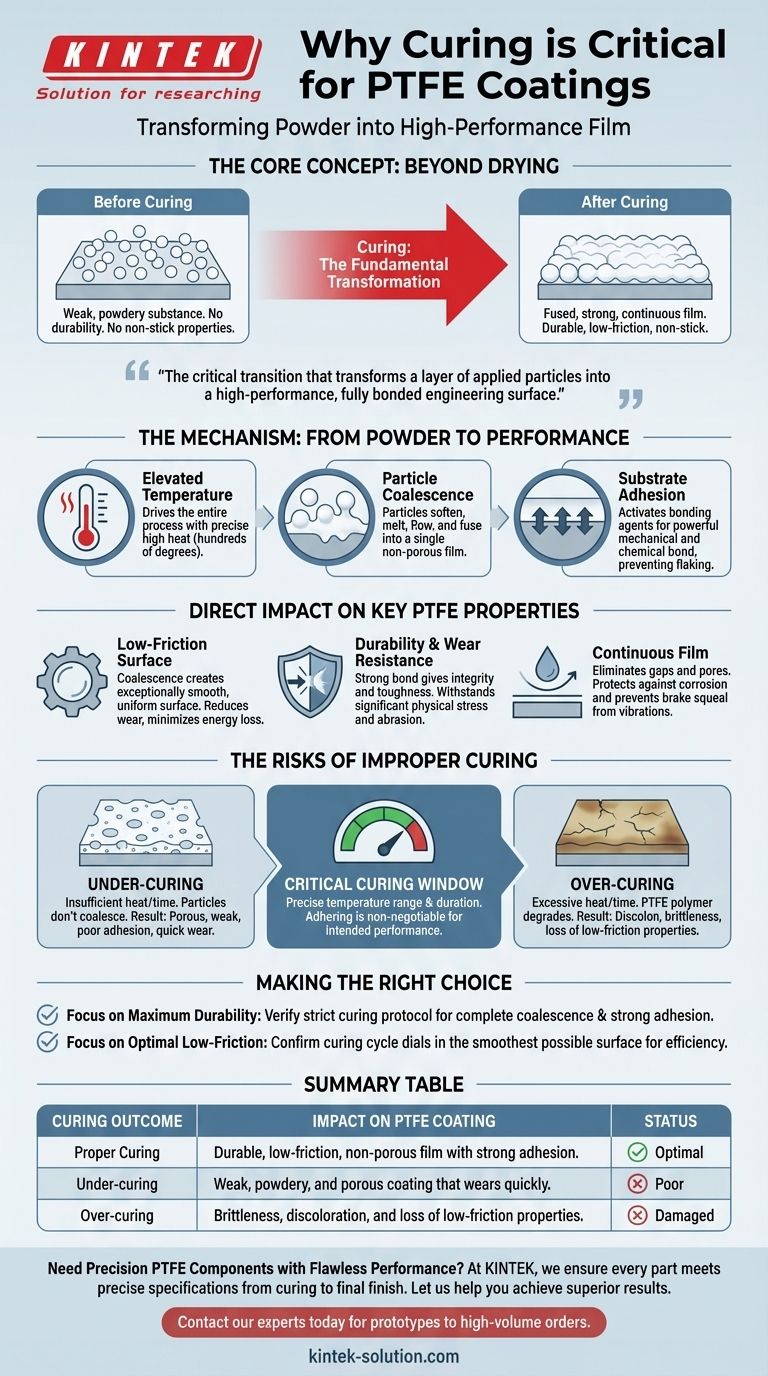

In PTFE coating manufacturing, curing is not merely a drying stage; it is the fundamental process that creates the functional coating itself. Curing at high temperatures is essential because it melts the individual PTFE particles, causing them to fuse together and bond securely to the underlying material. Without this critical step, the applied layer would remain a weak, powdery substance with none of the durability, low-friction, or non-stick properties for which PTFE is known.

The curing process is the critical transition that transforms a layer of applied particles into a high-performance, fully bonded engineering surface. It is the specific moment when the coating's theoretical benefits, like durability and low friction, become a physical reality.

The Mechanism of Curing: From Powder to Performance Film

The importance of curing lies in the physical and chemical transformation that occurs at a microscopic level. It is a precisely controlled process that goes far beyond simple drying.

The Role of Elevated Temperature

The entire process is driven by heat. PTFE coatings must be brought to a specific temperature, often several hundred degrees, to initiate the necessary changes in the material.

Particle Coalescence

At the correct curing temperature, the individual PTFE particles soften and melt. This allows them to flow together and fuse, a process known as coalescence, which forms a single, continuous, and non-porous film.

Substrate Adhesion

Simultaneously, the heat activates bonding agents within the coating system. These agents create a powerful mechanical and chemical bond between the new PTFE film and the substrate, ensuring the coating will not chip or flake off during use.

How Curing Directly Impacts Key PTFE Properties

A properly executed curing cycle is directly responsible for creating the high-performance characteristics that make PTFE valuable in applications from engines to brake systems.

Creating a Low-Friction Surface

The coalescence of particles creates an exceptionally smooth and uniform surface. This microscopic smoothness is fundamental to achieving the low coefficient of friction that reduces wear in moving parts and minimizes fuel consumption in engines.

Ensuring Durability and Wear Resistance

The strong bond formed with the substrate during curing is what gives the coating its integrity and toughness. A well-cured coating can withstand significant physical stress and abrasion without failing.

Achieving a Continuous Film

The fusion of PTFE particles eliminates gaps and pores. This creates a solid barrier that enhances the coating's performance, protecting the underlying component from corrosive elements and preventing "brake squeal" caused by high-frequency vibrations from wear.

Understanding the Trade-offs: The Risks of Improper Curing

The curing process is not forgiving. Deviating from the precise time and temperature specifications leads to immediate and significant coating failure.

The Impact of Under-curing

If the coating does not reach the required temperature or is not held there long enough, the PTFE particles will fail to coalesce properly. This results in a porous, weak film with poor adhesion that will quickly wear away.

The Danger of Over-curing

Exceeding the recommended temperature or time can be equally damaging. Excessive heat can degrade the PTFE polymer, causing discoloration and brittleness, which compromises its low-friction properties and durability.

The Critical Curing Window

For every PTFE coating formulation, there is a specific "curing window"—a precise temperature range and duration. Adhering to this window is non-negotiable for achieving the intended performance and service life of the coated part.

Making the Right Choice for Your Goal

Understanding the role of curing is essential when specifying or evaluating a PTFE coating for any application.

- If your primary focus is maximum durability and wear resistance: You must verify the coating process adheres to a strict curing protocol that guarantees complete particle coalescence and strong substrate adhesion.

- If your primary focus is optimal low-friction performance: Confirm that the curing cycle is dialed in to produce the smoothest possible surface, as this directly translates to reduced energy loss and enhanced efficiency.

Ultimately, recognizing that curing defines the final quality of the coating is the key to ensuring the component delivers on its engineering promise.

Summary Table:

| Curing Outcome | Impact on PTFE Coating |

|---|---|

| Proper Curing | Creates a durable, low-friction, non-porous film with strong adhesion. |

| Under-curing | Results in a weak, powdery, and porous coating that wears quickly. |

| Over-curing | Causes brittleness, discoloration, and loss of low-friction properties. |

Need Precision PTFE Components with Flawless Performance?

At KINTEK, we understand that the integrity of a PTFE coating—from the curing process to the final finish—is paramount to your product's success. We specialize in the custom fabrication of high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures every part meets the precise specifications required for optimal durability, low friction, and chemical resistance.

Let us help you achieve superior results. Contact our experts today to discuss your project needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs