At its core, the non-stick property of Polytetrafluoroethylene (PTFE) is a direct result of its unique molecular structure. The exceptionally strong and stable bonds between carbon and fluorine atoms create a chemically inert surface with extremely low surface energy, which prevents other materials from adhering to it.

The key is not just what PTFE is made of, but how it is built. Fluorine atoms form a tight, non-reactive "shield" around a carbon backbone, creating a surface that repels nearly everything it touches.

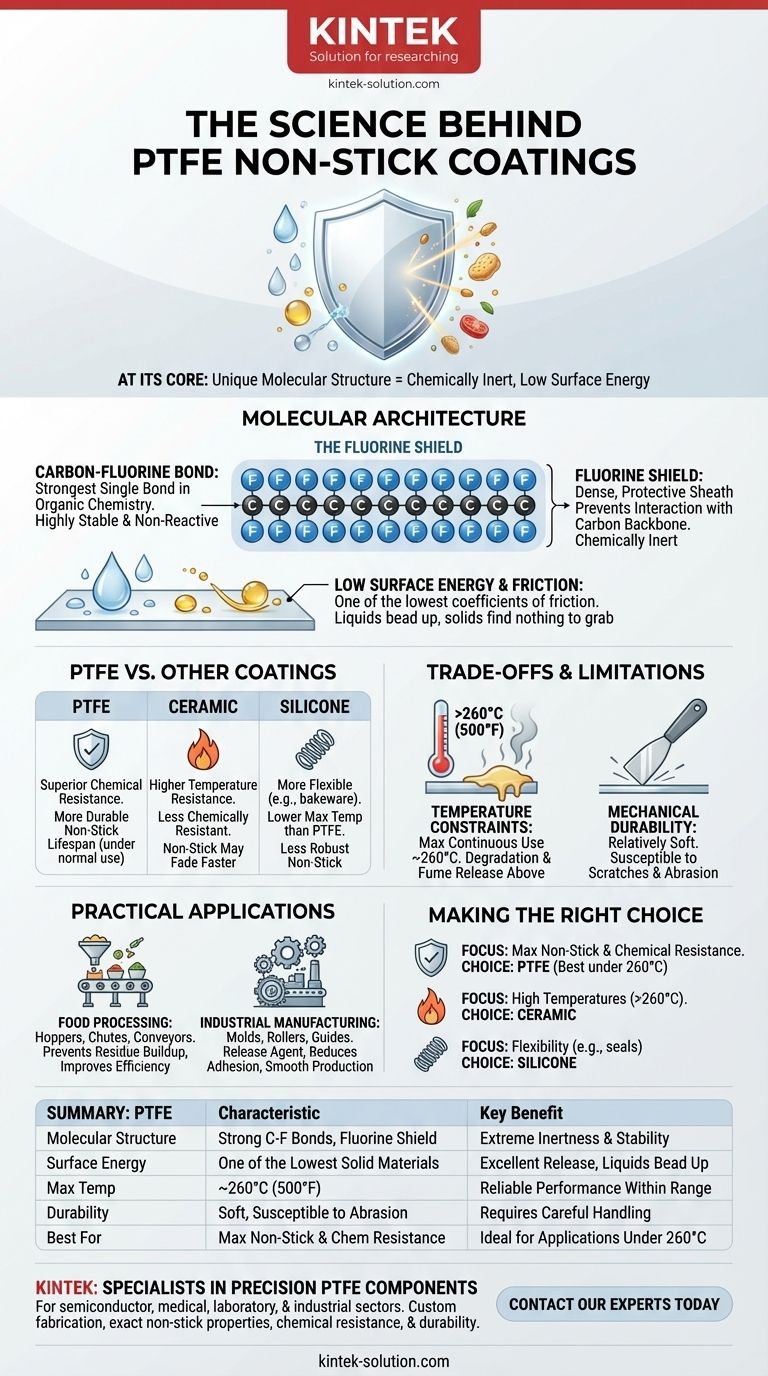

The Molecular Architecture of a Non-Stick Surface

To truly understand PTFE's performance, we must look at its atomic arrangement. The properties we observe on a macroscopic level are a direct consequence of its molecular design.

The Carbon-Fluorine Bond

The bond between a carbon atom and a fluorine atom is one of the strongest single bonds in organic chemistry. This incredible strength makes the PTFE molecule highly stable and non-reactive.

The "Fluorine Shield"

In a PTFE molecule, the carbon atoms form a long chain (a polymer backbone). Each carbon atom is completely surrounded by larger fluorine atoms, creating a dense, protective sheath.

This "fluorine shield" effectively prevents other molecules from getting close enough to interact with the carbon backbone, rendering the surface chemically inert.

Low Surface Energy and Friction

This molecular structure results in one of the lowest coefficients of friction and lowest surface tensions of any known solid material.

Because the surface has such low energy, other substances—like water, oil, or food—are not attracted to it. Instead of wetting the surface, liquids bead up and roll off, and solids find almost nothing to grab onto, giving PTFE its signature "slippery" and non-stick feel.

How PTFE Compares to Other Coatings

While PTFE is famous for being non-stick, it is not the only material used for this purpose. Understanding its position relative to alternatives is key to proper material selection.

vs. Ceramic Coatings

PTFE offers superior chemical resistance and is generally more durable in terms of its non-stick lifespan under normal use.

Ceramic coatings can typically withstand higher temperatures than PTFE but may be less chemically resistant and can lose their non-stick properties more quickly over time.

vs. Silicone Coatings

PTFE provides better non-stick release and operates at a higher maximum temperature than most silicone-based coatings.

Silicone coatings are more flexible than PTFE, which can be an advantage in certain applications like bakeware. However, their non-stick performance is generally not as robust.

Understanding the Trade-offs and Limitations

No material is perfect. Acknowledging the trade-offs associated with PTFE is critical for successful application and avoiding failure.

Temperature Constraints

PTFE coatings have a maximum continuous use temperature of approximately 260°C (500°F). Above this temperature, the coating can begin to degrade, releasing fumes and losing its non-stick integrity.

Mechanical Durability

While chemically robust, PTFE is a relatively soft material. Coatings are typically applied in very thin layers, often between 0.0003 and 0.0008 inches.

This makes them susceptible to scratches and abrasion from hard utensils or abrasive cleaning, which can compromise the non-stick surface.

Practical Applications Beyond Cookware

The unique properties of PTFE make it invaluable across a wide range of industries, far beyond the kitchen.

Food Processing and Packaging

In commercial food processing, PTFE coatings on hoppers, chutes, and conveyors prevent residue buildup. This improves efficiency, reduces waste, and simplifies cleaning operations.

Industrial Manufacturing

On industrial machinery, PTFE coatings act as a release agent for molds and reduce product adhesion on rollers and guides. This is critical in industries from plastics to textiles, ensuring smooth and continuous production.

Making the Right Choice for Your Goal

Selecting the correct coating depends entirely on the primary demands of your application.

- If your primary focus is maximum non-stick release and chemical resistance: PTFE remains the benchmark and is the superior choice for most applications under 260°C (500°F).

- If your primary focus is withstanding temperatures above 260°C (500°F): A ceramic-based coating is a more suitable and safer option.

- If your primary focus is flexibility, such as for bakeware or seals: A silicone-based coating may provide the best balance of properties.

By understanding the fundamental science behind PTFE, you can confidently select the right material to achieve your specific performance goals.

Summary Table:

| Property | PTFE Characteristic | Key Benefit |

|---|---|---|

| Molecular Structure | Strong Carbon-Fluorine bonds & "Fluorine Shield" | Extreme chemical inertness and stability |

| Surface Energy | One of the lowest of any solid | Excellent release properties; liquids bead up |

| Max Temp | ~260°C (500°F) | Reliable performance within its range |

| Durability | Soft; susceptible to abrasion | Requires careful handling to maintain coating |

| Best For | Maximum non-stick release & chemical resistance | Ideal for applications under 260°C |

Need a high-performance, non-stick solution for your application?

At KINTEK, we specialize in precision PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact non-stick properties, chemical resistance, and durability your project demands.

Let us help you achieve your performance goals. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the key benefits of PTFE (Teflon) gaskets? Superior Chemical & Temperature Resistance

- Which regulatory standards do PTFE rotary shaft seals comply with? Ensure Compliance for Your Application

- What is a PTFE coated O-ring? A Hybrid Seal for Low Friction & Chemical Resistance

- What industries can benefit from PTFE-free bushings? Automotive, Aerospace, and Heavy Machinery Solutions

- Why is PTFE valuable in aerospace applications? Key Benefits for Safer, Lighter Aircraft

- How are glass-filled PTFE rods applied in the automotive industry? Enhance Performance & Reliability

- What are the limitations of machining Teflon (PTFE)? Overcome Challenges for Precision Parts

- How can sticking or hard operation of a PTFE butterfly valve be resolved? A 3-Step Guide to Restore Smooth Performance